Insulation board horizontal cutting device

A technology for horizontal cutting and insulation boards, applied in stone processing tools, manufacturing tools, stone processing equipment, etc., to achieve automatic production and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

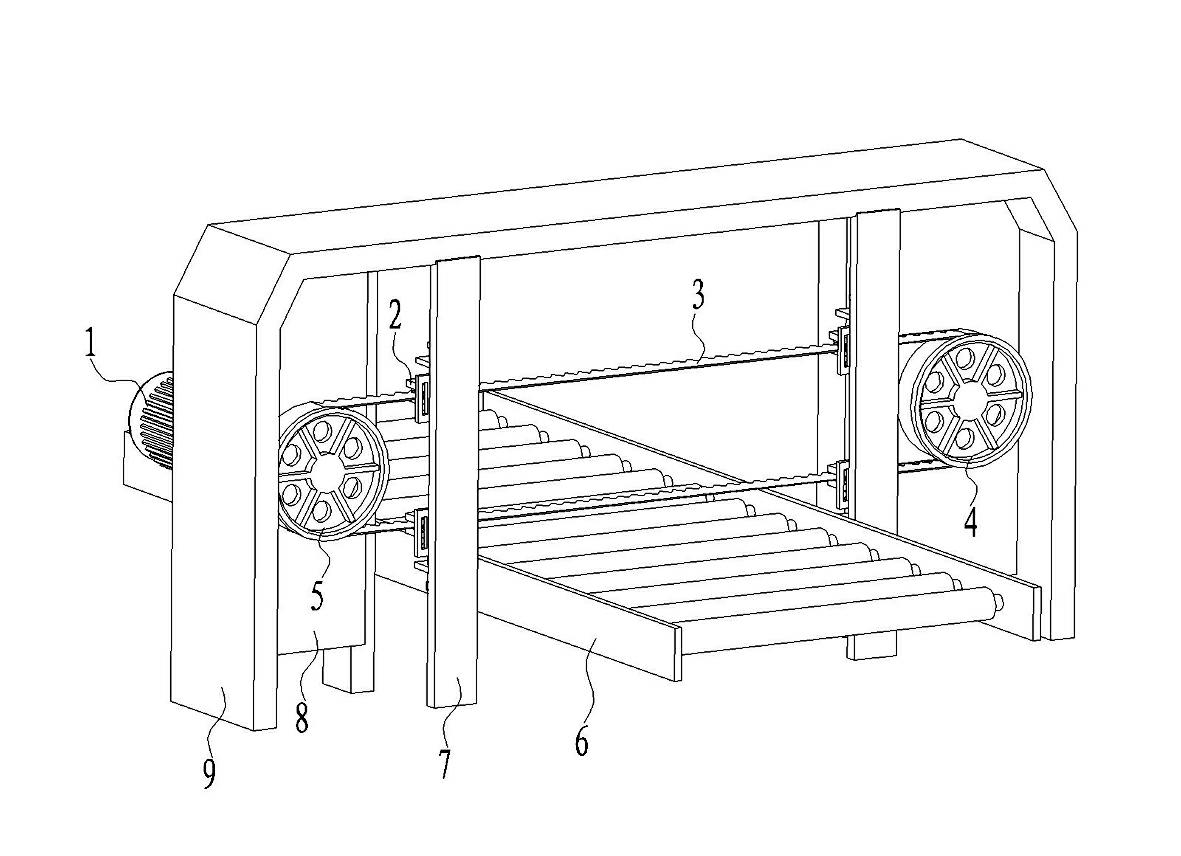

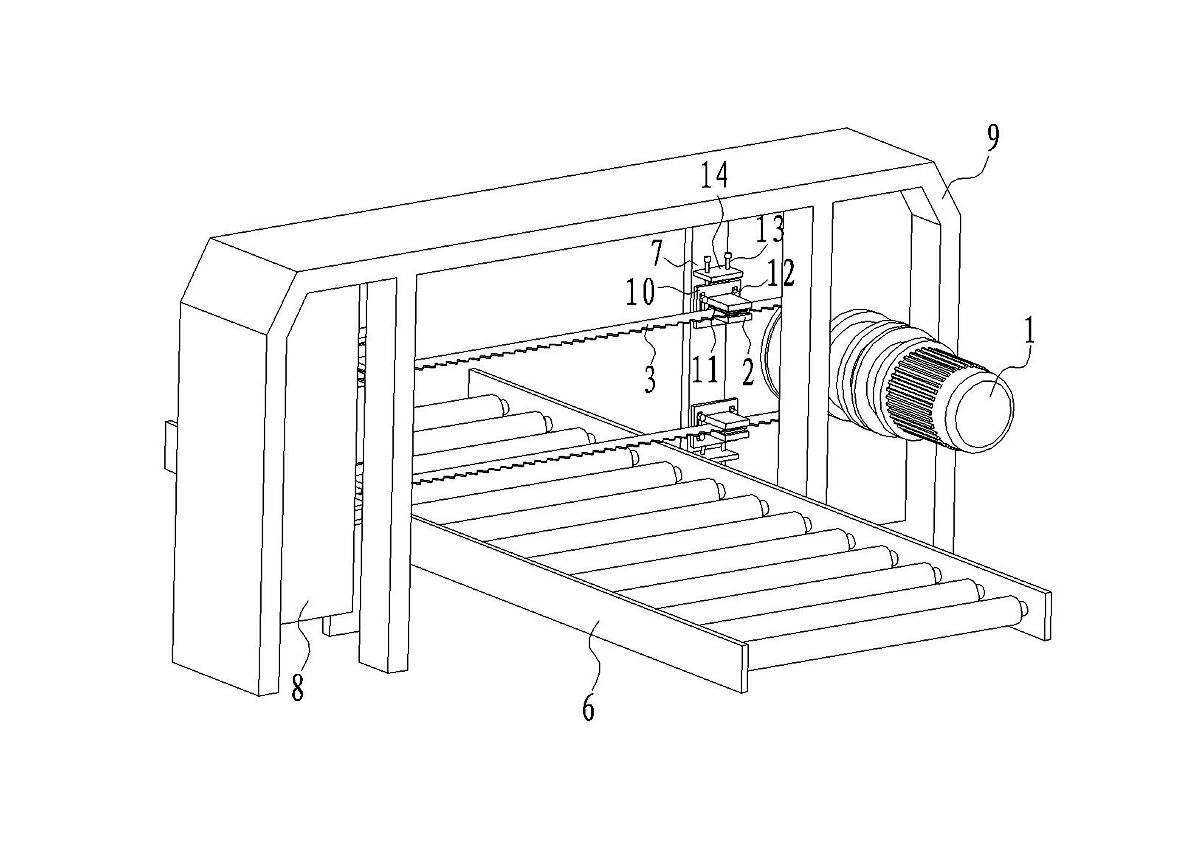

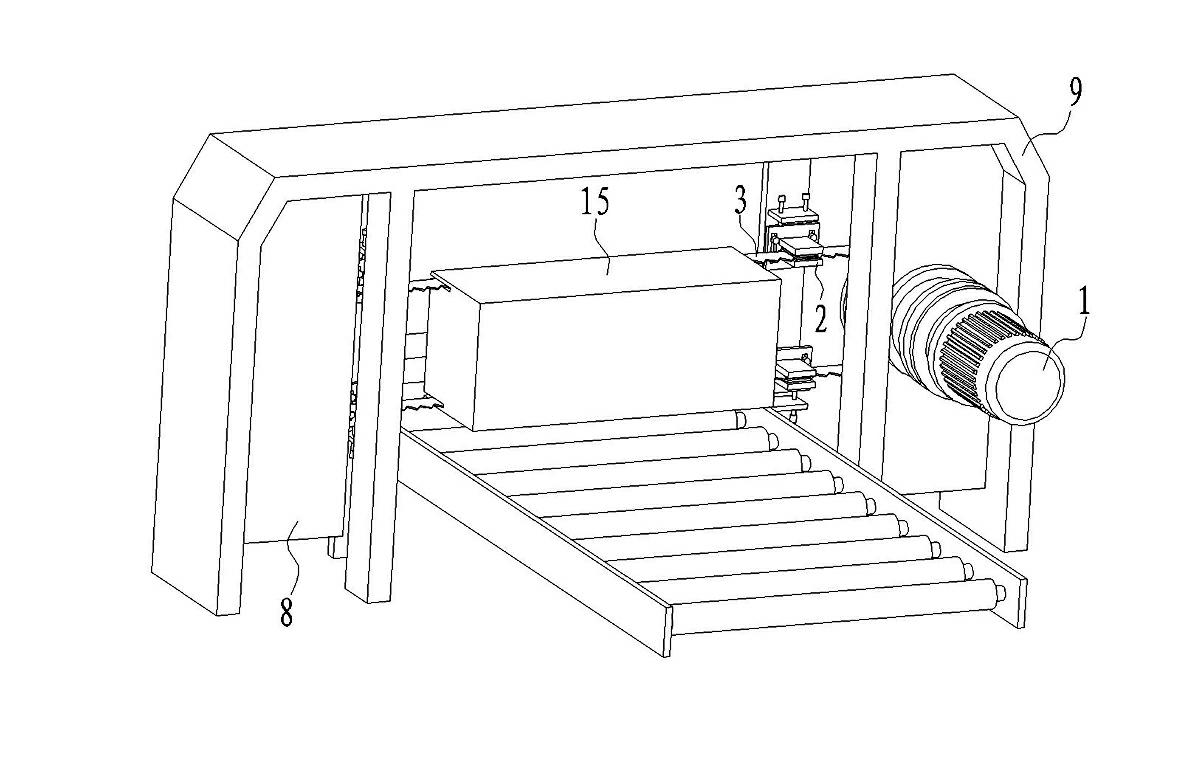

[0020] Such as figure 1 and figure 2 As shown, the thermal insulation board horizontal cutting device of the present invention includes a horizontal conveying device for transporting the thermal insulation board, and also includes a frame 9, the frame 9 is preferably spanned from the left side of the conveying device 6 to the right side of the conveying device 6, at The frame 9 on the left and right sides of the conveying device 6 is respectively provided with a horizontal vertical vertical plate 8, and the same side of the two vertical plates 8 is respectively provided with a driving pulley 5 and a driven pulley 4, and the two pulleys The horizontal heights of the pulleys are equal, and the two pulleys are connected by a band saw 3 that spans the conveying device 6. The band saw 3 forms an upper and lower ring-shaped closed structure around the two pulleys. The band saw 3 follows the active Belt pulley 5 rotates synchronously, and described drive belt pulley 5 is also provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com