Tool grinding machine

A tool grinding machine and tool technology, which is used in grinding machines, manufacturing tools, grinding machine beds, etc., can solve problems such as increased scrap rate, tool blade grinding angle not on the correct specific surface, and reduced work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

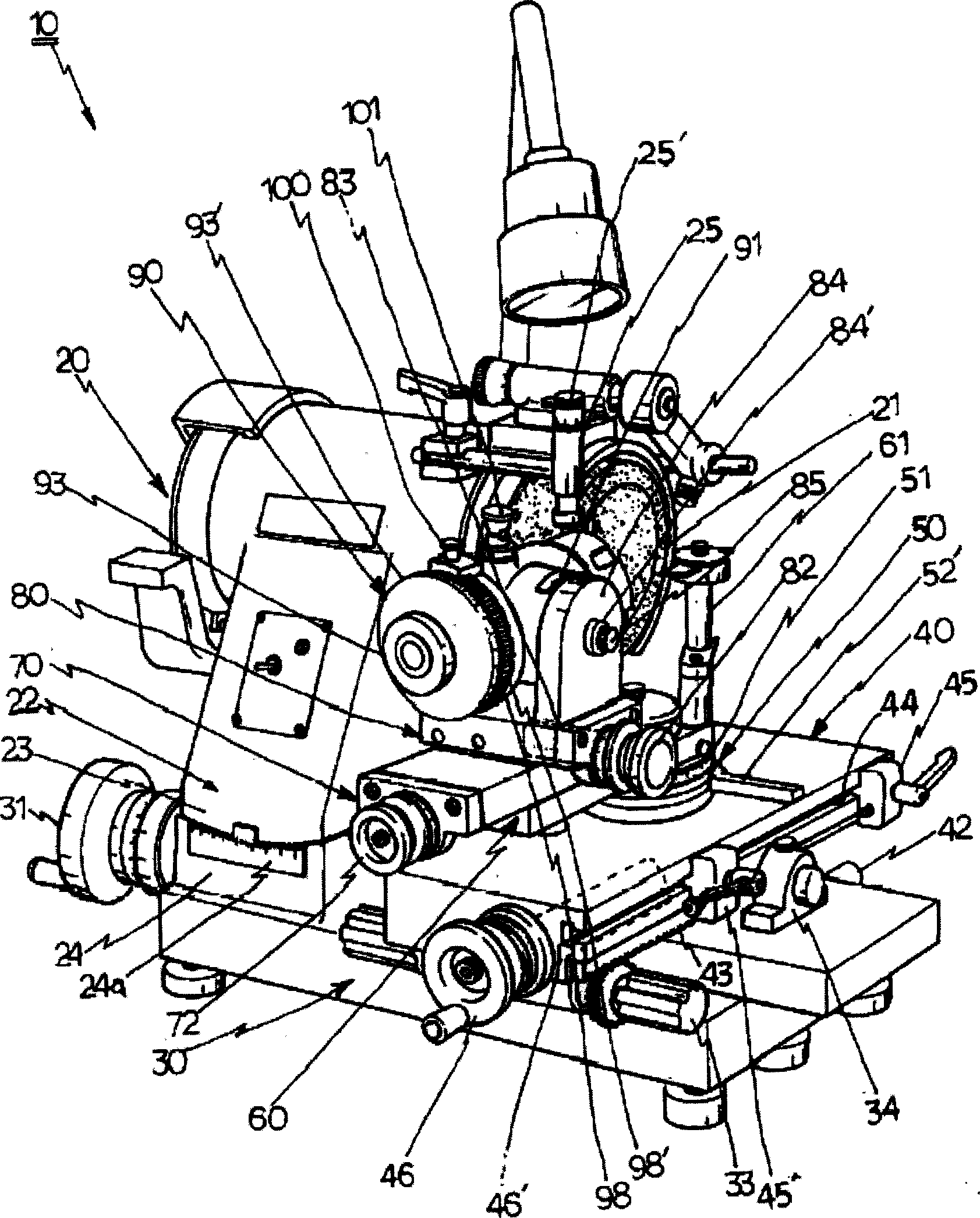

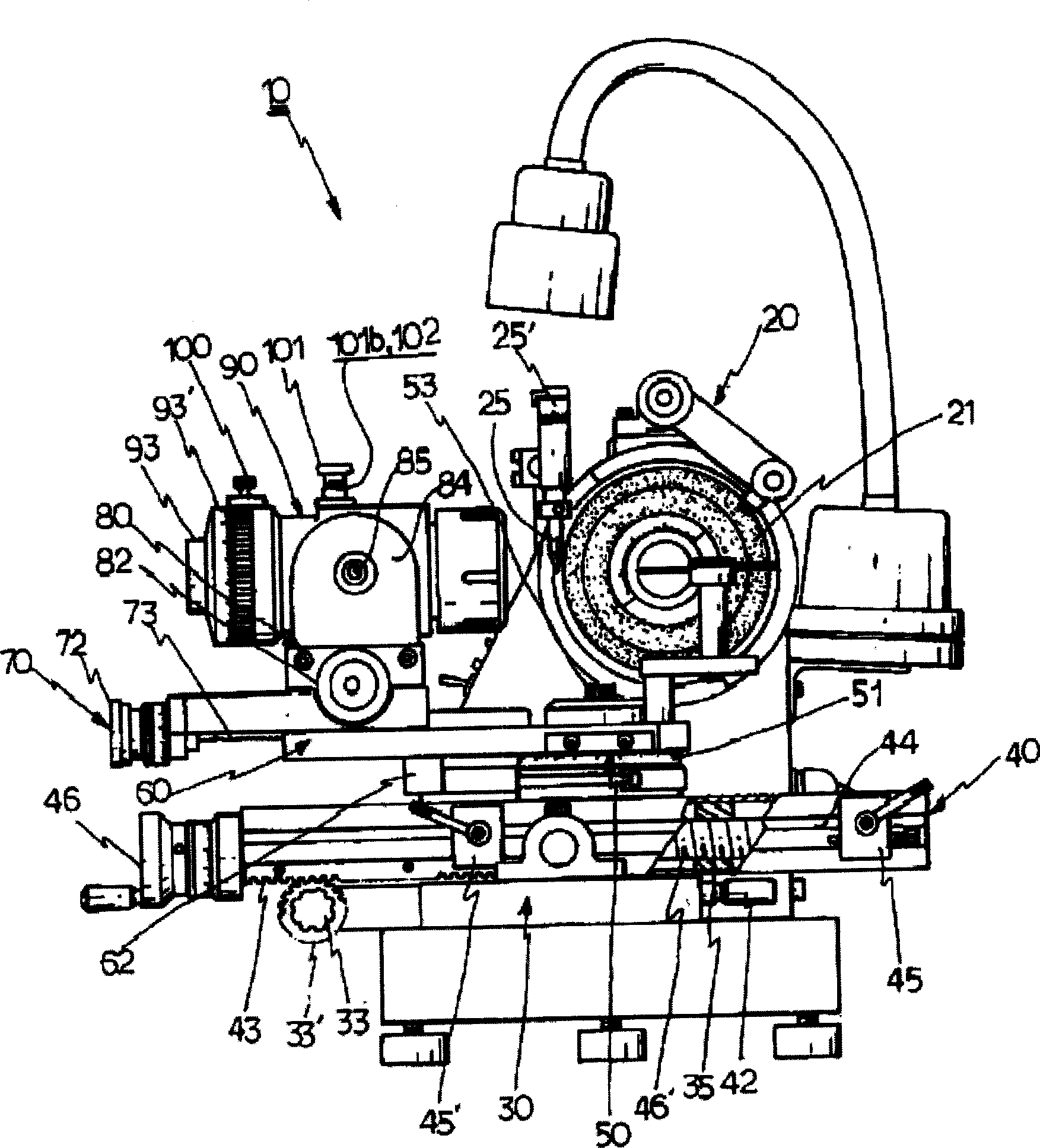

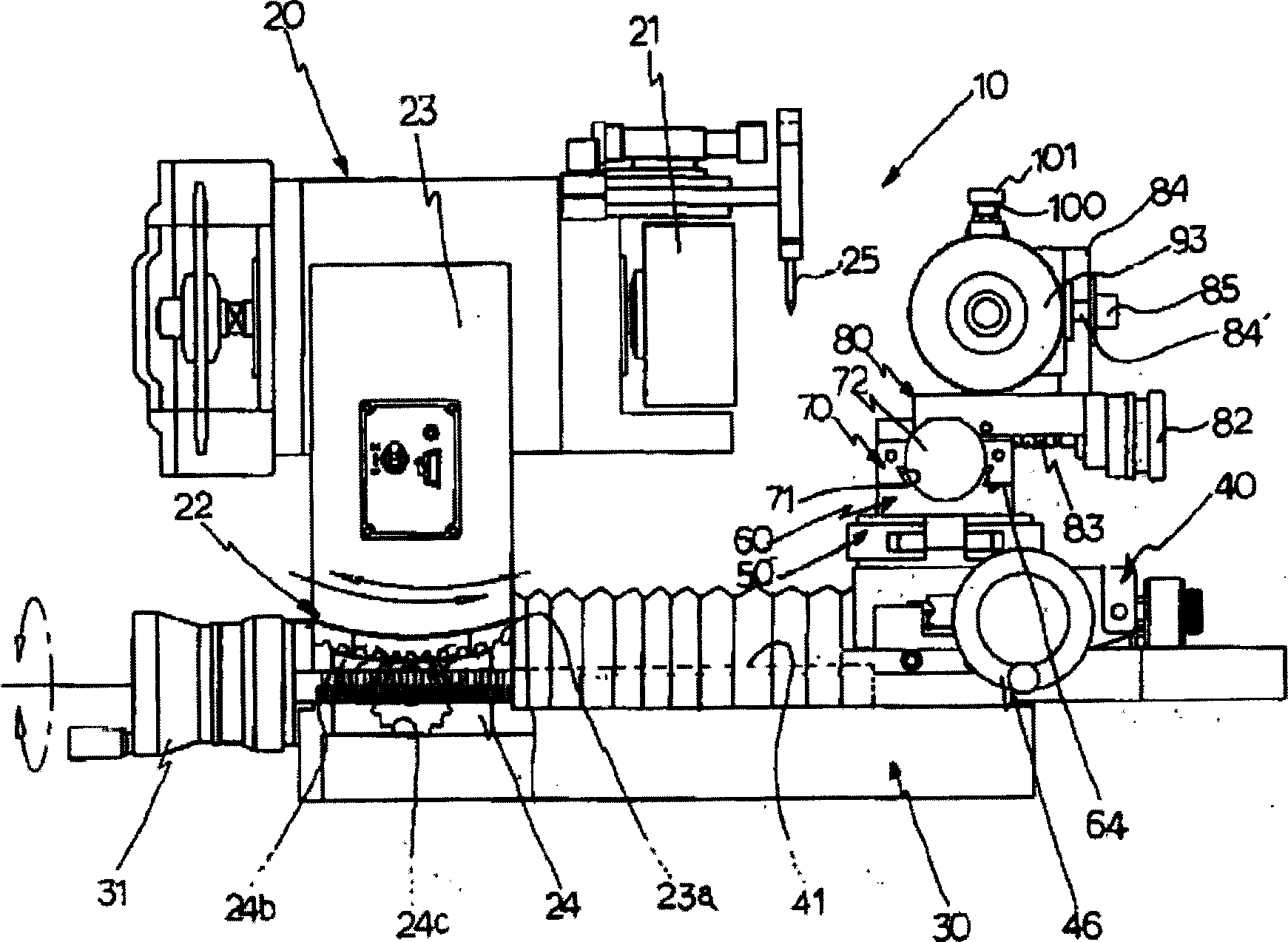

[0030] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

[0031] A whetstone 21 driven by a driving motor (not shown) is provided at an axial end of the grinding portion 20 inside the main body 10 . Below the grinding part 20, a relief angle adjusting member 22 is arranged, and the relief angle adjusting member 22 is divided into an upper rotating member 23 and a lower fixing member 24, wherein an arc-shaped relief angle scale plate 24a is arranged in front of the fixing member 24 , and a plurality of bolts 24b are engaged with the back of the fixing member 24, wherein, after setting the relief angle value of the rotating member by opening the rotating member 23, the rotating member 23 can be fixed by bolts. Between the rotating member 23 and the fixing member 24, an arc-shaped rack 23a is formed in the rotating member 23, and a spur gear 24c is formed in the fixing member 24, so that the rotating member 23 can rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com