Small-caliber aspherical composite precise processing machine tool

A precision machining and aspheric technology, applied in the field of small-caliber aspheric compound precision machining machine tools, can solve the problems of reducing machining efficiency, installation error, tool setting error, etc., to improve machining accuracy and efficiency, reduce installation errors, and prevent interference. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

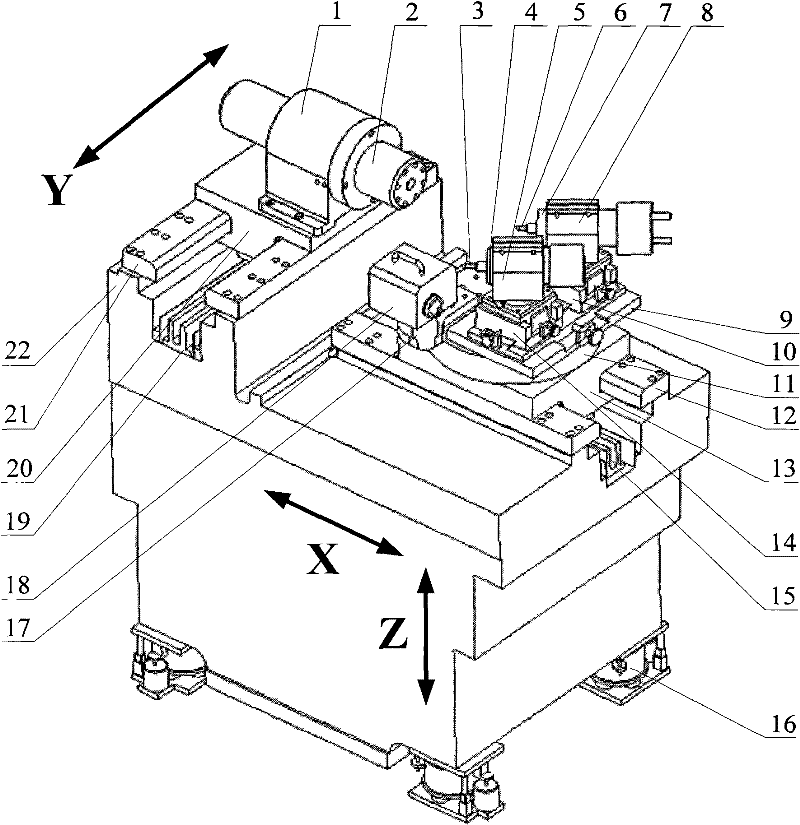

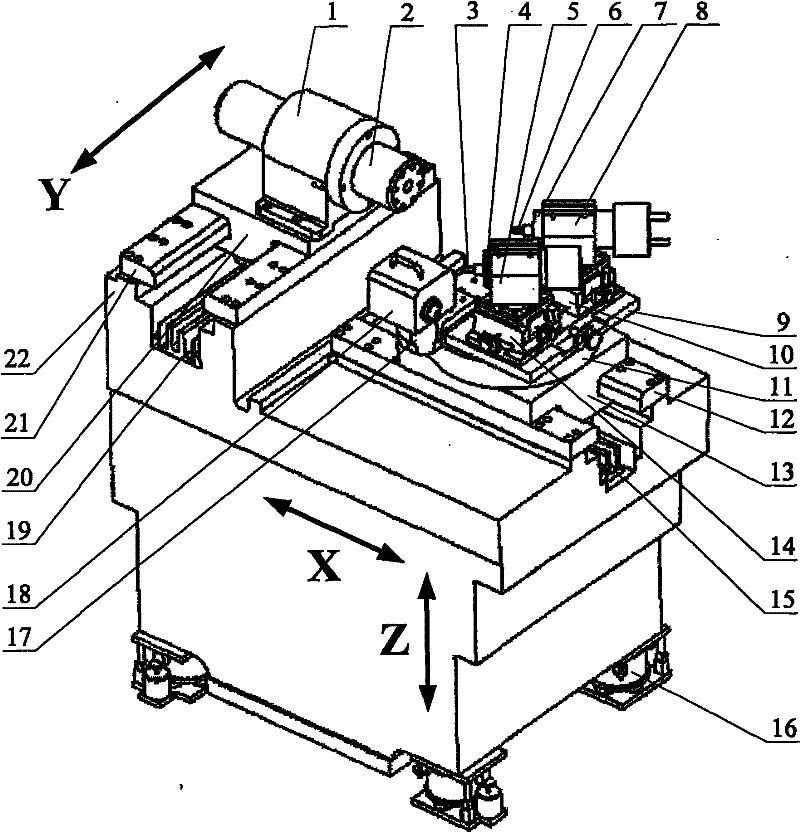

[0024] See attached figure 1 , this embodiment of the small-caliber aspheric compound precision machining machine tool of the present invention adopts the ULPG type ultra-precision machine tool with a shock absorber manufactured by the Micro-Nano Manufacturing Institute of the National High-efficiency Grinding Engineering Technology Research Center of Hunan University in China, and utilizes the four corners of the distribution The shock absorber 16 creates a smooth processing environment for the natural marble bed body 22 .

[0025] The first static pressure guide rail 21 adopts gas static pressure granite guide rails, two of which are laid and installed on the left side of the upper surface of the bed body 22, and the first linear motor 19 carried by it adopts the Aerotech ABL1500 linear motor produced by Beijing Amate Technology Co., Ltd. . The first slide table 20 is formed by casting aluminum alloy, and is installed between the above two first static pressure guide rails ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com