Grinding device of shallow trench isolation structure and method therefor

A technology of isolation structure and grinding device, applied in grinding device, grinding automatic control device, grinding machine tool, etc., can solve the problem of not being able to stop grinding at the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

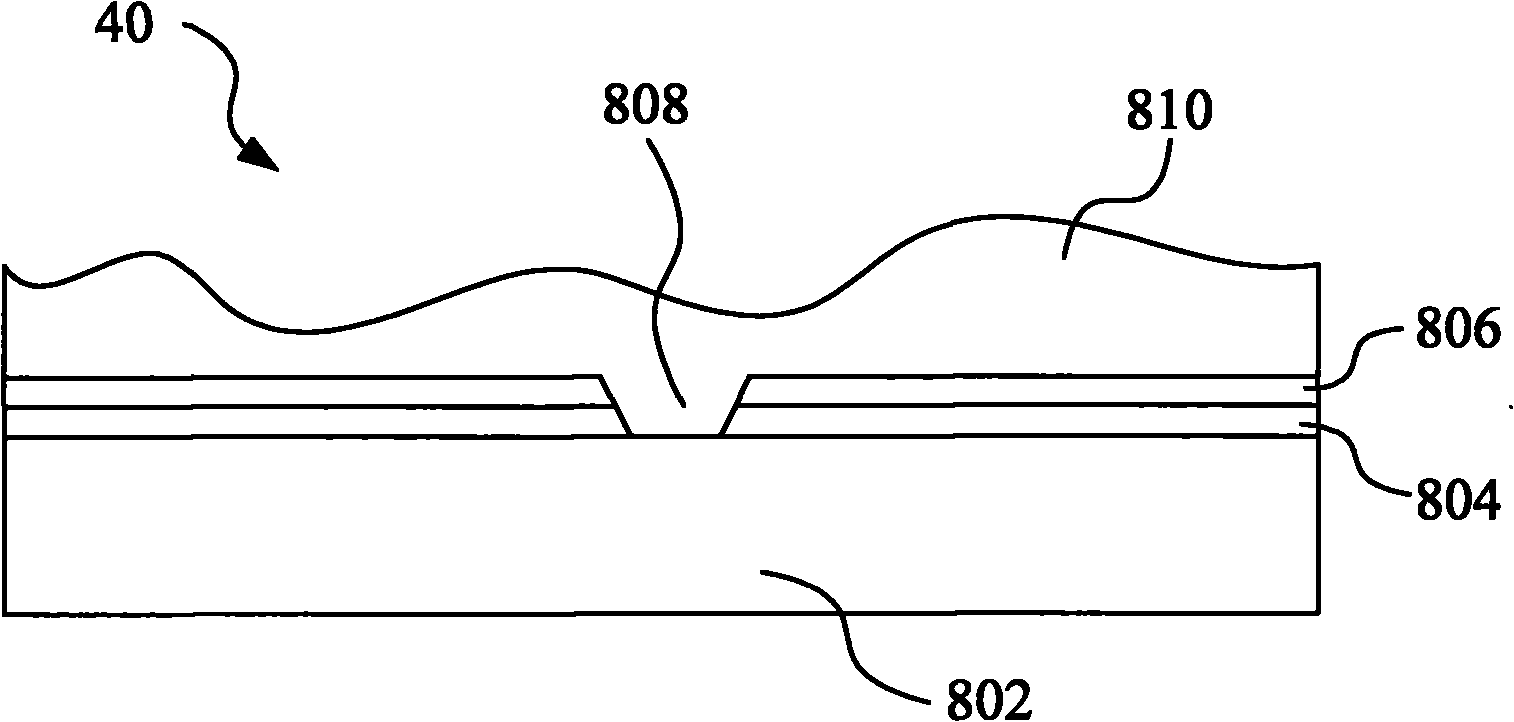

[0026] Such as figure 1 As shown, a shallow trench isolation structure formed on a wafer 40 includes a substrate 802, a first SiO formed on the substrate 802 2 layer 804, SiN layer 806, trench 808, and a second SiO formed on SiN layer 806 and within trench 808 2 Layer 810. For subsequent process requirements, in the second SiO 2 After the layer 810 is formed, it needs to be polished, and the end point of the grinding is between the SiN layer 806 and the second SiO 2 layer 810 interface.

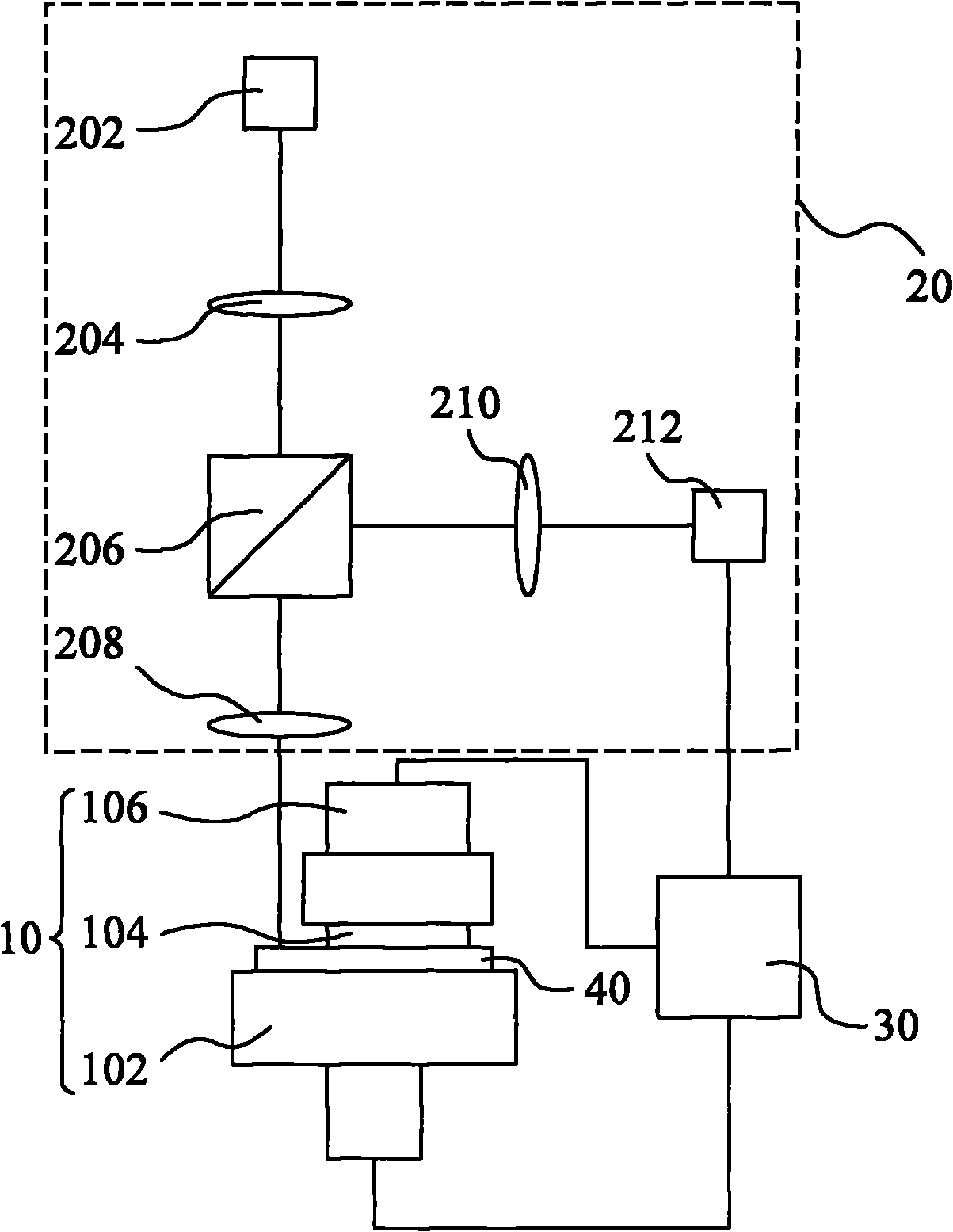

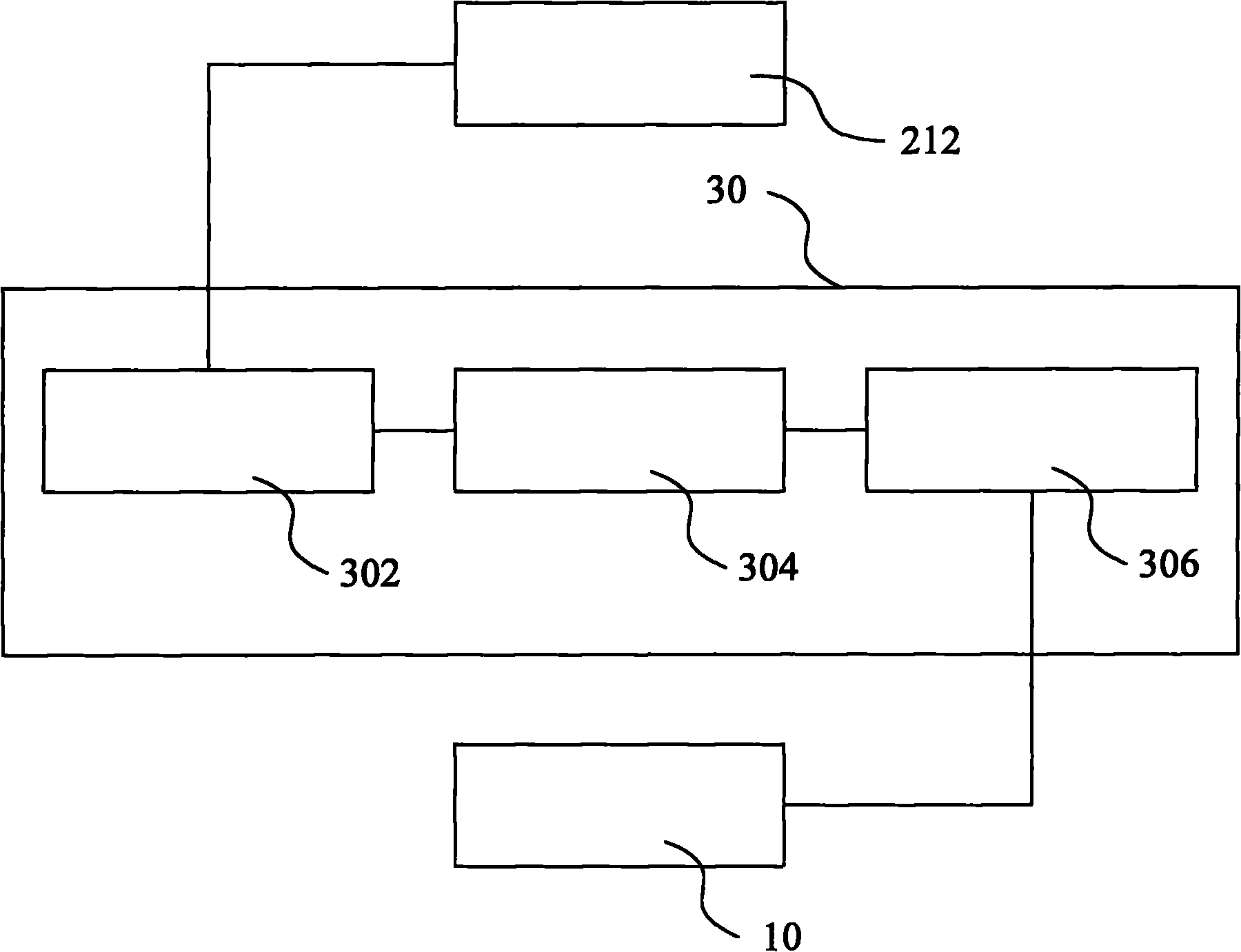

[0027] Such as figure 2 As shown, one embodiment of the grinding device for the shallow trench isolation structure of the present invention includes a grinding part 10 , a monitoring part 20 and a control part 30 . The grinding part 10 is used for grinding the shallow trench isolation structure on the wafer 40, that is, grinding the second SiO formed on the surface of the SiN layer 806 2 Layer 810. The monitoring part 20 is used to monitor the grinding surface of the wafer 40 and feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com