A kind of advancing and retreating mold device for oil seal forming machine

A molding machine, advancing and retreating mold technology, applied in the field of oil seal processing, can solve the problems of inconvenient removal of oil seals, inconvenient height adjustment, and reduced processing efficiency, and achieve the effects of improving processing efficiency, shortening molding time, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

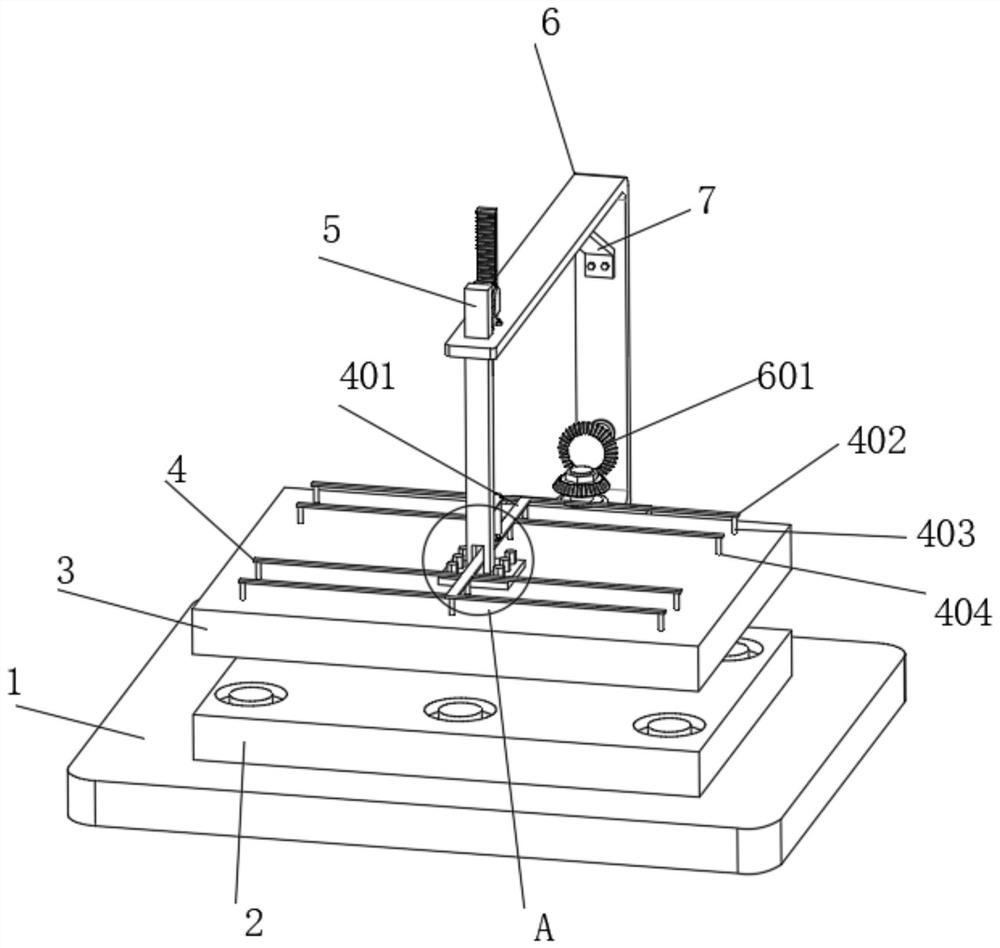

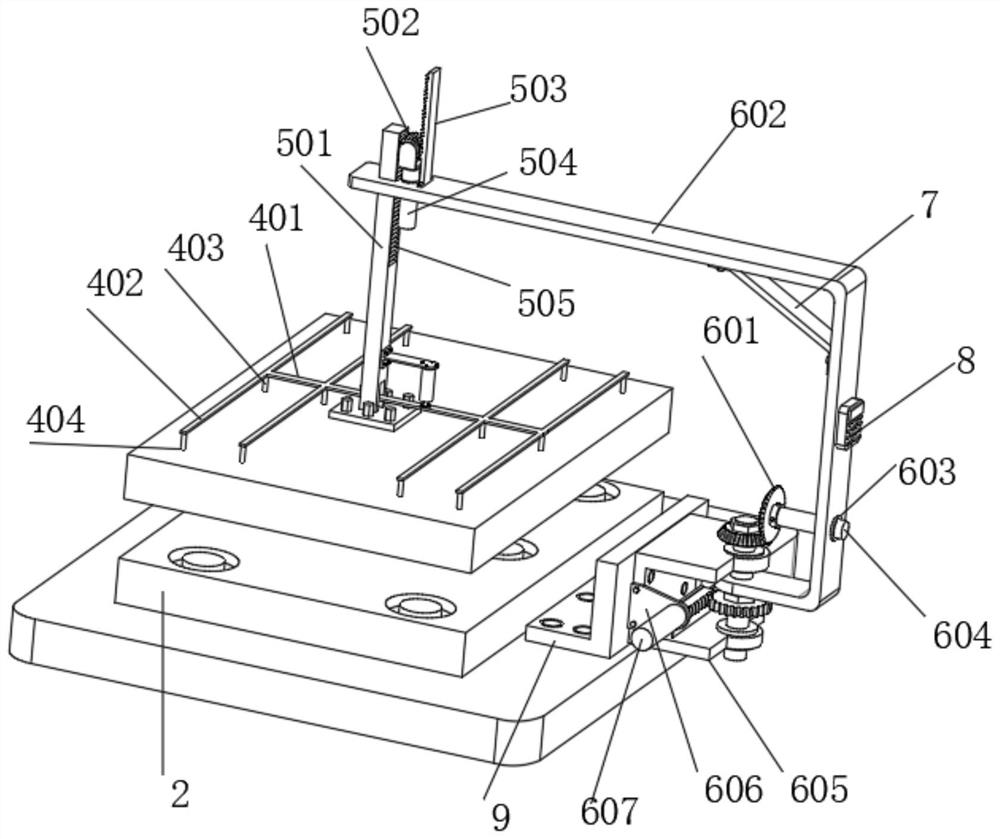

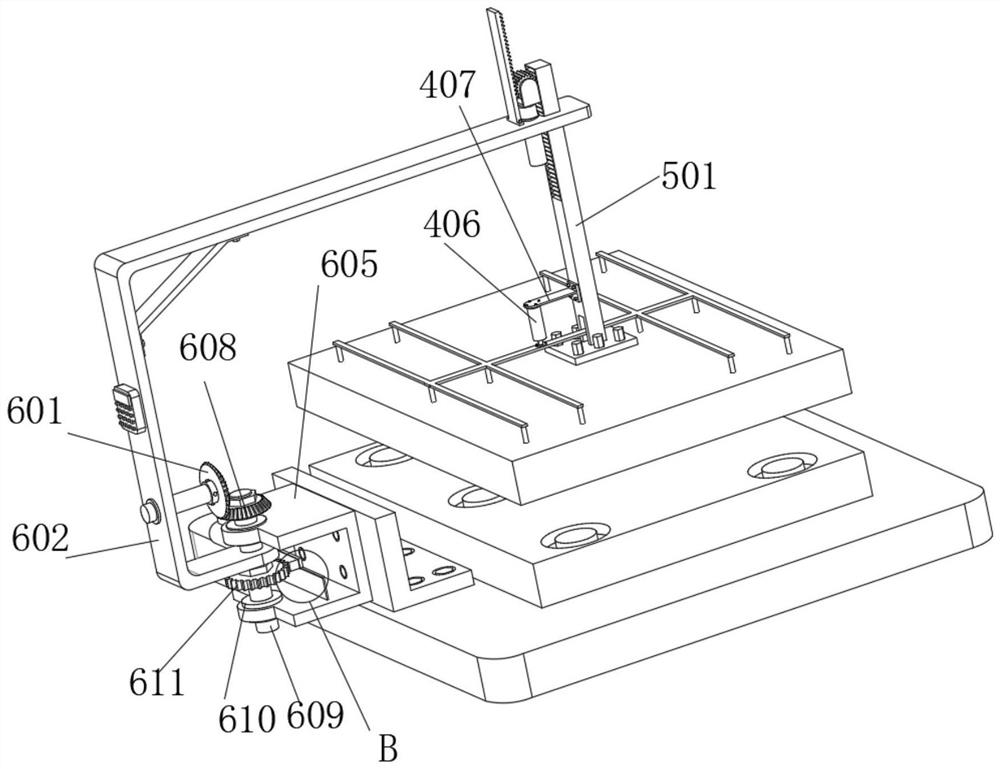

[0040] Such as Figure 1-10The advance and retreat mold device for oil seal molding machine shown includes a base plate 1, a lower mold 2, an upper mold 3 and a controller 8. The top of the base plate 1 is fixedly connected with a lower mold 2 for oil seal molding. The back side of 2 is fixedly connected with L-shaped support plate 9 by the fixed bolt of screw connection, and L-shaped support plate 9 is connected with the rotating structure 6 that is used for upper die 3 position adjustments, and rotating structure 6 comprises the first bevel gear 601, the first C Shaped plate 602, first bearing 603, first rotating rod 604, second C-shaped plate 605, second mounting plate 606, third cylinder 607, second bevel gear 608, second rotating rod 609, second bearing 610, The second ring gear 611, the second tooth plate 612 and the connecting plate 613, the L-shaped support plate 9 is fixedly connected with the second C-shaped plate 605 by bolts, and the right side wall of the second C...

Embodiment 2

[0043] Embodiment 2 is a further improvement to Embodiment 1.

[0044] Such as Figure 1-10 The advance and retreat mold device for oil seal molding machine shown includes a base plate 1, a lower mold 2, an upper mold 3 and a controller 8. The top of the base plate 1 is fixedly connected with a lower mold 2 for oil seal molding. The back side of 2 is fixedly connected with L-shaped support plate 9 by the fixed bolt of screw connection, and L-shaped support plate 9 is connected with the rotating structure 6 that is used for upper die 3 position adjustments, and rotating structure 6 comprises the first bevel gear 601, the first C Shaped plate 602, first bearing 603, first rotating rod 604, second C-shaped plate 605, second mounting plate 606, third cylinder 607, second bevel gear 608, second rotating rod 609, second bearing 610, The second ring gear 611, the second tooth plate 612 and the connecting plate 613, the right side wall of the second C-shaped plate 605 is fixedly conn...

Embodiment 3

[0046] Embodiment 3 is a further improvement to Embodiment 1.

[0047] Such as Figure 1-10The advance and retreat mold device for oil seal molding machine shown includes a base plate 1, a lower mold 2, an upper mold 3 and a controller 8. The top of the base plate 1 is fixedly connected with a lower mold 2 for oil seal molding. The back side of 2 is fixedly connected with L-shaped support plate 9 by the fixed bolt of screw connection, and L-shaped support plate 9 is connected with the rotating structure 6 that is used for upper die 3 position adjustments, and rotating structure 6 comprises the first bevel gear 601, the first C Shaped plate 602, first bearing 603, first rotating rod 604, second C-shaped plate 605, second mounting plate 606, third cylinder 607, second bevel gear 608, second rotating rod 609, second bearing 610, The second ring gear 611, the second tooth plate 612 and the connecting plate 613, the right side wall of the second C-shaped plate 605 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com