Polyurethane multifunctional high-pressure mixing head device

A high-pressure mixing and polyurethane technology, which is applied in the field of polyurethane multifunctional high-pressure mixing head device, can solve the problems that the pressure of polyurethane raw materials cannot be accurately controlled, polyurethane cannot be fully atomized, and the mixing effect is not good, so as to achieve reasonable structure and high mixing efficiency , the effect of uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

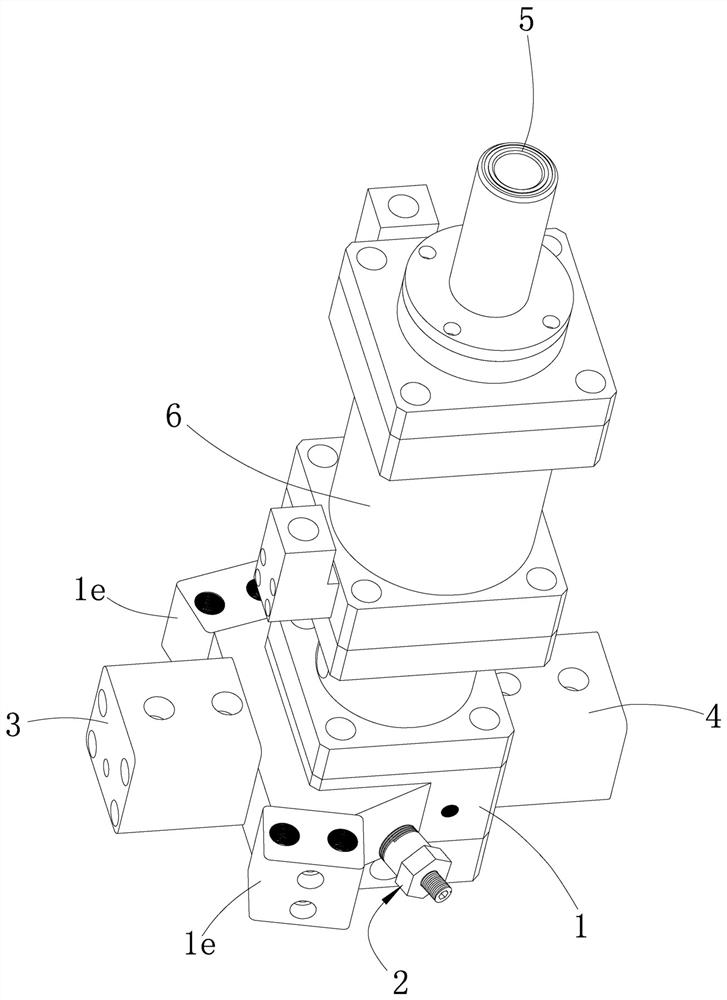

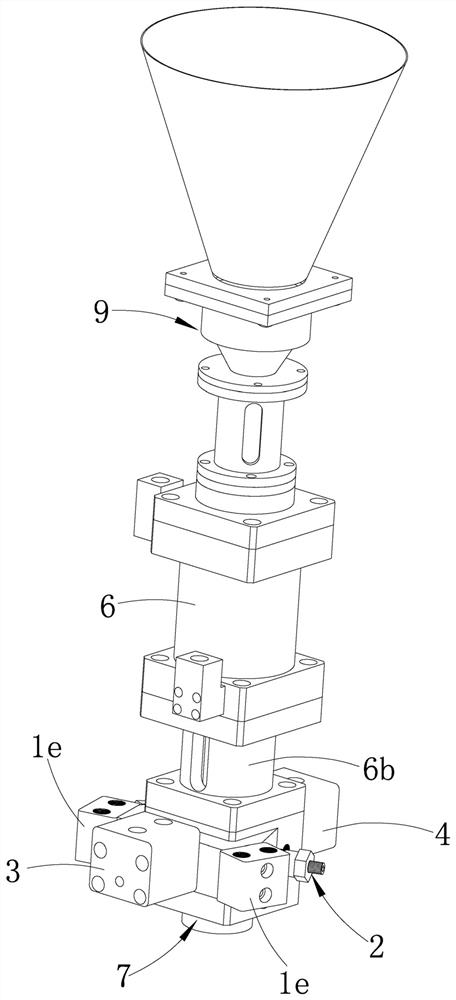

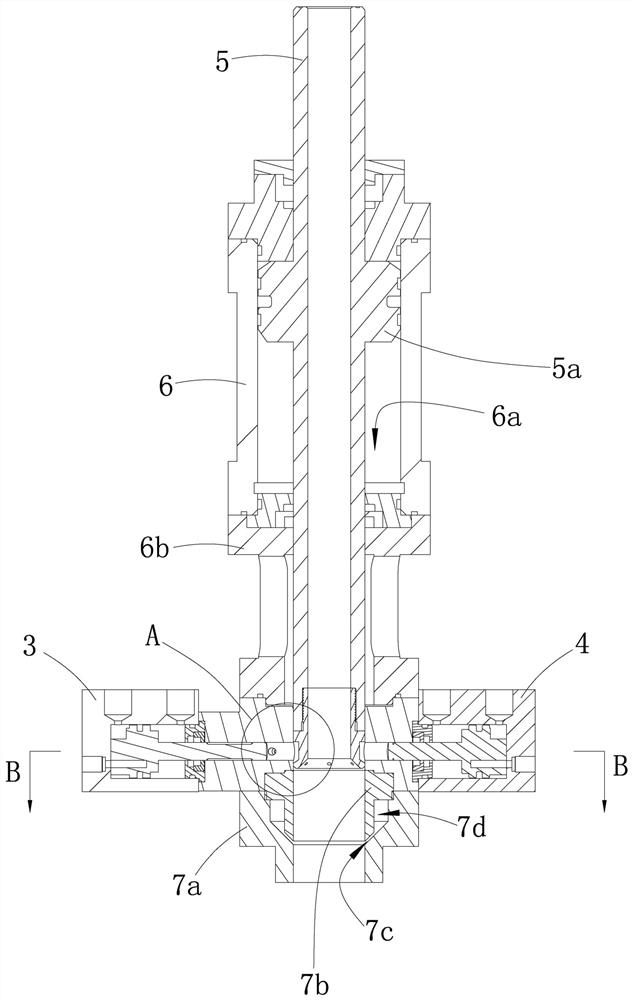

[0040] Such as Figures 1 to 10 shown

[0041] The mixing head device includes a feeding pipe 5 , a main mixing seat 1 , an auxiliary mixing seat 7 , a spraying control assembly, a cleaning control assembly, two material pressure regulating valves 2 , a mixing core 8 and a telescopic cylinder 6 .

[0042]The main mixing seat 1 also has an inner hole that runs through its upper and lower end faces. The bottom of the inner hole of the main mixing seat 1 is provided with an outlet. The side wall of the main mixing seat 1 has a horizontal main feeding through hole 1b, and the main feeding through hole 1b extends On the inner wall of the main mixing seat 1, there are two groups of material holes in the main mixing seat 1, which correspond to the two material pressure regulating valves 2 one by one, and the two groups of material holes are horizontally distributed in the main feeding through hole 1b On both sides, each group of feed holes includes an independent feed hole 1c and di...

Embodiment 2

[0061] The difference between the present embodiment and the first embodiment is only that the mixing core is not included in the present embodiment, and the inlet of the auxiliary mixing seat of the mixing head device is not communicated with high-pressure air, but other powders (such as gypsum powder, etc.), Feed pipe 5 is loaded onto silk plug then and uses as common conventional " L " type mixing head. It can produce soft foam sponge; hard foam imitation wood; semi-rigid foam insulation board pipes, etc., which greatly expands the applicable environment of this mixing head device and meets the processing needs of different materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com