Experimental device for flexible closed-loop control over ERW pipe weld joint opening angles

A closed-loop control and experimental device technology, applied in welding monitoring devices, welding power sources, manufacturing tools, etc., can solve problems such as the inability to obtain the shape of the opening angle intuitively, the large resilience of materials, and the inability to guarantee the size and shape of the opening angle. The effect of minimizing welding defects, ensuring accuracy, and improving the quality of welded pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

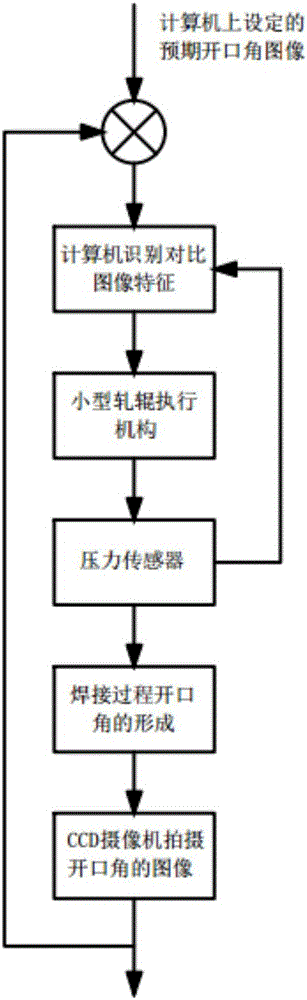

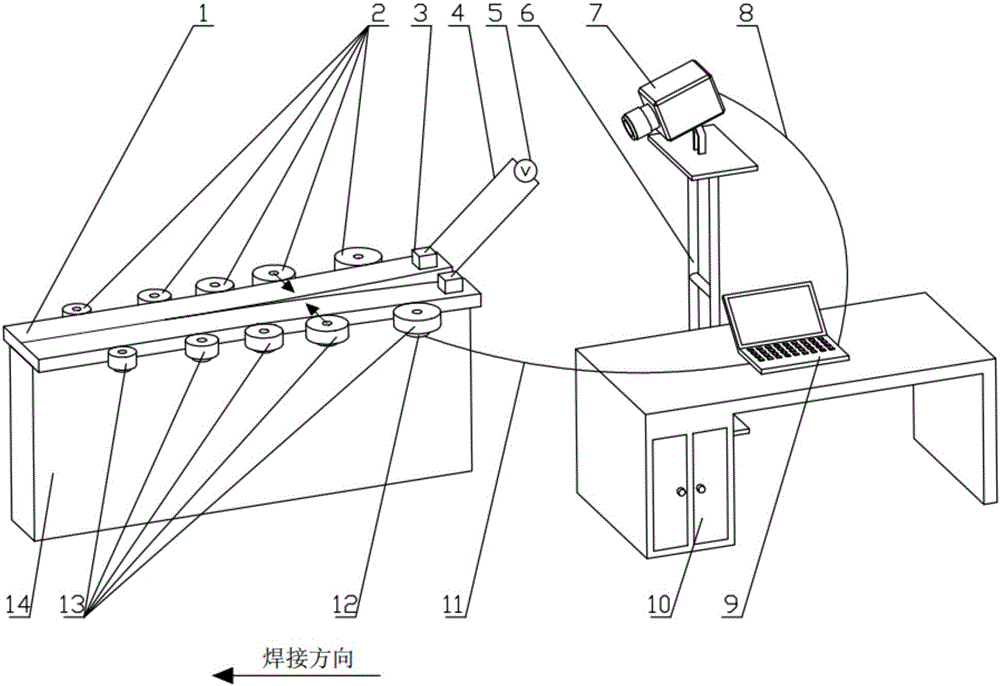

[0013] Such as figure 1 As shown, the expected opening angle image set on the computer and the opening angle image taken by the CCD camera are identified on the computer to compare the image features, and the computer controls the small roll actuator, by changing the axial distance between every two pairs of small rolls or The radial distance between each pair of small rolls is used to change the size of the extrusion force, thereby adjusting the size and shape of the opening angle. The extrusion force monitored by the pressure sensor on the small rolls is fed back to the computer. During the welding process, the opening angle After forming, the image captured by the CCD camera will also be fed back to the computer.

[0014] Such as figure 2 As shown, one end of the circuit 4 is in electrical contact with the high-frequency generator and its output d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com