Circulating dredging type industrial wastewater treatment device and using method thereof

A technology for treating equipment and industrial wastewater, which is applied in multi-stage water treatment, water/sewage treatment, multi-stage water/sewage treatment, etc. It can solve the problems that waste residue cannot be cleaned at one time, affects wastewater treatment operation, and poor filtering effect of the device. , to achieve the effects of protecting joint health, dredging pipes, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

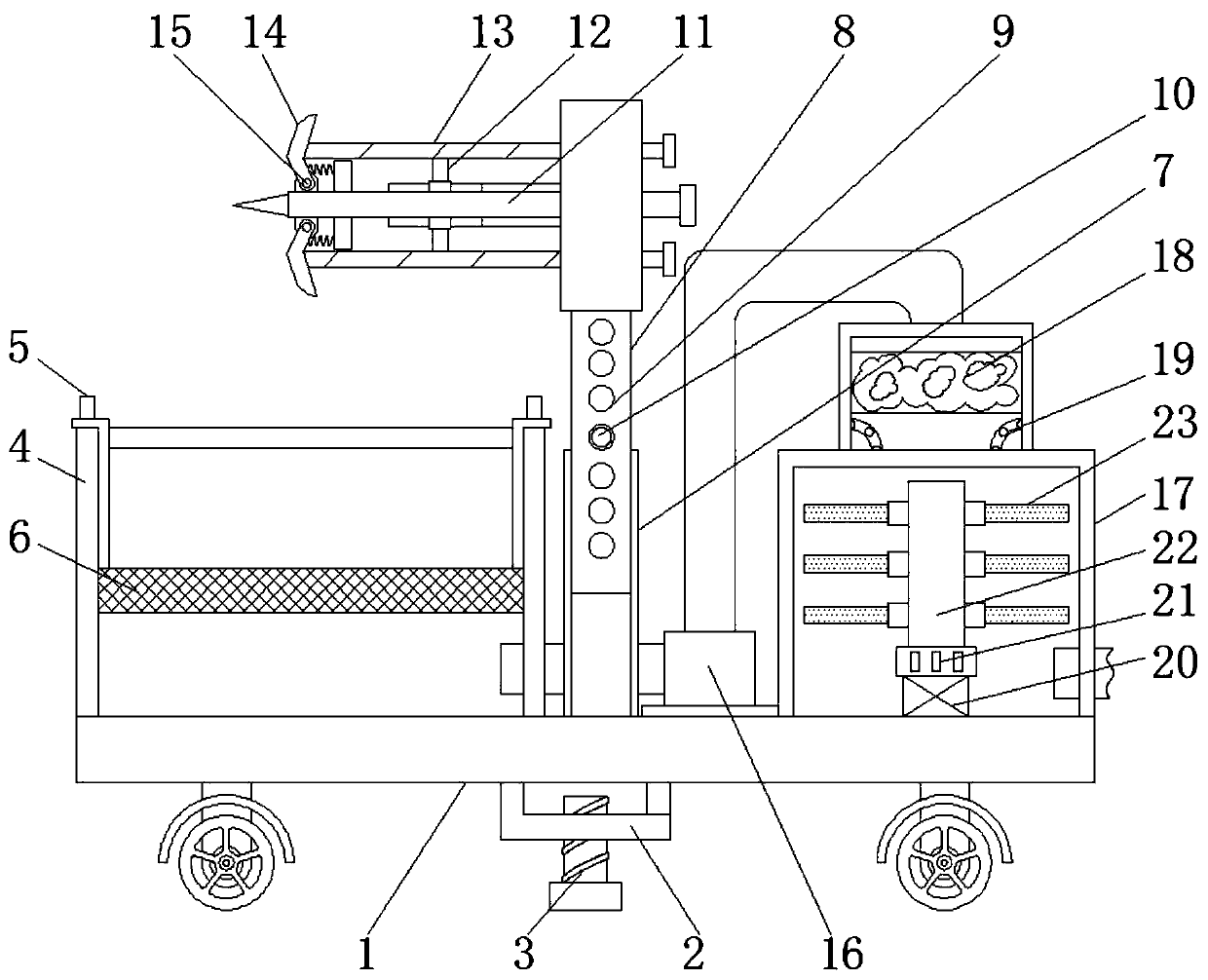

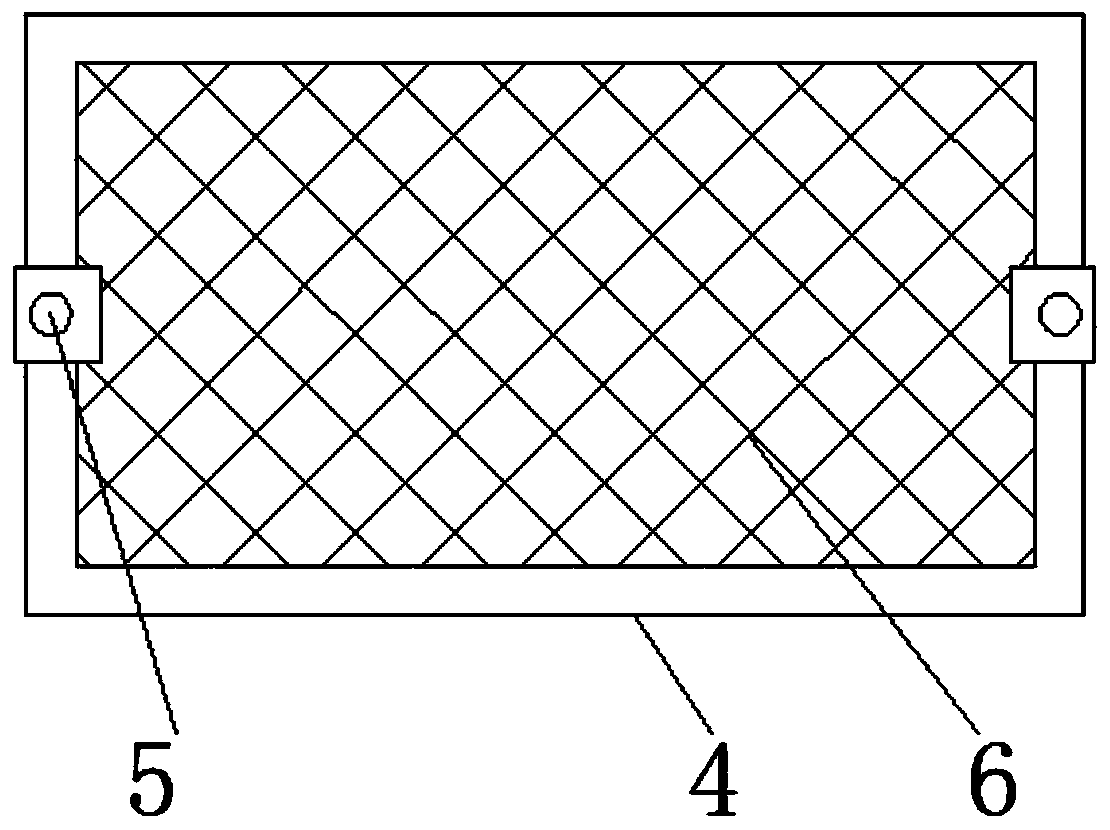

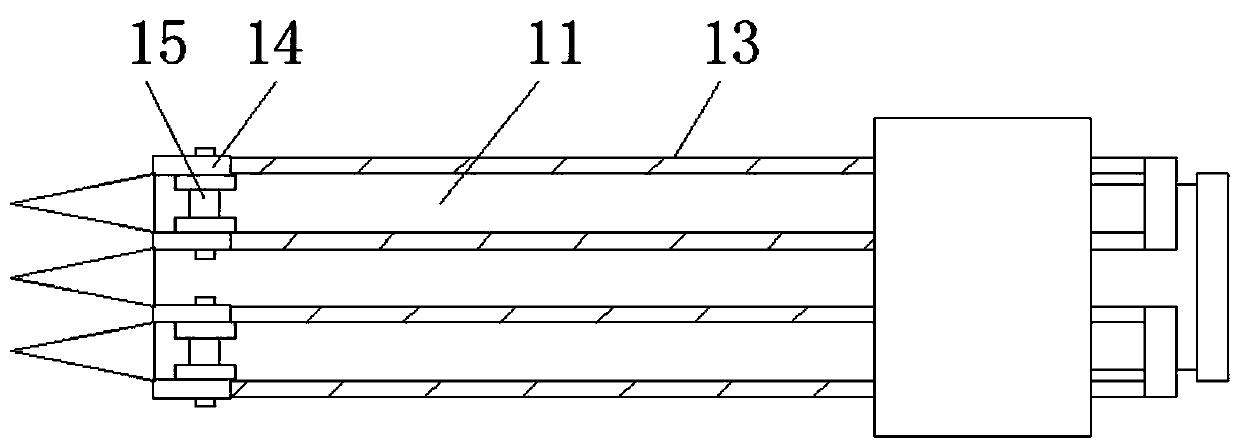

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 It is a schematic diagram of the front section structure; figure 2 It is a schematic diagram of the structure of the filter net; image 3It is a schematic diagram of the top view structure of the drill block. A circulating and dredging industrial wastewater treatment device includes: a mobile base 1, a fixed block 2, a threaded rod 3, a waste residue box 4, a fixed column 5, a filter screen 6, an outer cylinder 7, an inner rod 8, a notch 9, and a clamping rod 10 , drill bit 11, slide block 12, pull rod 13, scraper block 14, rotating shaft 15, water pump 16, filter bucket 17, filter cotton 18, pulley 19, motor 20, bearing 21, stirring rod 22 and activated carbon rod 23, described mobile base A fixed block 2 is fixed at the lower middle position of 1, and a threaded rod 3 runs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com