Efficient boron carbide grinding fluid and method for preparing same

A boron carbide and grinding fluid technology, which is applied in the field of high-efficiency boron carbide grinding fluid and its preparation, can solve the problems of long processing time of boron carbide grinding fluid, increased machine and labor costs, and high processing difficulty, so as to reduce processing costs and improve Service life, the effect of increasing the grinding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment, the present invention will be further described. The following description is by way of example, but the protection scope of the present invention should not be limited thereto.

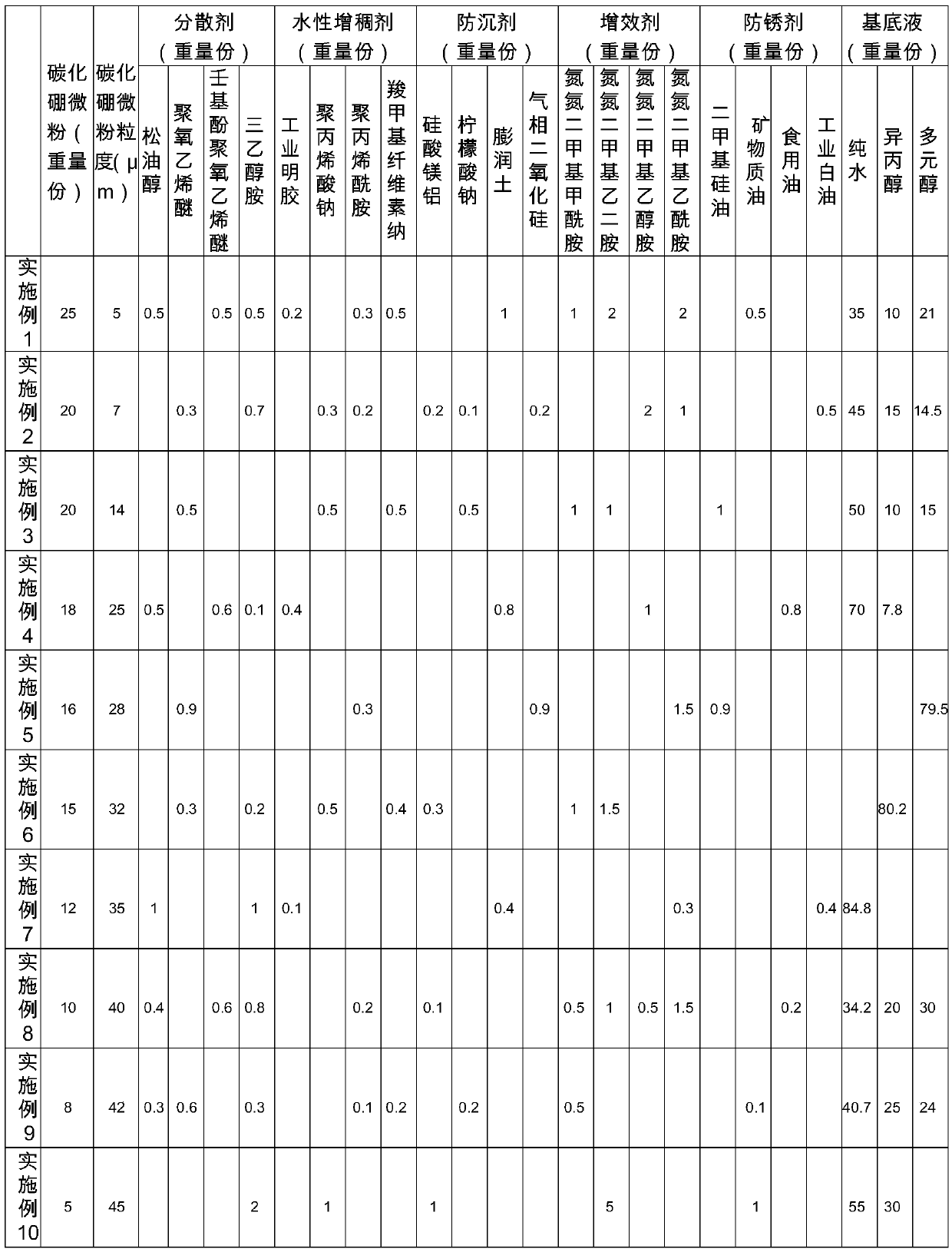

[0028] The following Table 1 provides 10 groups of examples, and the data in the table are parts by weight of raw materials used.

[0029] Each embodiment in table 1, its preparation steps are as follows:

[0030] A. First, clean the boron carbide micropowder with pure water for 2-3 times, wash away impurity ions, and filter dry to obtain boron carbide micropowder;

[0031] B. Mix the dried boron carbide micropowder with the base liquid evenly, filter with a 400-mesh sieve, remove large particles of impurities, and obtain a mixed liquid;

[0032] C. Add a dispersant and an anti-sedimentation agent to the mixed solution, put it into a closed high-speed dispersion tank, and disperse for 5 minutes at a speed of 1100 rpm to obtain an initial mixed solution; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com