Production equipment and technique for dustproof mesh

A technology for production equipment and dust-proof nets, applied in the field of dust-proof nets, can solve problems such as low production efficiency, time-consuming and labor-consuming quality control, and achieve the effects of labor saving, high degree of automation and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

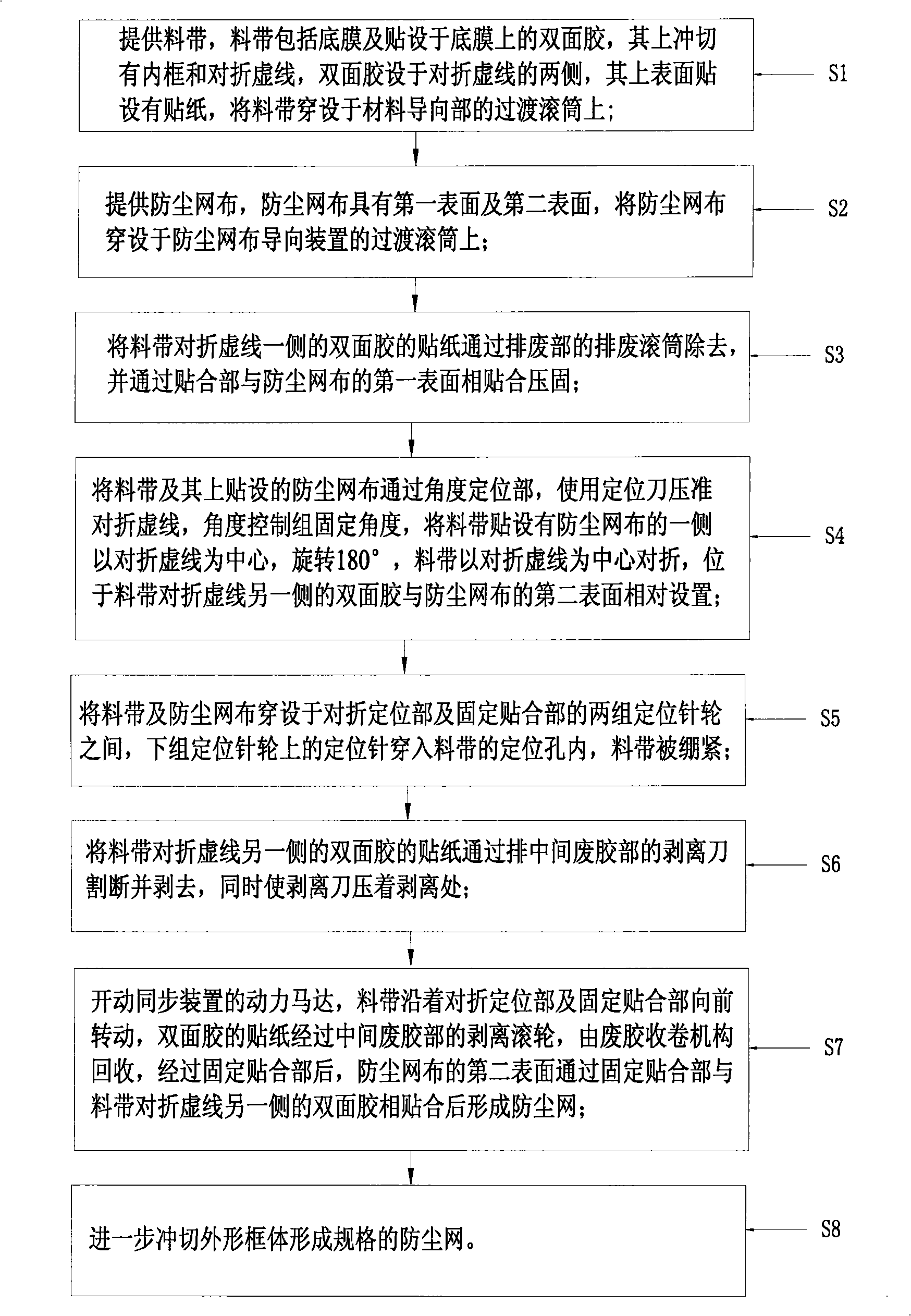

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] The production equipment of the dust-proof net of the present invention is used to produce the dust-proof net, and the dust-proof net comprises: two layers of bottom film, a dust-proof mesh cloth arranged in the middle of the bottom film, and the dust-proof mesh cloth has a first surface and a second surface , respectively bonded to the two layers of bottom film by means of double-sided adhesive tape. There are stickers on the surface.

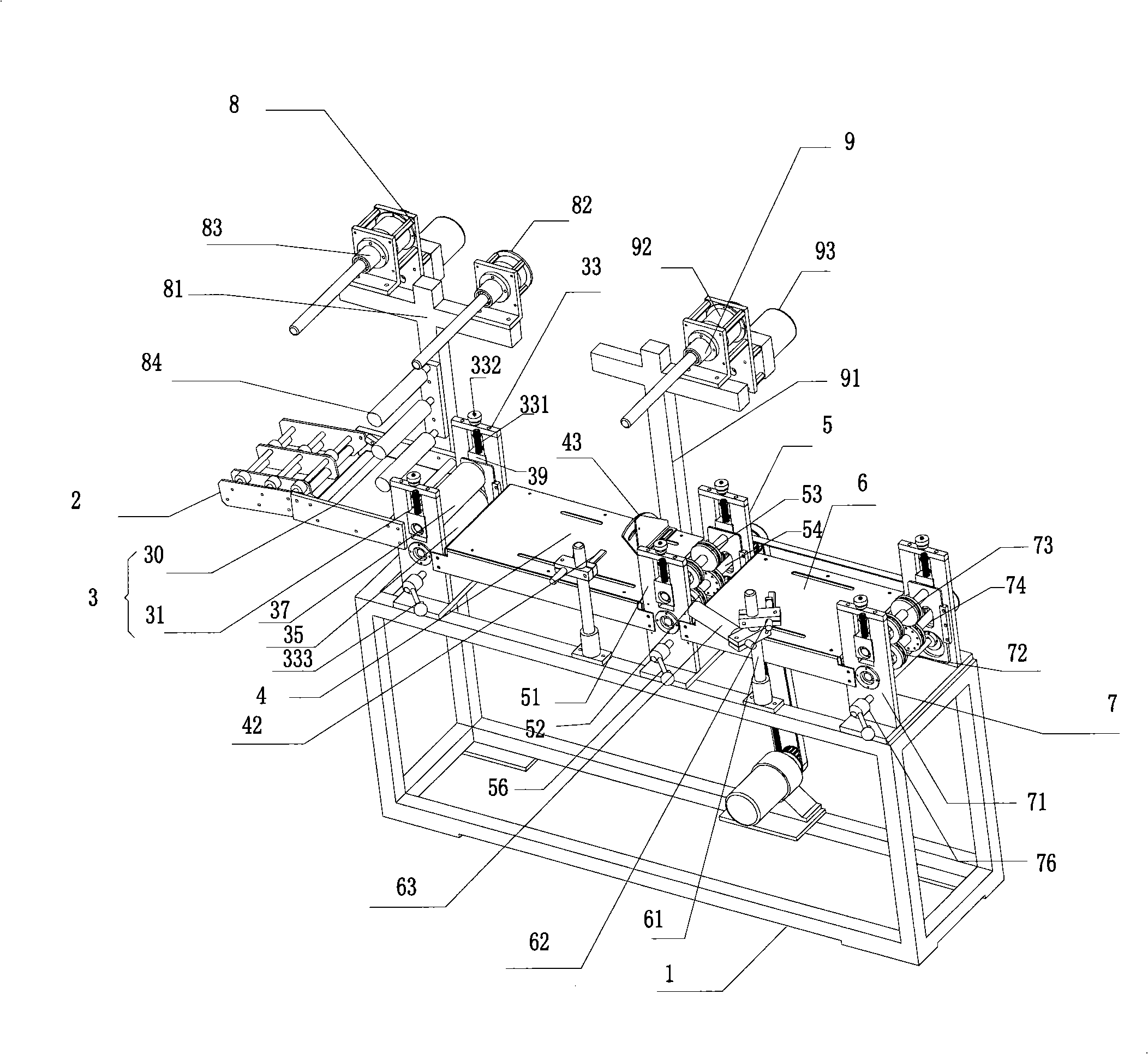

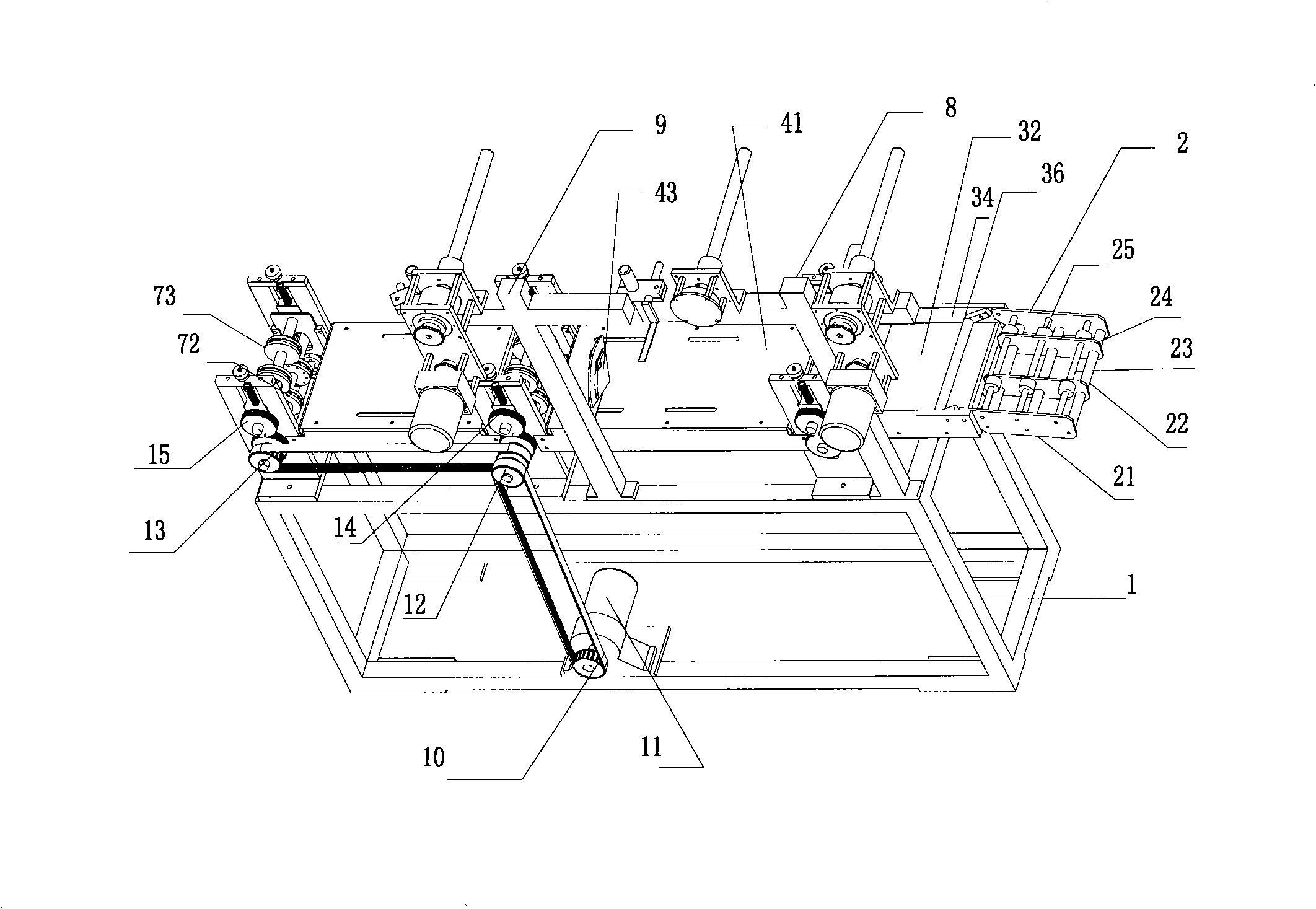

[0023] Such as Figure 1-2 As shown, the production equipment of the dust-proof net of the present invention includes: a frame 1, a material guide part 2 sequentially arranged on the frame 1, a waste discharge fitting part 3, an angle shaping part 4, a half-fold positioning part 5, and a middle waste row. The glue part 6 and the fixed fitting part 7; the waste discharge fitting part 3 includes a waste discharge part 30 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com