Method for preparing nanometer high-strength copper flat wire through pulling-up, continuous ECAP, and drawing processes

A high-strength, copper flat wire technology, applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as energy waste and reduce enterprise production efficiency, and achieve the effects of reducing energy waste, improving production efficiency, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

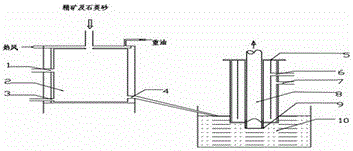

[0021] (1) Smelting process: wash and clean the copper ore, pre-dry it, and then figure 1 As shown, smelting and refining are carried out to obtain a copper solution, and then configured according to the content of Mg: 2.5%-3.3% and the balance is Cu to obtain the required copper solution. Preparation of copper rod blanks by uplink method: the copper melt obtained in step (1) is passed through Figure 1 The middle melt outlet 4 is introduced into the molten pool 10, and a standard graphite mold is selected to prepare a copper rod blank with a circular cross-sectional diameter of 17.15 mm.

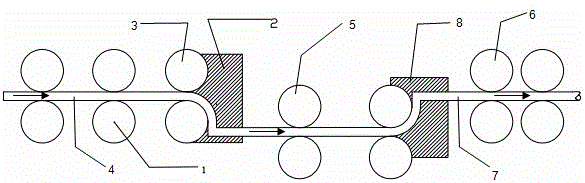

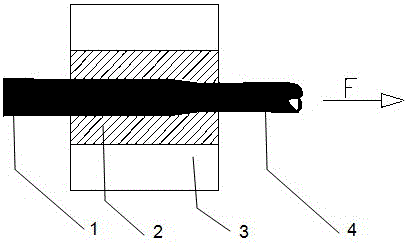

[0022] (2) Continuous ECAP extrusion process to prepare nano high-strength copper flat wire: use the copper rod blank with a circular cross-section diameter of 17.15mm prepared in step (1) to use a copper wire continuous rolling mill, and use roller friction as the driving force , so that the billet enters the continuous ECAP extrusion process, and its die is as figure 2 As shown in midd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com