Automatic painting production line capable of recycling excess paint

An assembly line and automatic technology, applied in the coating, the device for coating liquid on the surface, the surface pretreatment, etc., can solve the problems of low production efficiency, environmental pollution, and non-compliance with environmental protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

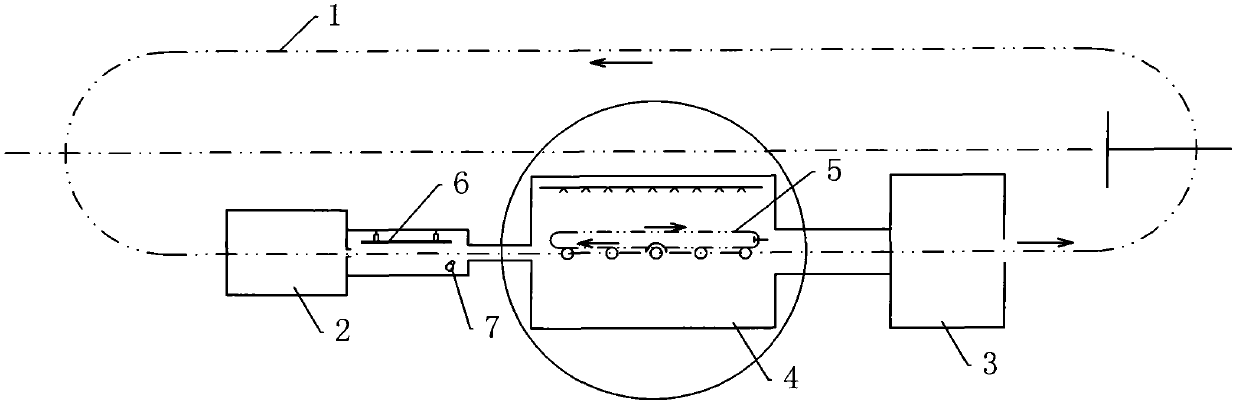

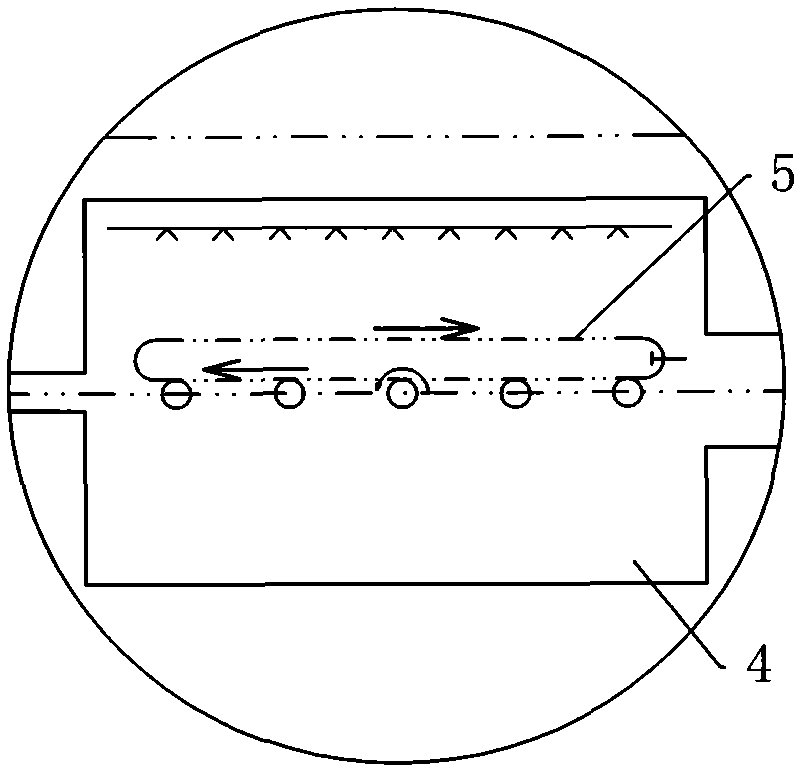

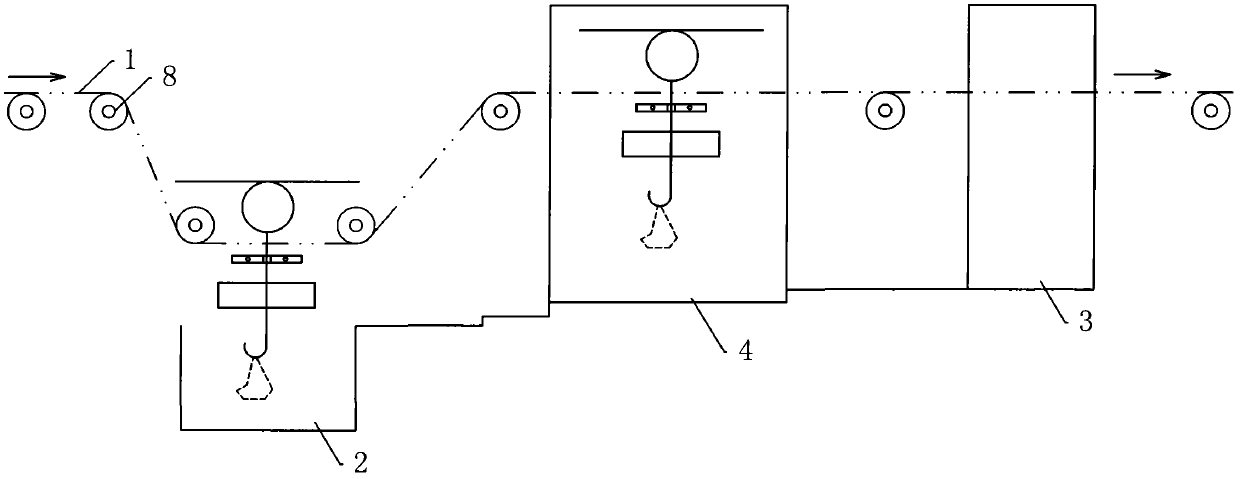

[0025] Embodiment one: if Figure 1 to Figure 7 As shown, the automatic painting line that can recover residual paint includes a closed loop main conveying chain 1, and the main conveying chain 1 is dynamically connected with a main chain driving device, and the main chain driving device is a speed-regulating motor. A rotatable workpiece holding device is installed on the chain 1. The workpiece holding device includes a suspender 10 installed on the main conveying chain. The lower end of the suspender 10 is rotatably connected with a workpiece 16 suspension hook 11. A centrifugal runner 12 is fixed on the hook 11, and a rotating guide wheel 13 is also rotatably installed on the hook 11; along the running direction of the main conveying chain, a paint dipping device, a residual paint recovery device and a drying device are sequentially arranged. Drying chamber 3, the drying chamber 3 is provided with a heating device, the paint dipping device includes a paint dipping tank 2 loc...

Embodiment 2

[0031] Embodiment two: if Figure 8 As shown, the structure of Embodiment 2 and Embodiment 1 is basically the same, the only difference is that the centrifugal drive chain 5 in the workpiece rotation drive device is replaced by a conveyor belt, and correspondingly, the centrifugal runner 12 on the workpiece holding device is The line-paying friction wheel is used. When working, the line-paying friction wheel cooperates with the conveyor belt to drive the workpiece to rotate and realize the function of paint rejection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com