Potato cleaning machine

A technology for cleaning machinery and potatoes, applied in applications, food processing, food science, etc., can solve problems such as poor effect, high cleaning efficiency, and reduced production efficiency, and achieve the effects of easy subsequent cleaning, efficient removal, and improved scrubbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

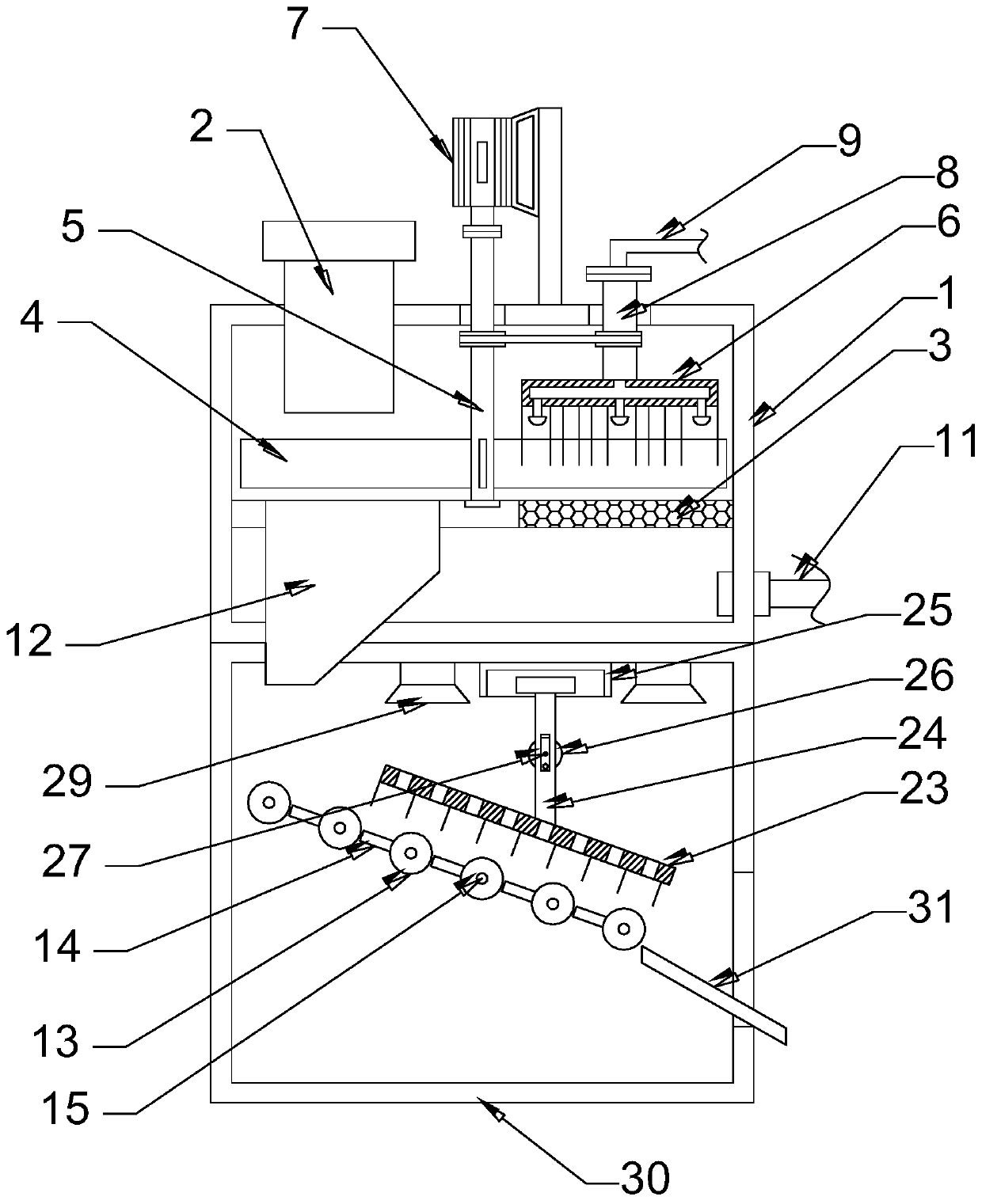

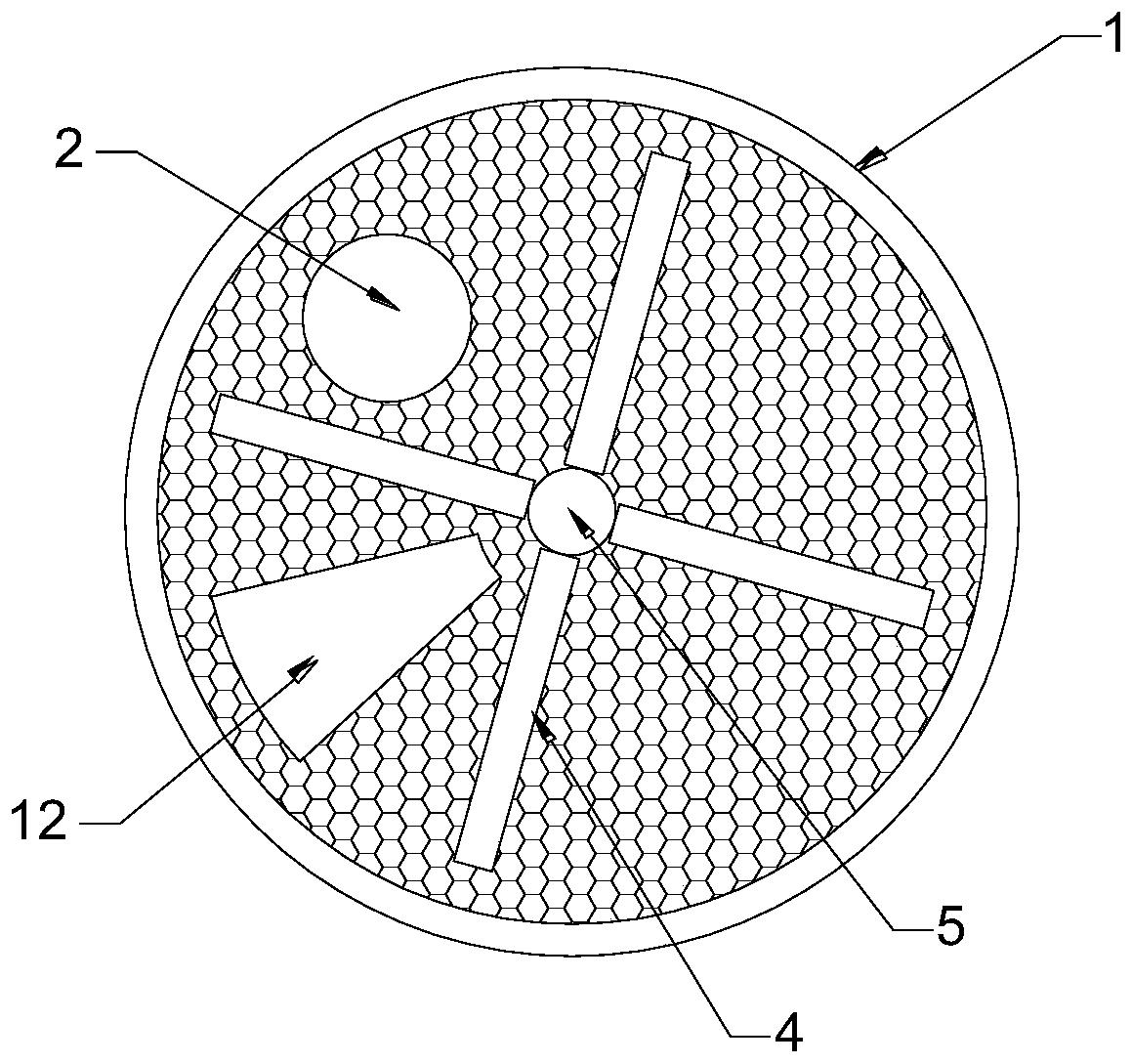

[0023] see Figure 1-6 , in an embodiment of the present invention, a kind of potato cleaning machine, comprises mud removal box 1; Said mud removal box is nested with load-bearing network disk 3, and through hole is evenly distributed on the load-bearing network disk 3; Said load-bearing network disk 3 Push plate 4 is abutted on the top and is distributed in a circle, and push plate 4 is fixedly connected with central shaft 5, and central shaft 5 extends to the top of mud removal box 1 and is connected with a first drive motor 7 through a coupling, and the first drive motor 7 Drive the push plate 4 to rotate, and then push the potatoes to move on the carrying network disk 3; the upper end of the mud removal box 1 is connected with a feed pipe 2, and the potatoes are dropped into the mud removal box 1 from the feed pipe 2; A feeding pipe 12 is nested on the disk 3, and the feeding pipe 12 and the feeding pipe 2 are arranged in a staggered manner.

[0024] A scrubbing tray 6 i...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is: the fine cleaning box 30 is fixedly connected to the lower end of the mud removal box 1, and the feeding pipe 12 extends into the fine cleaning box 30; The feeding roller 13, the feeding roller 13 is fixedly connected with a rotating plate 14, the feeding roller 13 is rotatably connected with the fine cleaning box 30 through the rotating shaft 15; the rotating shaft 15 extends to the outside of the fine cleaning box 30 and is fixedly connected with a rolling gear 16 , the rolling gear 16 is toothed with a rack plate 17, the rack plate 17 is fixedly connected with the first moving frame 18, the first moving frame 18 is connected with the first eccentric disc 20, the first moving frame 18 is provided with a rectangular groove, and the rectangular groove An eccentric column is nested inside, and the eccentric column is fixedly connected with a first eccentric disk 20, and the first eccentric disk 20 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com