Food material milling processing device

A kind of processing equipment and powder grinding technology, which is applied in the field of food material powder processing equipment, can solve the problems of long grinding time and low work efficiency, and achieve the effects of small vibration, convenient grinding and water reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

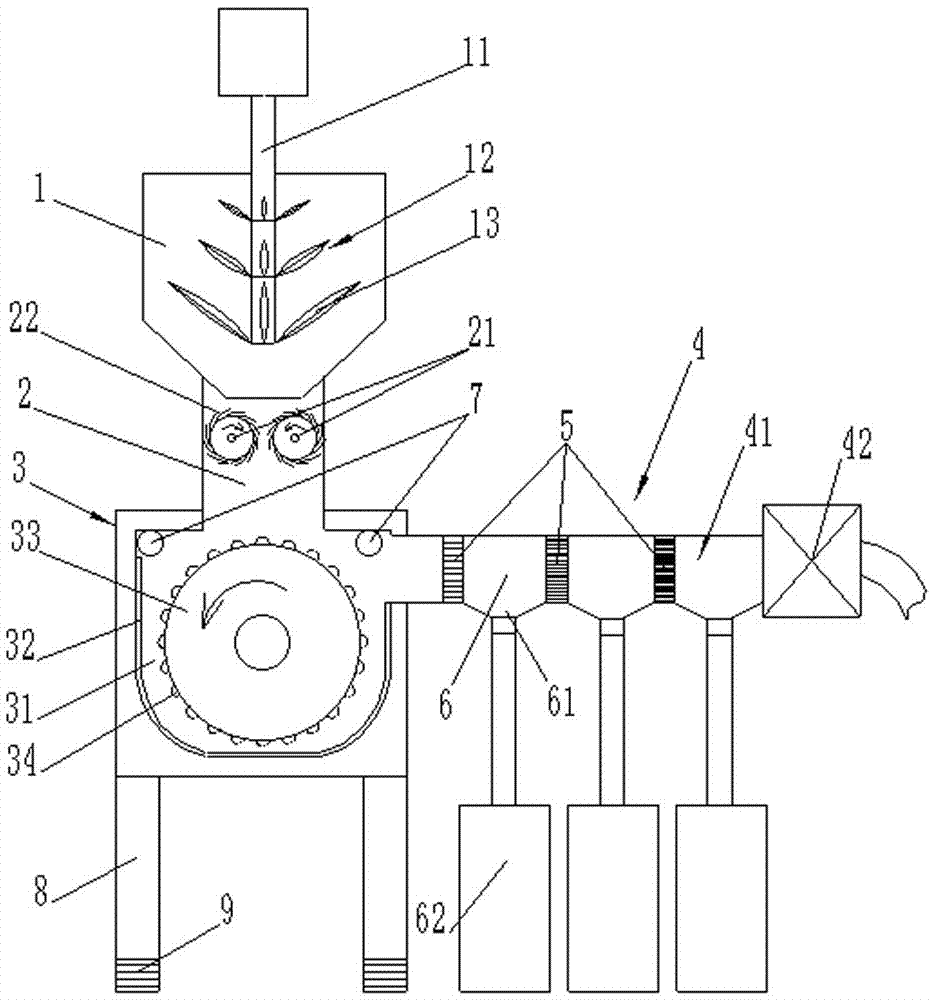

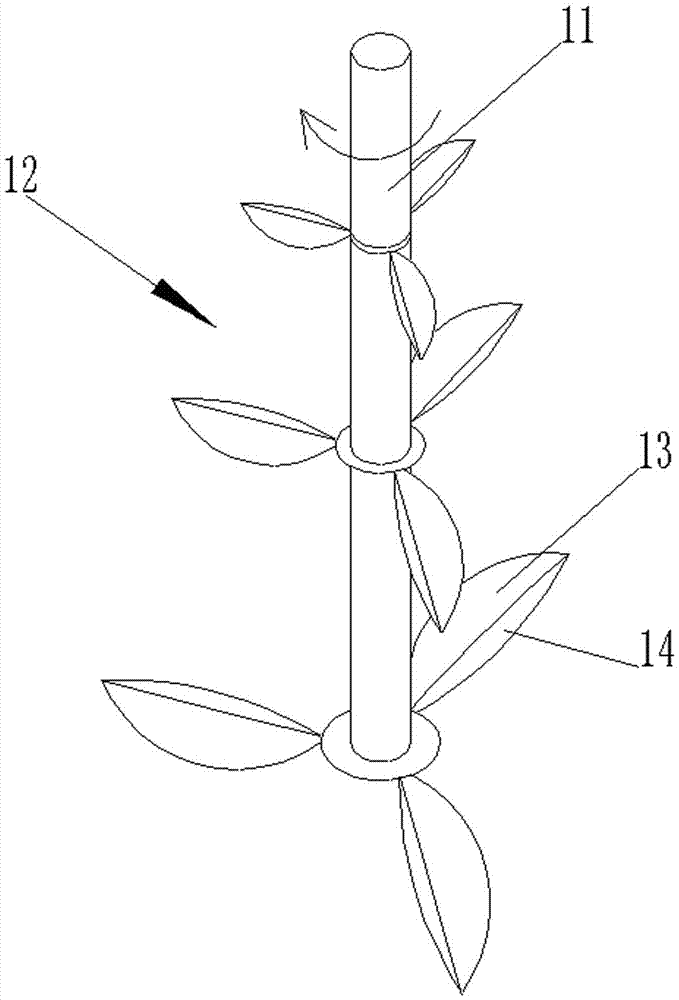

[0022] see Figure 1-2 , a food material grinding processing equipment, including a discharge mechanism 4 and a crushing hopper 1, a material cutting channel 2 and a grinding box 3 arranged sequentially from top to bottom; an abrasive chamber 31 is arranged in the grinding box 3; material cutting The upper end of the channel 2 is connected to the lower end of the crushing hopper 1, and the lower end of the cutting channel 2 is connected to the abrasive chamber 31; the middle part of the crushing hopper 1 is provided with a vertically placed stirring shaft 11, and the stirring shaft 11 is provided with a crushing knife group 12; 31 is provided with a grinding layer 32 on the inner wall, and a horizontally placed grinding roller 33 is arranged in the abrasive chamber 31, and abrasive grains 34 are densely arranged on the outer surface of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com