Automatic medium adding system for dense medium density separation in coal preparation plant, and working method

A density sorting and working method technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as inconvenient operation, large amount of raw coal selection, high labor intensity of processing, etc., to improve work efficiency , saving manpower and avoiding the effect of abnormal sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and through the examples. The following examples are to explain the present invention and the present invention is not limited to the following examples.

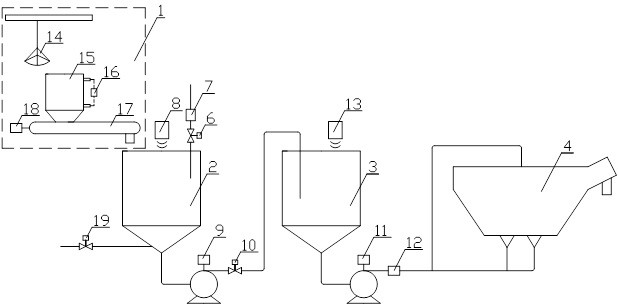

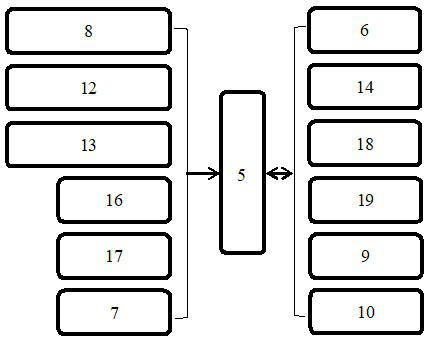

[0018] see Figure 1 to Figure 2 , a system for automatic medium density separation of dense medium in coal preparation plant, including feeding device 1, thick medium barrel 2, qualified medium barrel 3, heavy medium sorting device 4 and controller 5, feeding device 1, thick medium barrel 2 The medium barrel 2, the qualified medium barrel 3, and the heavy medium sorting device 4 are connected in sequence. The top of the concentrated medium barrel 2 is installed with a water supplement pipe, and the supplement water pipe is installed with a water supplement control valve 6 and a water supplement flow meter 7, and the top of the thick medium barrel 2 is installed. There is also a concentration tank liquid leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com