A multifunctional copper belt machine

A multi-functional, copper tape technology, used in forming tools, safety equipment, metal processing equipment, etc., can solve the problems of not grasping the wire, squeezing to one side, squeezing to one side, and generating burrs, so as to improve the alignment accuracy. , Effective treatment, the effect of improving the outflow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

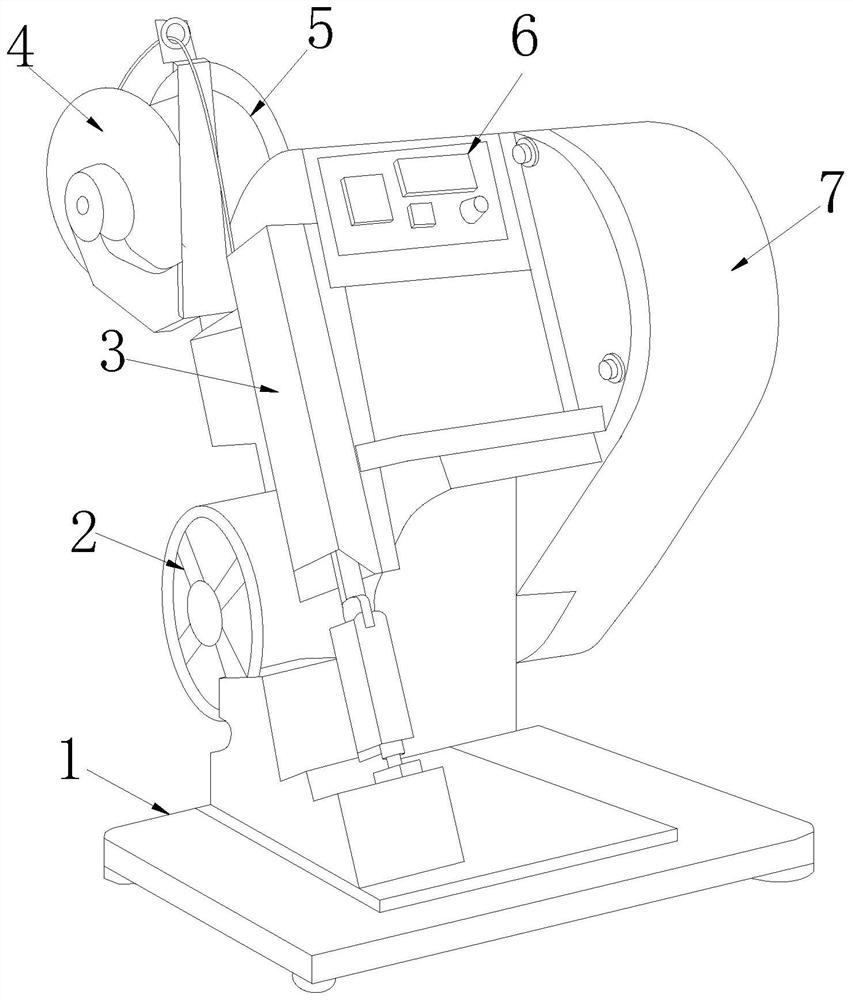

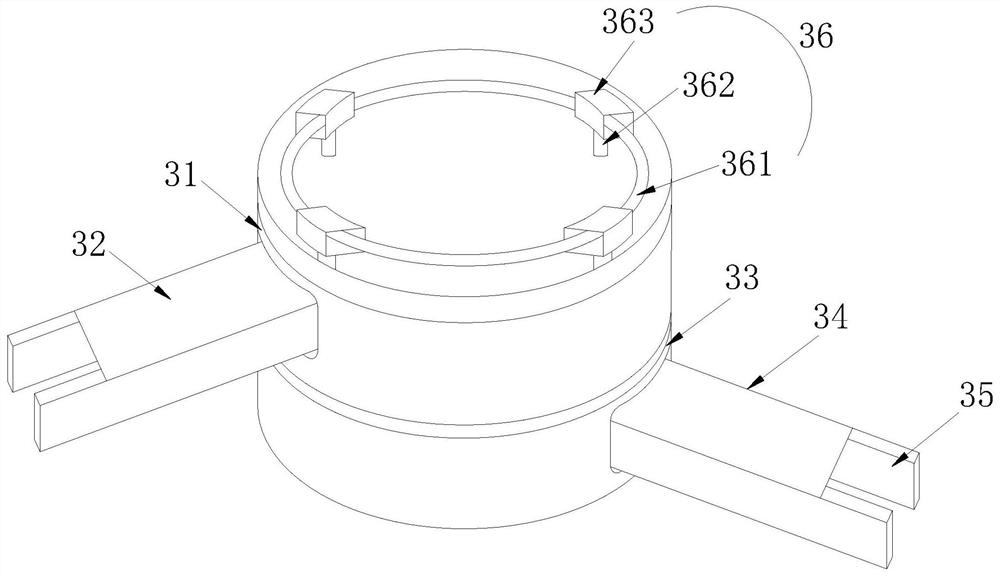

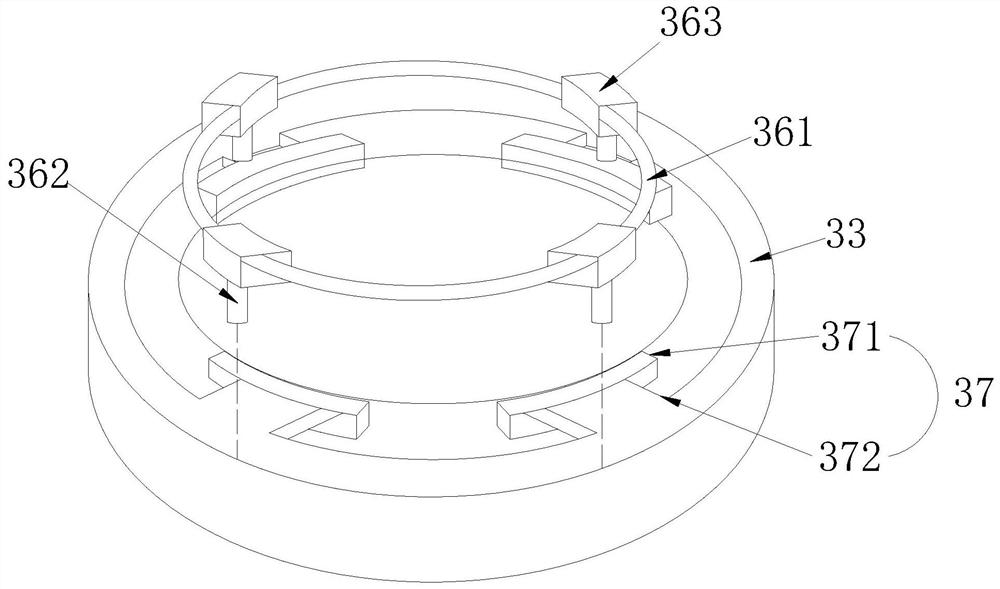

[0027] Such as Figure 1-Figure 3 As shown, the present invention provides a kind of multi-functional copper tape machine, and its structure comprises base 1, traction wheel 2, mold holder 3, feeding wheel 4, line reel 5, control panel 6, main control box 7, and described main control The box 7 is installed on the side of the mold base 3, the mold base 3 is fixed on the base 1, the outer surface of the mold base 3 is provided with a control panel 6, and the control panel 6 is electrically connected to the main control box 7 , the back side of the mold base 3 is mechanically connected with a feeding wheel 4 and a wire management disc 5, and a copper belt is connected between the wire management disc 5 and the feeding wheel 4, and the mold base 3 includes an upper mold 31, an upper mold Shaft 32, lower die 33, lower die shaft 34, cutter loading port 35, mold seat aligner 36, alignment member 37, described upper die 31 and lower die 33 are arranged up and down, and described uppe...

Embodiment 2

[0029] Such as Figure 4-Figure 5 As shown, the alignment shaft 362 is composed of a vertical shaft 62a, a plug 62b, an input port 62c, a protective cover 62d, an output port 62e, a driver 62f, an inner collection cover 62g, and a balance seat 62h. Both sides of the vertical shaft 62a A top 62b is provided, and the inside of the protective cover 62d is provided with an inner collection cover 62g, a balance seat 62h, and an output port 62e, and the output port 62e is fixed on the balance seat 62h, and the vertical shaft 62a is matched with the calibration groove 372, The driver 62f controls the opening and closing of the output port 62e, and the tip of the plug 62b is provided with an input port 62c, which is matched with the protective cover 62d, and the output port 62e is provided with a port communicating with the inner collection cover 62g. port, the output port 62e is externally connected to the pipeline, the plug 62b is made of rubber, and contacts both sides of the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com