Edible salt production equipment

A kind of production equipment and edible salt technology, applied in the field of edible salt production, can solve problems such as difficult discharge, pipeline blockage, unresolved salt crystallization, etc., and achieve the effects of saving energy, facilitating energy saving, and accelerating output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

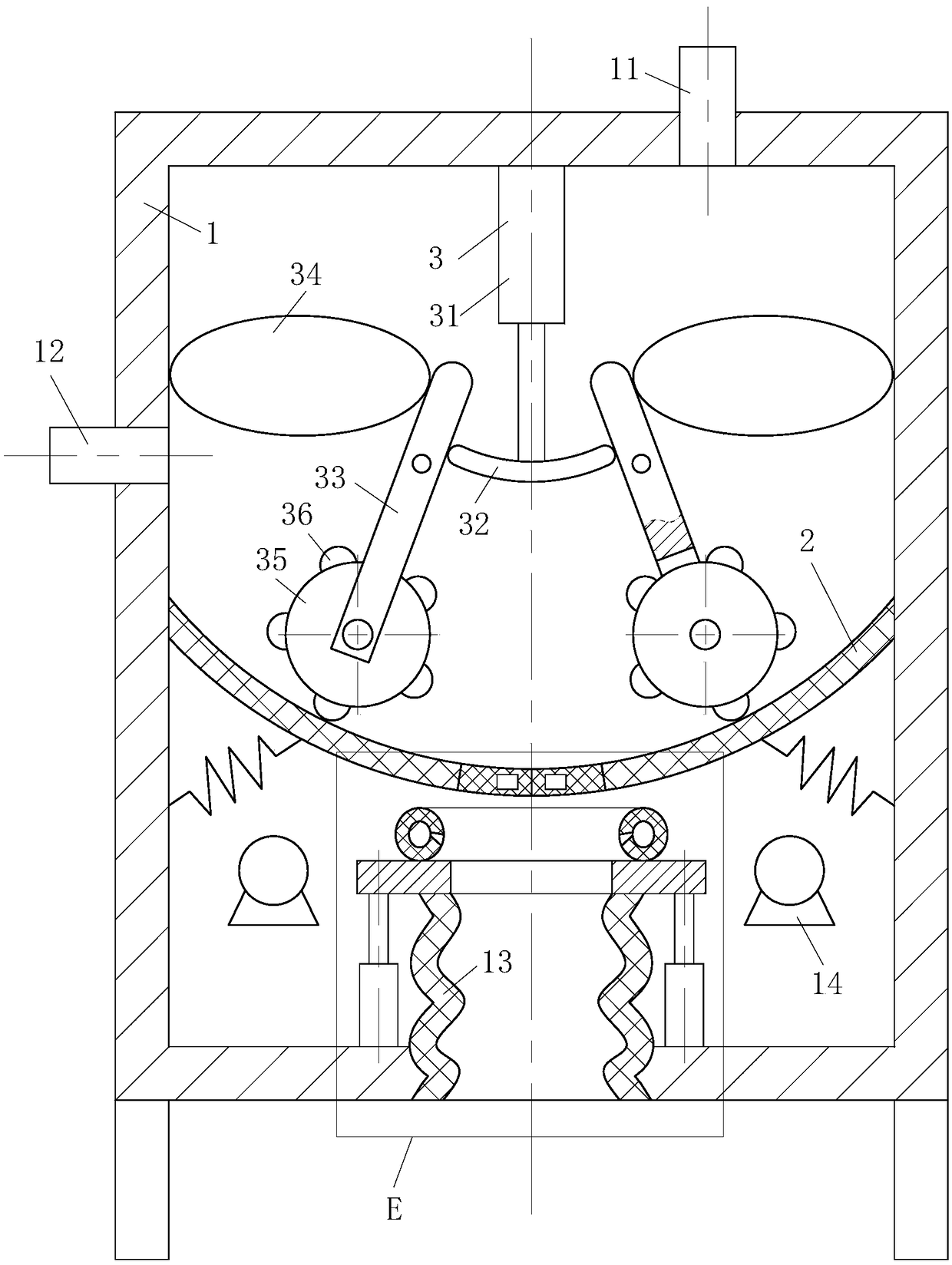

[0023] As an embodiment of the present invention, the pushing plate 32 is arranged in a downwardly convex arc shape, and the pushing plate 32 is made of elastic material. As the pushing plate 32 moves upward, when the pushing plate 32 is separated from the stirring plate 33, the stirring plate 33 can also shake periodically under the inertia of the stirring roller 35, which is convenient for energy saving.

[0024] As an embodiment of the present invention, the bottom of the supporting airbag 34 is provided with an air extraction pipe, and a corresponding one-way valve is provided on the air extraction pipe. Corresponding one-way valves are provided. Under the action of periodic contraction of the supporting airbag 34, the water vapor in the box body 1 is drawn away, and the water vapor can be used as a heat source for secondary utilization, thereby saving energy.

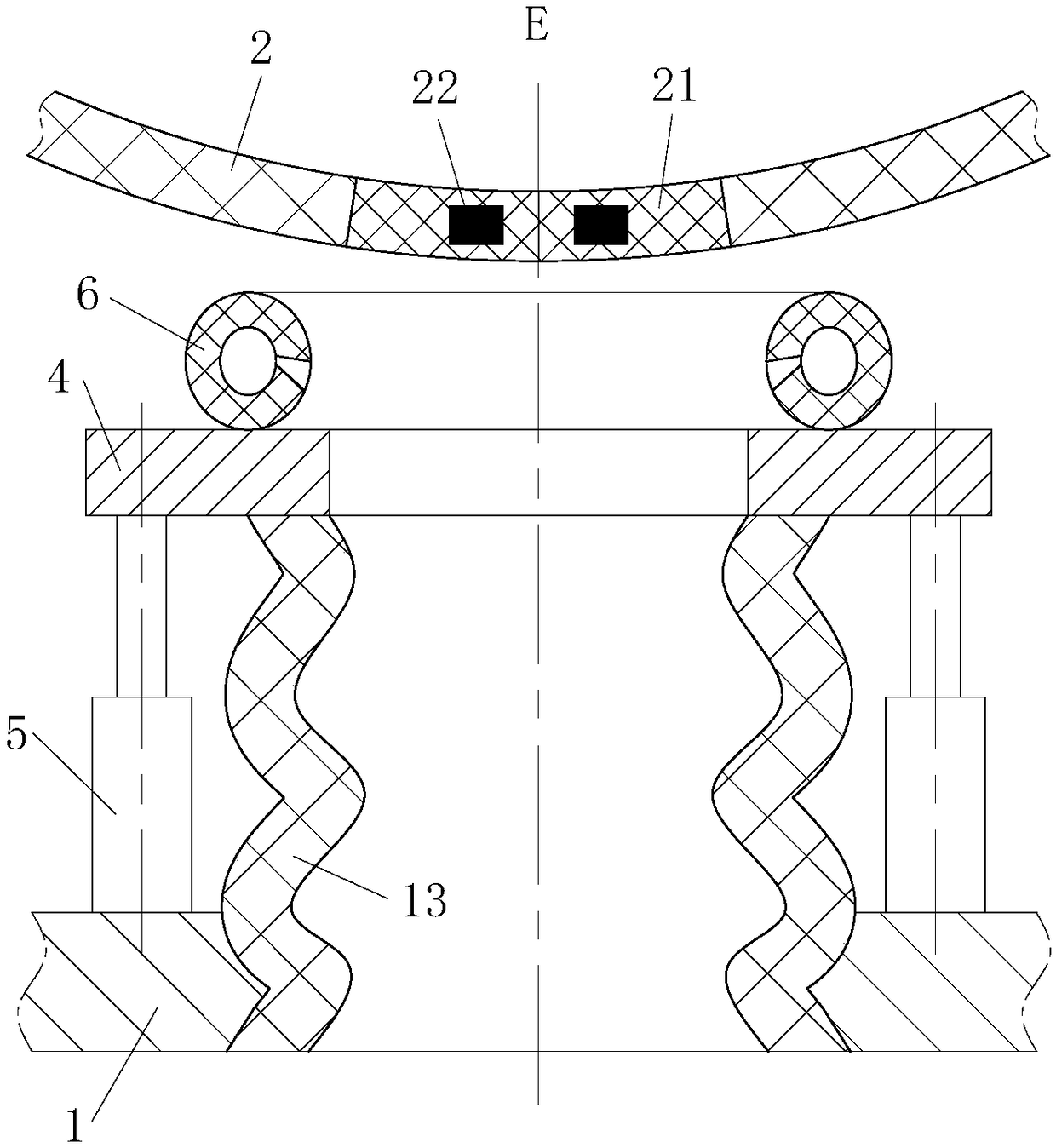

[0025] As an embodiment of the present invention, an electromagnet 22 is provided inside the sealing rubber strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com