WCMP (wolfram chemical mechanical polishing) grinding device and method for improving WCMP grinding rate

A technology of grinding device and grinding liquid, which is applied in the technical field of chemical mechanical grinding (CMP), can solve the problems of difficult development of grinding liquid and grinding pad, high cost, and affecting the service life of the grinding pad, so as to improve the grinding rate, low cost, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

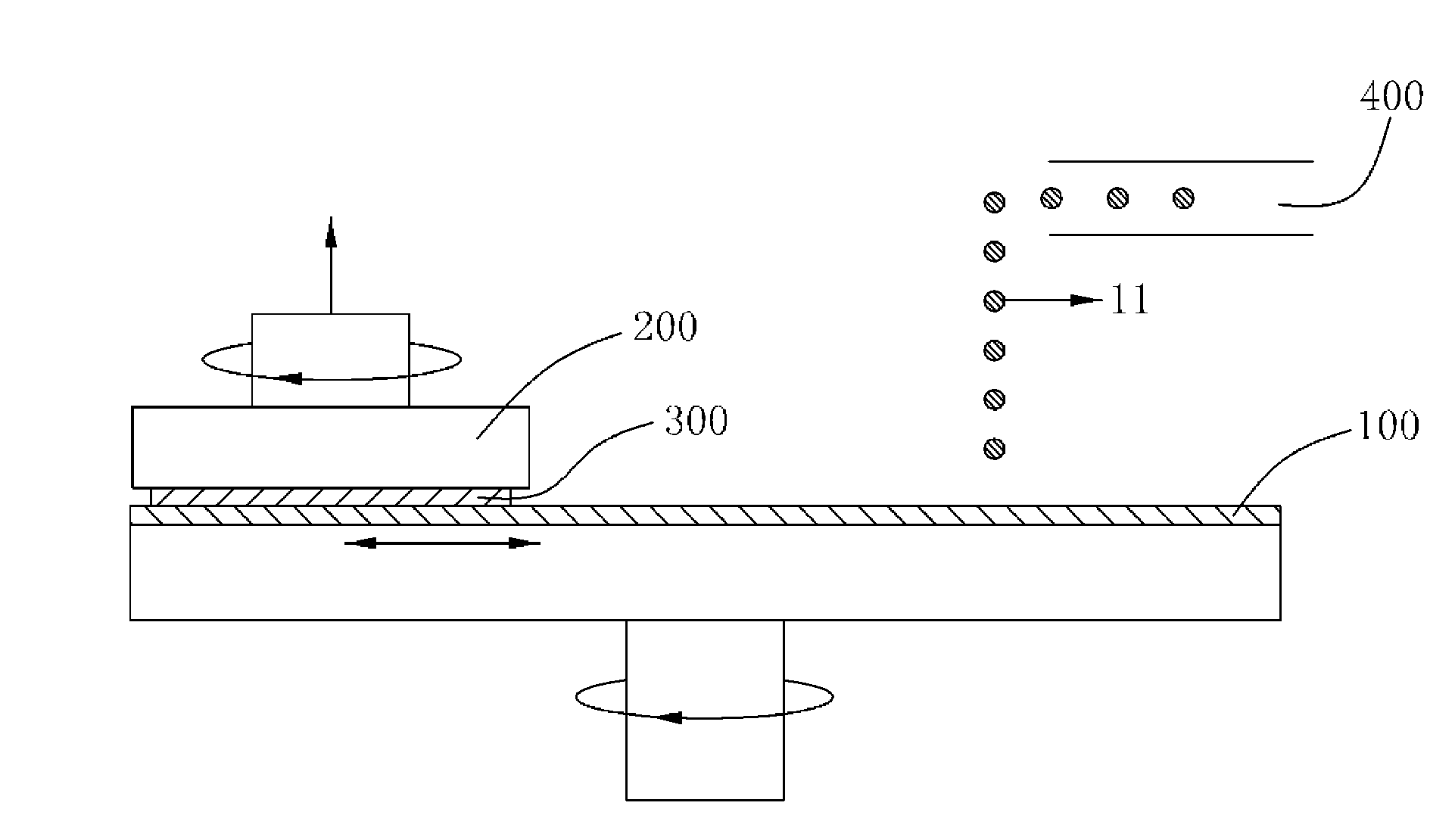

[0036] FIG. 1 is a schematic diagram showing the outline of a conventional WCMP polishing apparatus. As shown in FIG. 1 , in the prior art, a WCMP polishing device mainly includes a polishing pad 100 , a tray 200 , and a pipe portion 400 , and uses a polishing liquid 11 to polish a workpiece 300 . Specifically, the polishing liquid 11 introduced from the pipe portion 400 is carried on the polishing pad 100 , and the tray 200 holds the workpiece 300 and enables the workpiece 300 to be polished by WCMP on the polishing pad 100 . The pipe part 400 introduces a polishing liquid or slurry into the polishing pad 100 .

[0037] The inventors of the present invention have found through intensive research that during the grinding process of WCMP, the grinding rate increases with the grinding temperature when other conditions remain unchanged. Especially, in the range of 30-60°C, the grinding rate increases rapidly with the increase of the temperature of the polishing liquid, but when ...

no. 2 approach

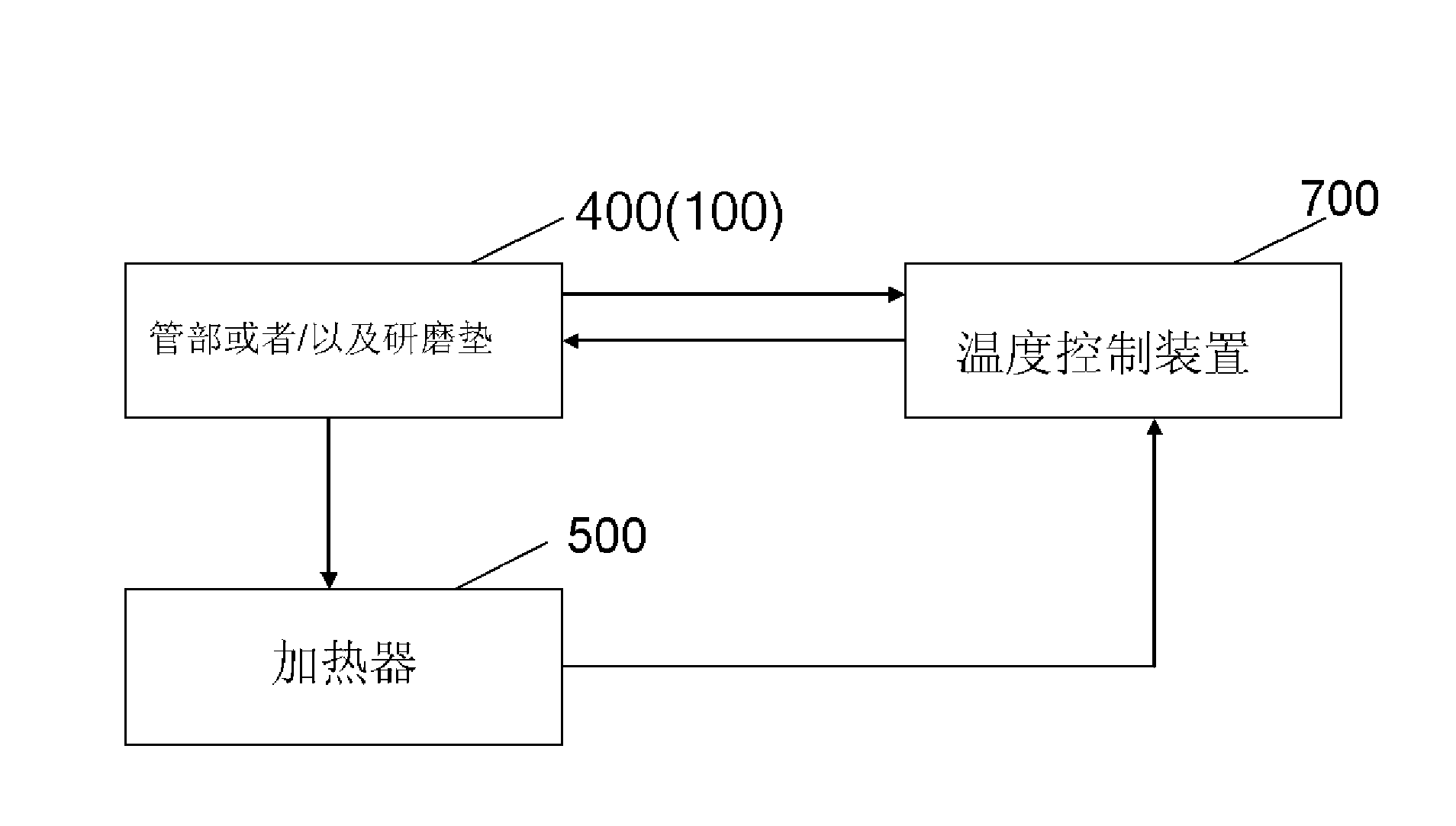

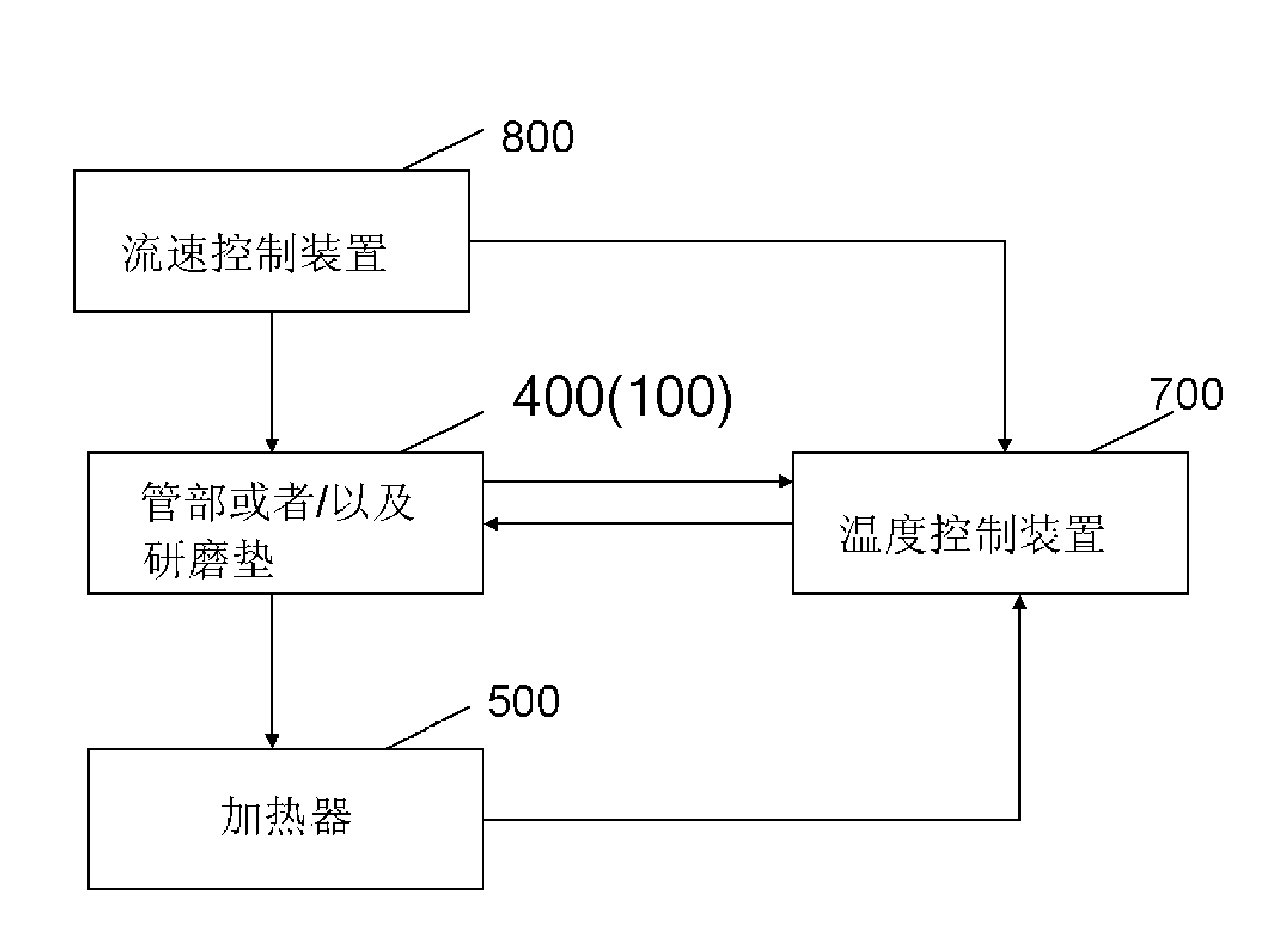

[0045] On the basis of the above, the inventors of the present invention have found through intensive research that the flow rate of the polishing liquid flowing in the pipe portion 400 is also closely related to the temperature of the polishing liquid. Therefore, on the basis of the above-mentioned first embodiment, the following second embodiment will be described.

[0046] FIG. 3 is a block diagram showing a partial structure of a WCMP polishing apparatus according to a second embodiment of the present invention.

[0047] That is, on the basis of the structure shown in FIG. 1 , a heating device 500 , a temperature control device 600 , and a flow rate control device 800 are further added. The heating device 500 is used for heating the pipe part 400 or the polishing pad 100 , or / and the heating device 500 is used for heating the pipe part 400 and the polishing pad 100 , so that the temperature of the polishing liquid 11 flowing in the pipe part 400 is increased. The flow rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com