Laser welding method and laser welding apparatus

A technology of laser welding and laser beam, which is applied in the direction of laser welding equipment, welding equipment, conductors, etc., can solve the problems of decreased welding strength and increased resistance, achieve a good welding state, and prevent the formation of air holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] A laser welding method and a laser welding device according to the embodiments will be described below. First, a laser welding device according to this embodiment will be described. After that, the laser welding method will be explained.

[0031] (laser welding device)

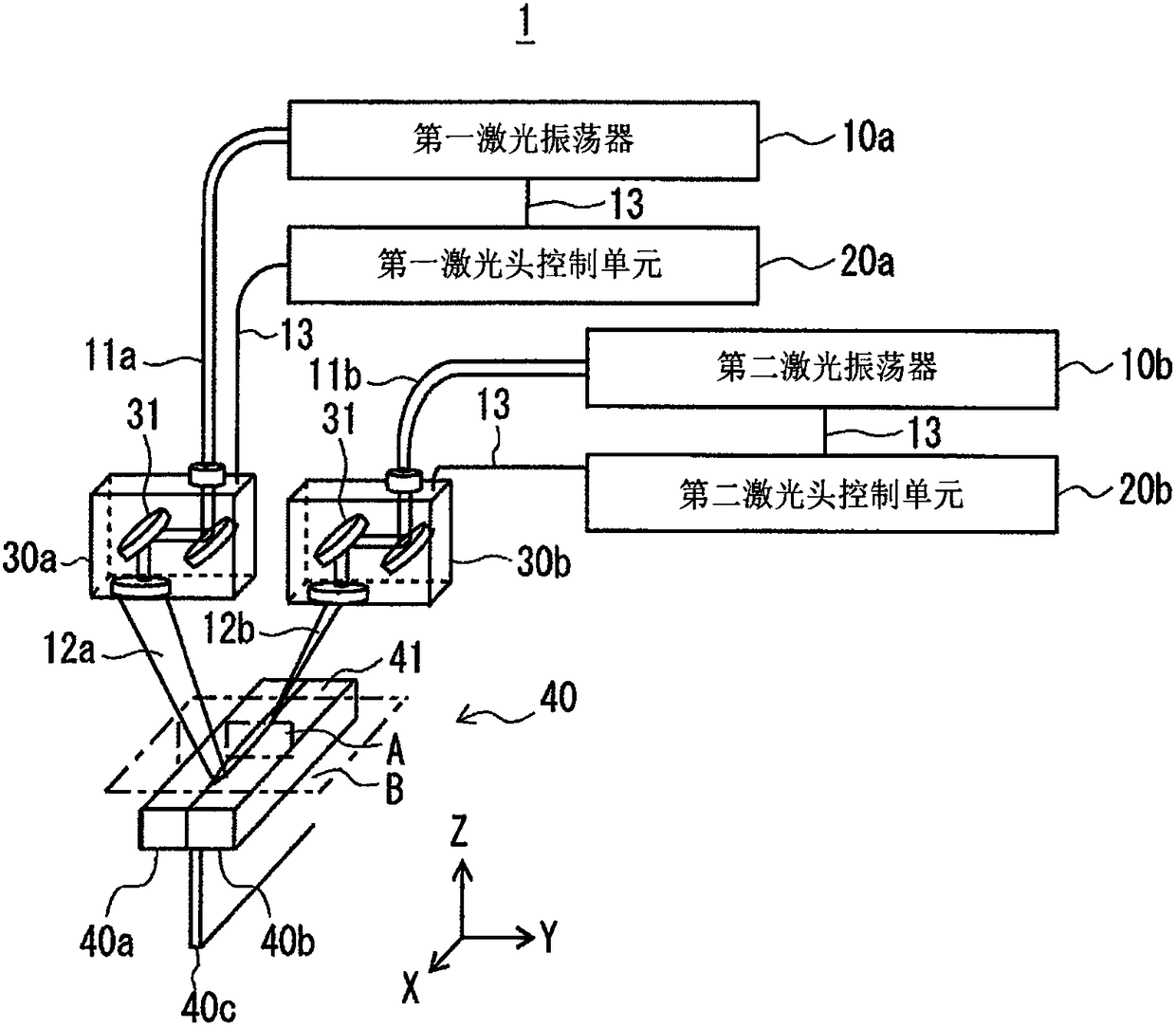

[0032] First, the configuration of the laser welding device will be described. figure 1 is a configuration diagram showing an example of the configuration of the laser welding device according to the embodiment.

[0033] Such as figure 1 As shown, the laser welding device 1 includes a first laser oscillator 10a, a second laser oscillator 10b, a first laser head control unit 20a, a second laser head control unit 20b, a first welding head 30a and a second welding head 30b. The first laser oscillator 10a is connected to the first welding head 30a through an optical cable 11a. The second laser oscillator 10b is connected to the second welding head 30b through an optical cable 11b. The first laser osci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com