Automatic desulfurization system and method for sintering flue gas

A desulfurization system and technology of sintering flue gas, which is applied in the field of sintering flue gas desulfurization, can solve the problems of large environmental impact of differential pressure guide pipes and inaccurate measurement, and achieve the goals of reducing energy consumption, preventing pollutant discharge, and improving desulfurization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] 1. Realization of desulfurization automatic water supply control

[0024] The water supply system is a very important system for flue gas desulfurization. In the desulfurization process, the lime is digested to produce substances that chemically react with the sintering flue gas to purify the flue gas. In practical application, the water volume is adjusted manually, and the required water volume cannot be accurately judged, which affects the flue gas purification effect. To solve the problems mentioned above, an automatic water supply control system was invented.

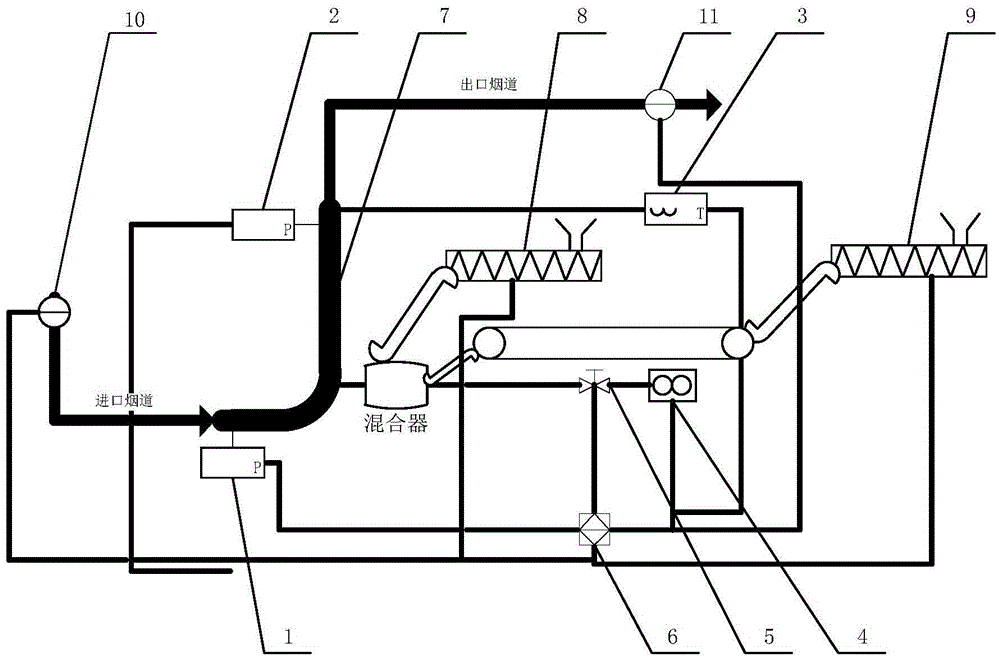

[0025] (1) Install pressure transmitters at the inlet A and outlet B of the reactor respectively to ensure that the pressure-taking pipeline is located near the pipeline. Then the pressure data is transmitted to the PLC system through the cable. Set P A is the actual measured pressure at A, P B is the actual measured pressure at B, and X is the pressure difference before and after the reactor, then the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com