Automatic breaker production line and work method thereof

A technology of automatic production line and circuit breaker, applied in the field of machinery, can solve the problems of low efficiency, difficult to trace the cause, prone to errors, etc., to achieve the effect of improving production efficiency, improving resource utilization, and reducing defective product rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

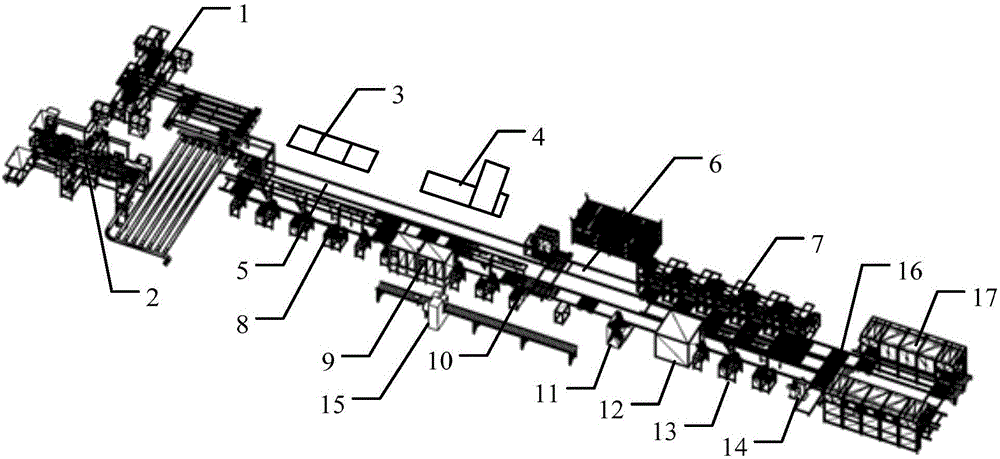

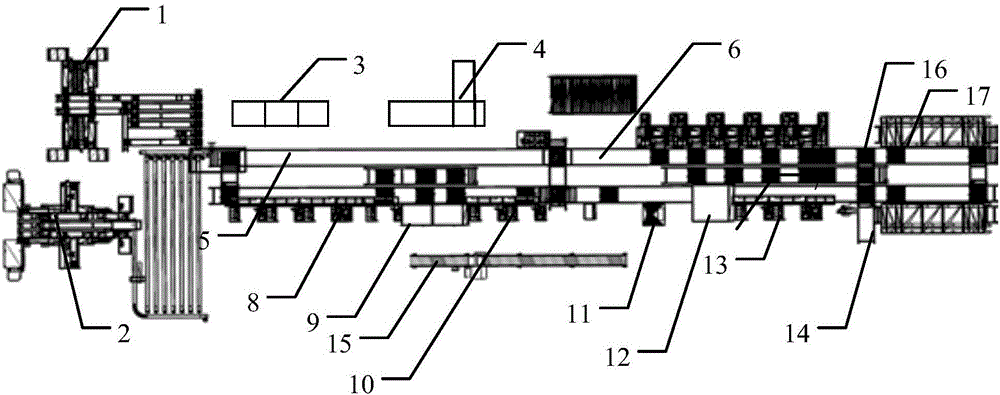

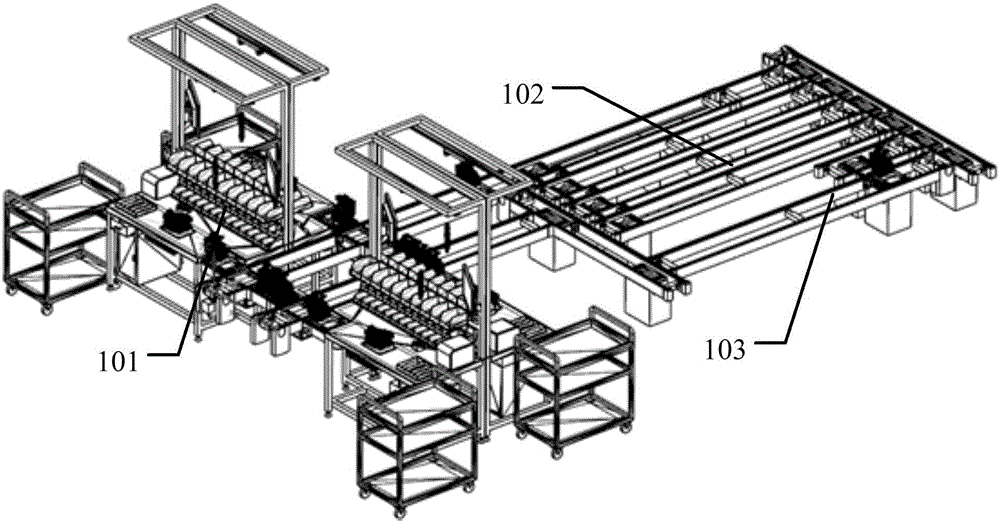

[0079] The invention discloses an automatic circuit breaker production line and its working method. By combining an operating mechanism, a terminal box assembly mechanism, a BCB storage mechanism, an energy storage spring assembly mechanism, a BCB batching mechanism, an accessory batching mechanism, an accessory assembly mechanism, and a BCB assembly Mechanism, running-in mechanism, arc chute installation mechanism, full inspection mechanism, visual inspection mechanism, panel assembly mechanism, laser marking machine, packaging line, visual inspection station mechanism and comprehensive test bench are integrated and controlled in the same way, which can realize circuit breaking automatic production of devices.

[0080] The technical solutions in the embodiments of the present invention will be described clearly and in detail below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com