Grinding liquid supply and grinding pad trimming device and grinding drilling crew

A grinding machine and finishing device technology, which is applied in the direction of grinding devices, grinding machine tools, abrasive surface adjustment devices, etc., can solve the problems of wafer surface scratches, grinding rate reduction, silicon wafer scrapping, etc., to reduce costs and increase grinding rate , the effect of increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, features and advantages of the present invention more obvious and easy to understand, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. The parts showing the structure and positional relationship in the drawings may not be drawn to scale.

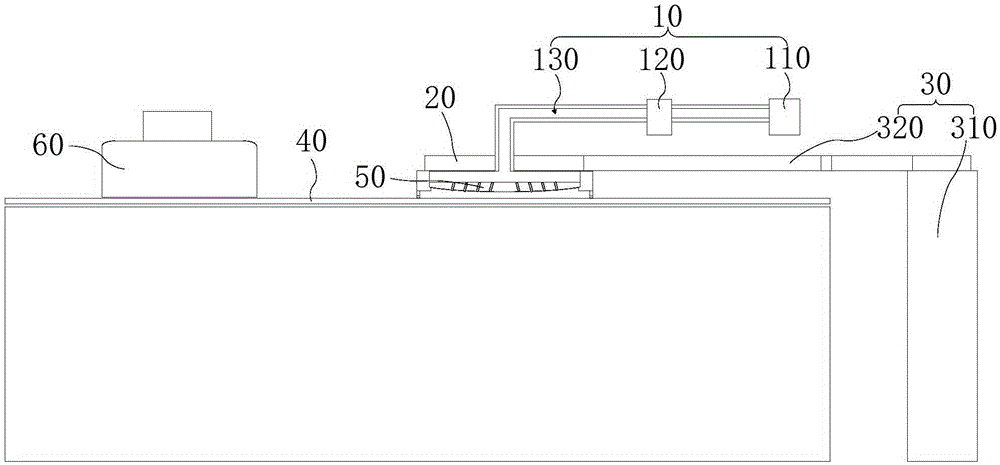

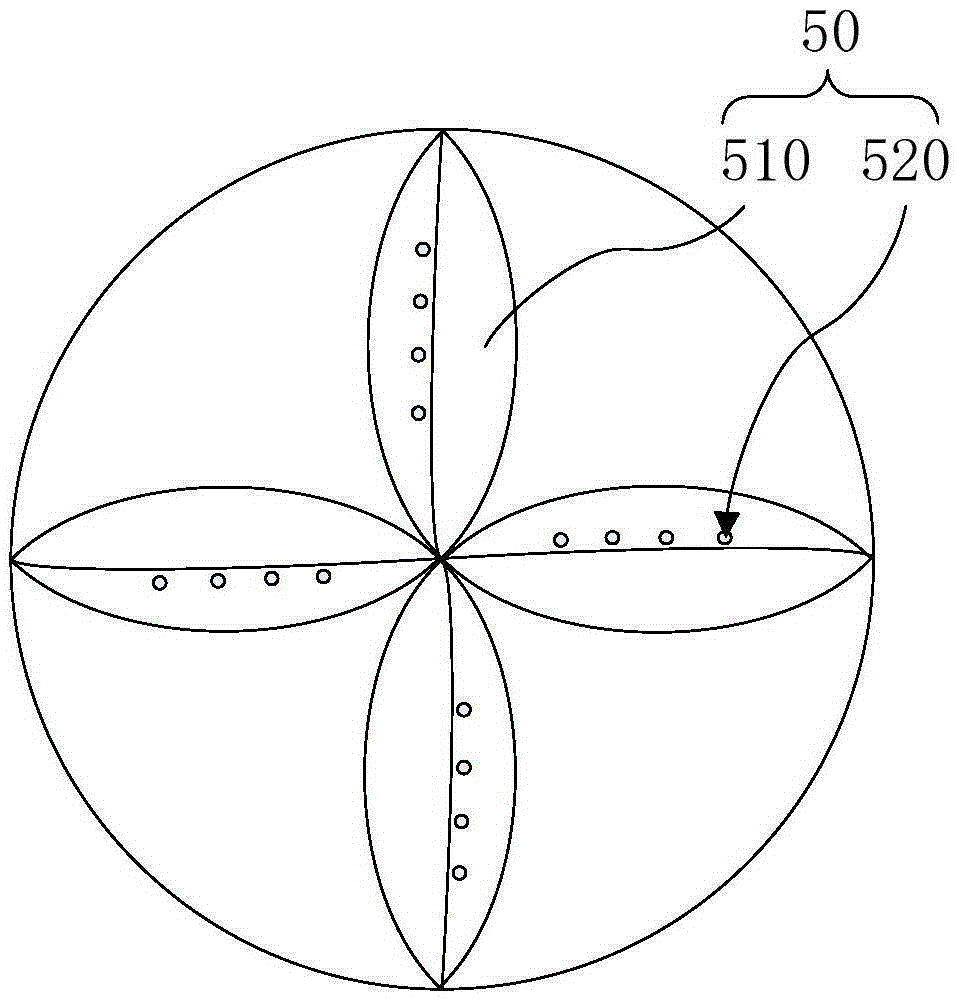

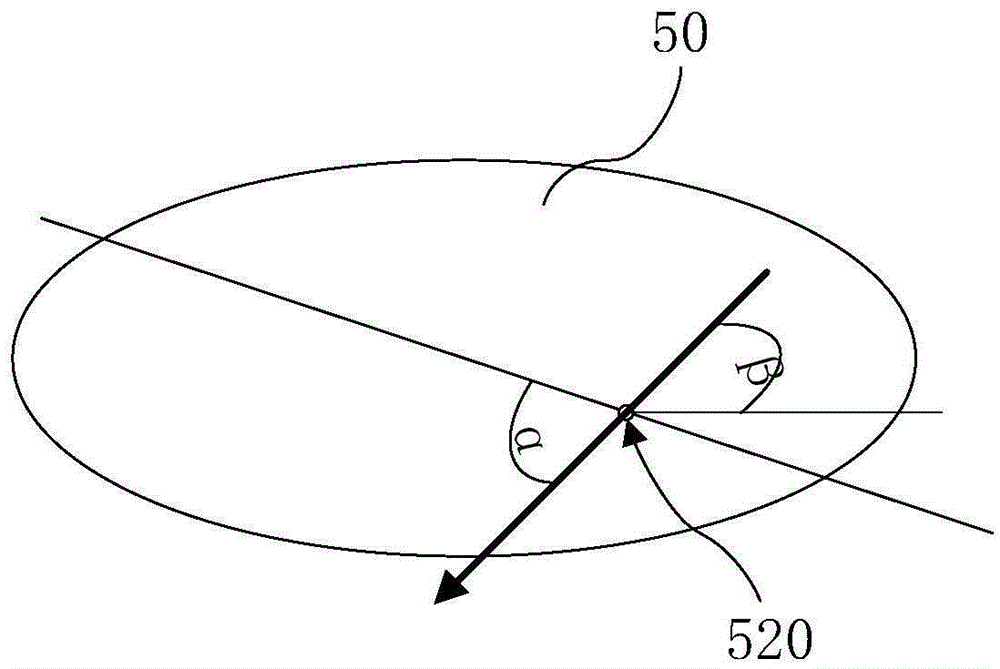

[0024] The invention provides a grinding liquid supply and grinding pad finishing device, a grinding machine platform, such as figure 1 As shown, it includes a grinding liquid supply system 10, a cavity 20 communicated with the grinding liquid supply system 10, a drainage plate 50 with a plurality of drainage holes arranged in the cavity 20, and a load carrying and capable of driving the cavity. 20 drive system 30 . Wherein, the grinding liquid supply system 10 supplies a pressurized grinding liquid with a pressure greater than or equal to 50Mpa, and the pressurized grinding liquid is sprayed onto the grinding pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com