Efficient ammonium sulfate overflow groove tail gas treatment device

A technology of exhaust gas treatment and full flow tank, applied in gas treatment, ammonium sulfate, membrane technology, etc., can solve problems such as unorganized emission of exhaust gas, air pollution, and impact on employees' health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0029] In the present invention, in the absence of a contrary description, the orientation words such as "upper, lower" and the like included in the term only represent the orientation of the term in the normal use state, or the common name understood by those skilled in the art, and should not be viewed as a limitation of this term.

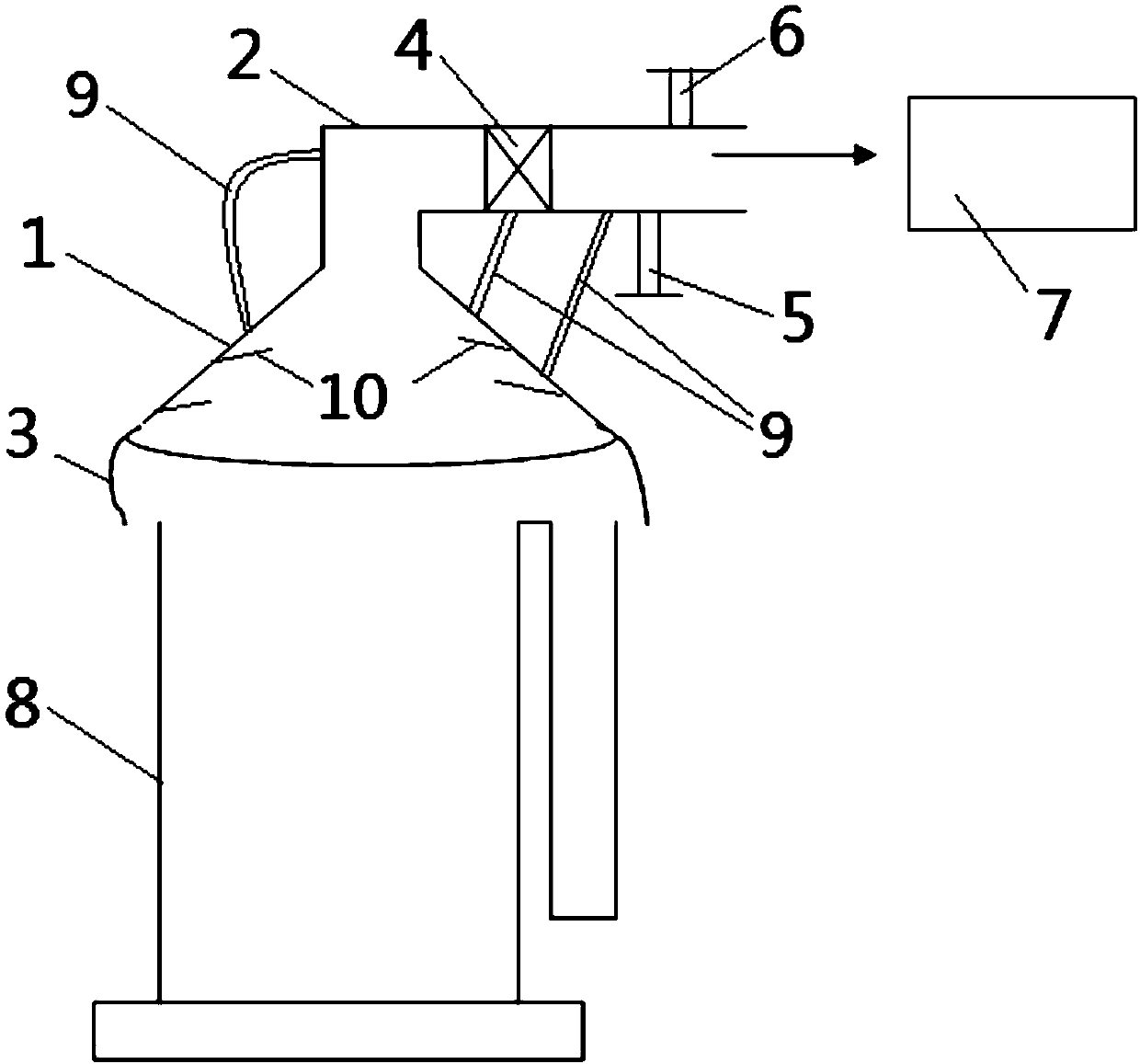

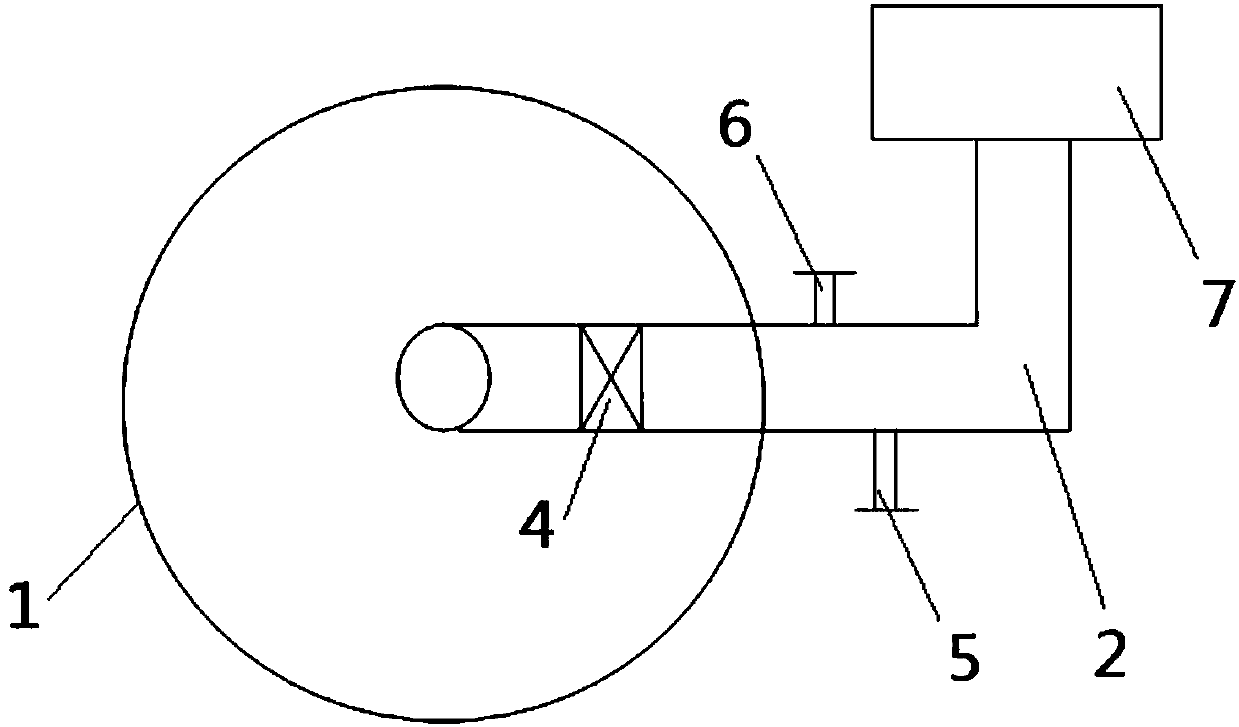

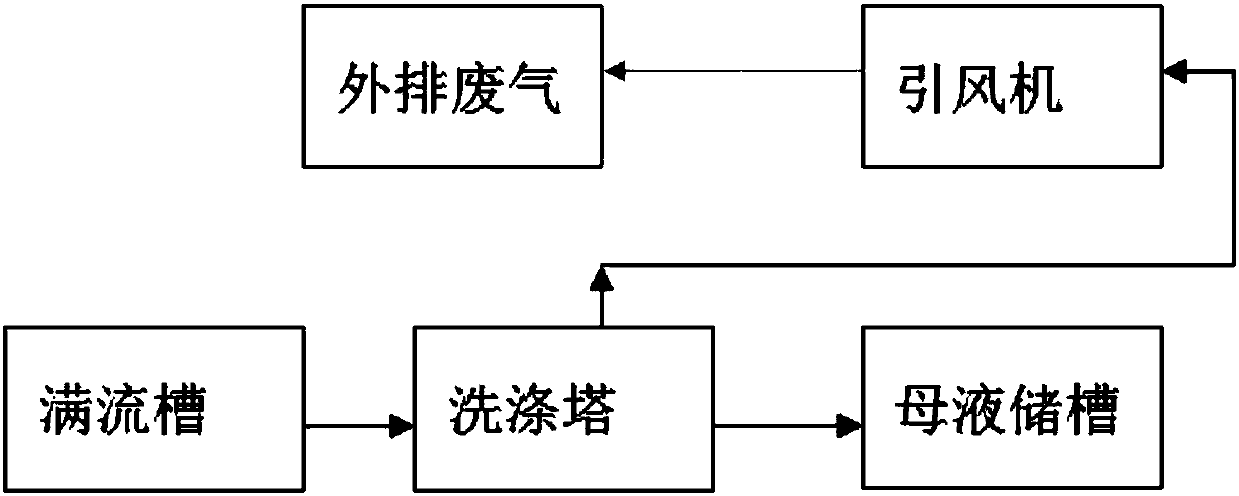

[0030] The invention provides a high-efficiency ammonium sulfate full flow tank tail gas treatment device, such as Figure 1-3 As shown, it includes a cylinder 1 and a connecting pipe 2 with openings at both ends; the cylinder 1 is arranged on the top of the full flow tank 8, and the top of the cylinder 1 communicates with the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com