Equipment used for producing spring ring

A technology of spring coils and spring coil sheets, which is applied in the field of equipment for producing spring coils, can solve the problems of low degree of automation and intelligence, difficulty in meeting large-scale production, etc., and achieve the effect of ensuring intelligence and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will be combined with Figures 1 to 11 The present invention is further described, but it should not be used to limit the protection scope of the present invention. For the convenience of description and understanding of the technical solution of the present invention, the orientation words used in the following description are all subject to the orientation shown in the drawings.

[0027] The invention is a device for producing spring coils, which can directly and automatically produce spring coils from steel sheet raw materials, realizing full automation and intelligence. Of course, in the technical solution, it is not limited to the production of spring coils.

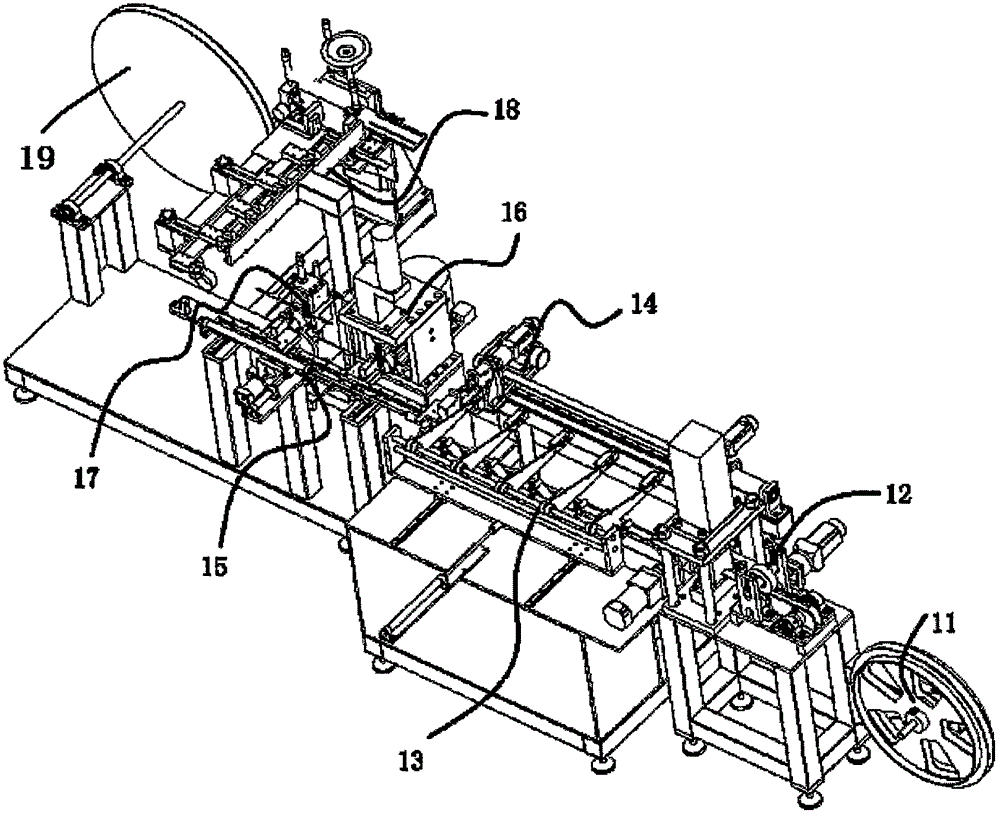

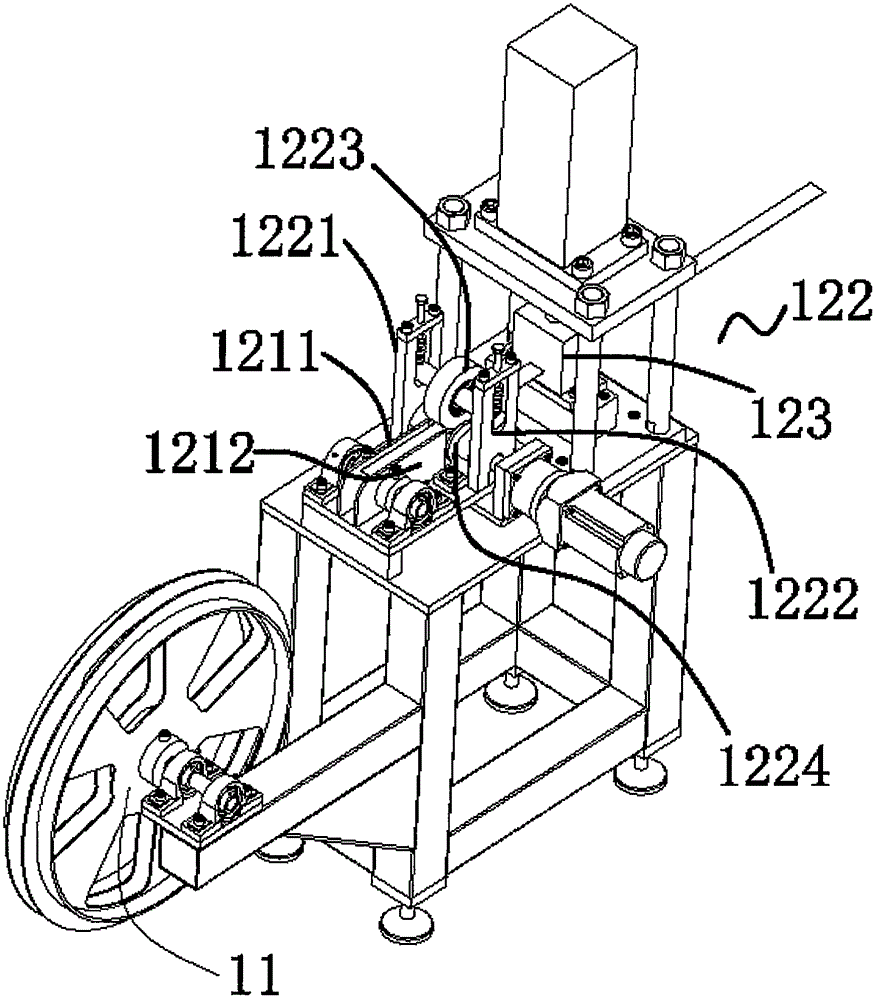

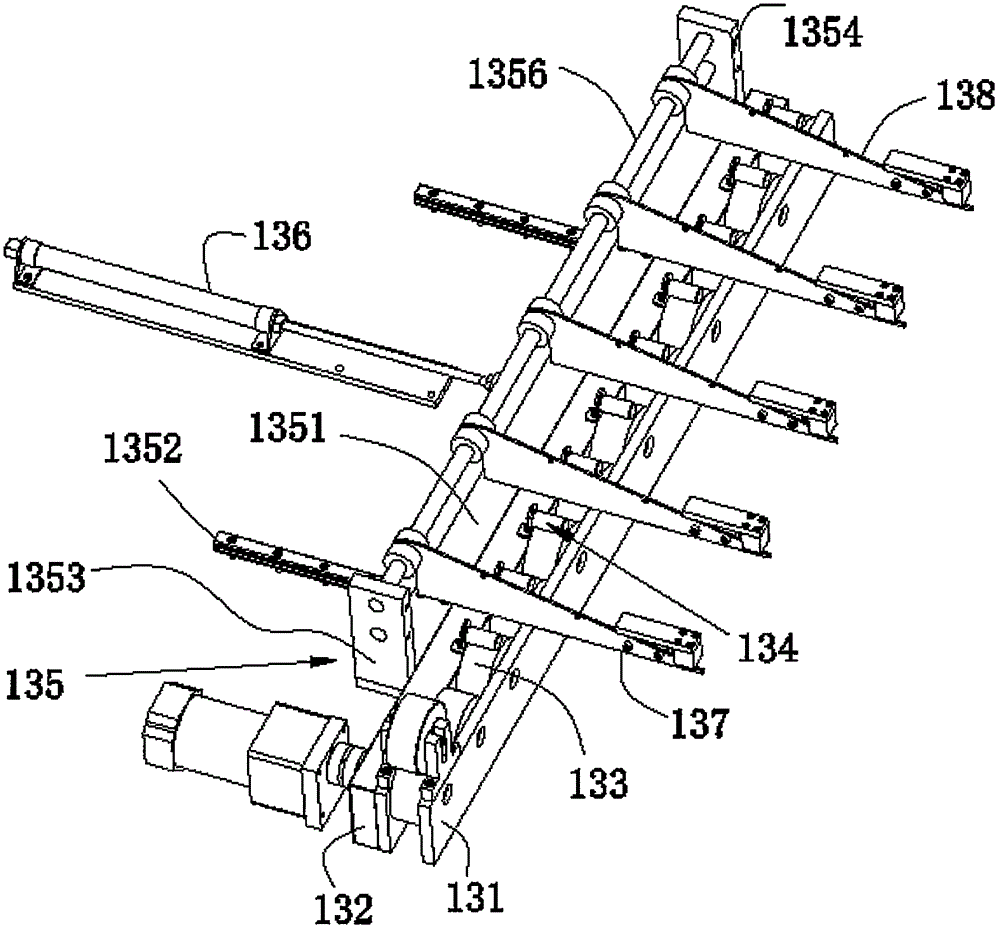

[0028] see figure 1 . In this embodiment, a device for producing spring coils includes a feeding mechanism 11, a guide cutting mechanism 12, a first clamping mechanism 13, a crimping mechanism 14, a second clamping mechanism 15, a riveting mechanism 16, and a gluing mechanism 17 and upper cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com