Carbamate resin composition for polishing pad and polyurethane polishing pad

A technology of urethane and resin composition, which is applied in the field of polyurethane grinding pads, can solve the problems of several months of curing time, the lack of grinding pads, and unstable quality. scratchy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

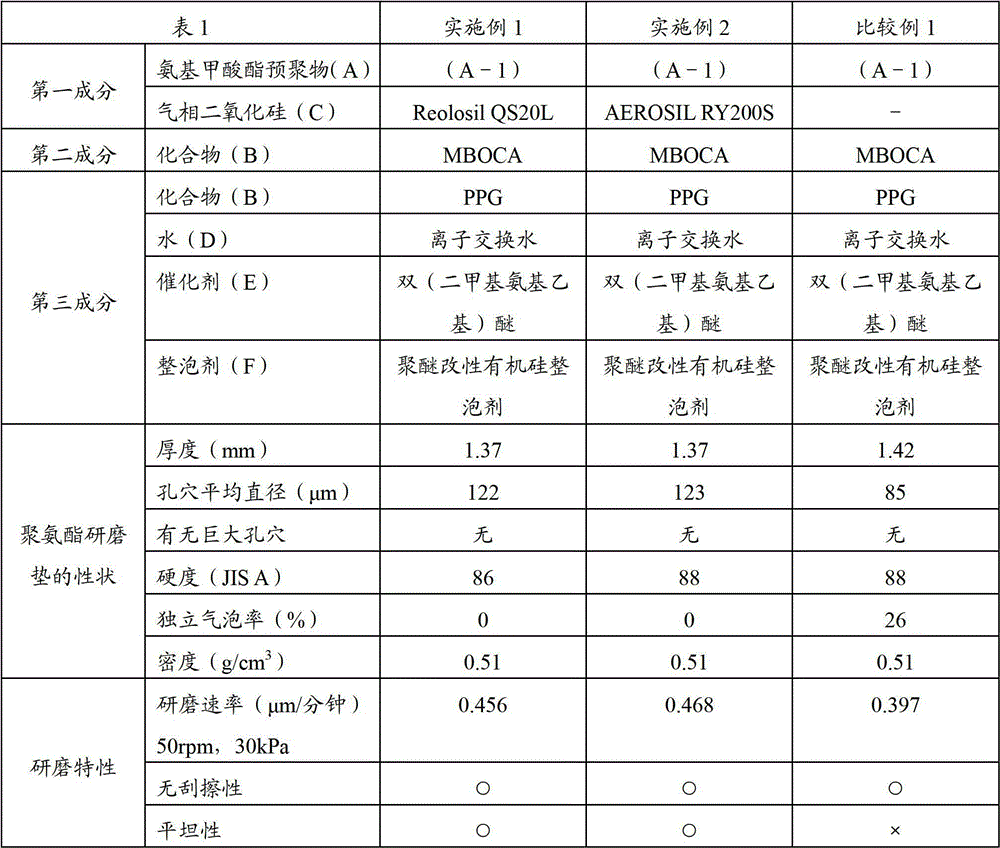

[0078] [Example 1] "Manufacture of Polyurethane Polishing Pad (P-1)"

[0079] 37 parts by mass of toluene diisocyanate ("TDI-100", manufactured by Nippon Polyurethane Industry Co., Ltd.) was placed in a 4-necked round-bottomed flask equipped with a nitrogen gas inlet tube, a cooling condenser, a thermometer, and a stirrer, and stirring was started. Next, 63 parts by mass of polytetramethylene glycol (number-average molecular weight: 1000) was added and mixed, and reacted at 60°C for 8 hours under a nitrogen stream to obtain a urethane prepolymer with an isocyanate group equivalent of 335 (A -1). To the obtained urethane prepolymer (A-1), 1.25 parts by mass of hydrophilic silica (trade name: "Reolosil QS20L", specific surface area = 220m 2 / g, manufactured by Tokuyama Co., Ltd.), fully mixed in a Disper disperser to form the first component. The isocyanate group equivalent weight of the obtained first component was 342.

[0080] Next, 3,3'-dichloro-4,4'-diaminophenylmethane ...

Embodiment 2

[0088] [Example 2] "Manufacture of Polyurethane Polishing Pad (P-2)"

[0089] In addition to changing the hydrophilic silica (trade name: "Reolosil QS20L") to hydrophobically modified fumed silica (trade name: "AEROSIL RY200S", specific surface area = 130m 2 / g, manufactured by Nippon Aerosil Co., Ltd.), a polyurethane polishing pad (P-2) was obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com