Five-freedom shoemaking automatically grinding glue-spraying processing device

A technology of processing device and degree of freedom, applied in the direction of shoemaking machinery, footwear, shoe soles, etc., can solve the problems of physical hazards of operating workers, low work efficiency, unstable quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] The present invention includes a moving mechanism and a rotating mechanism;

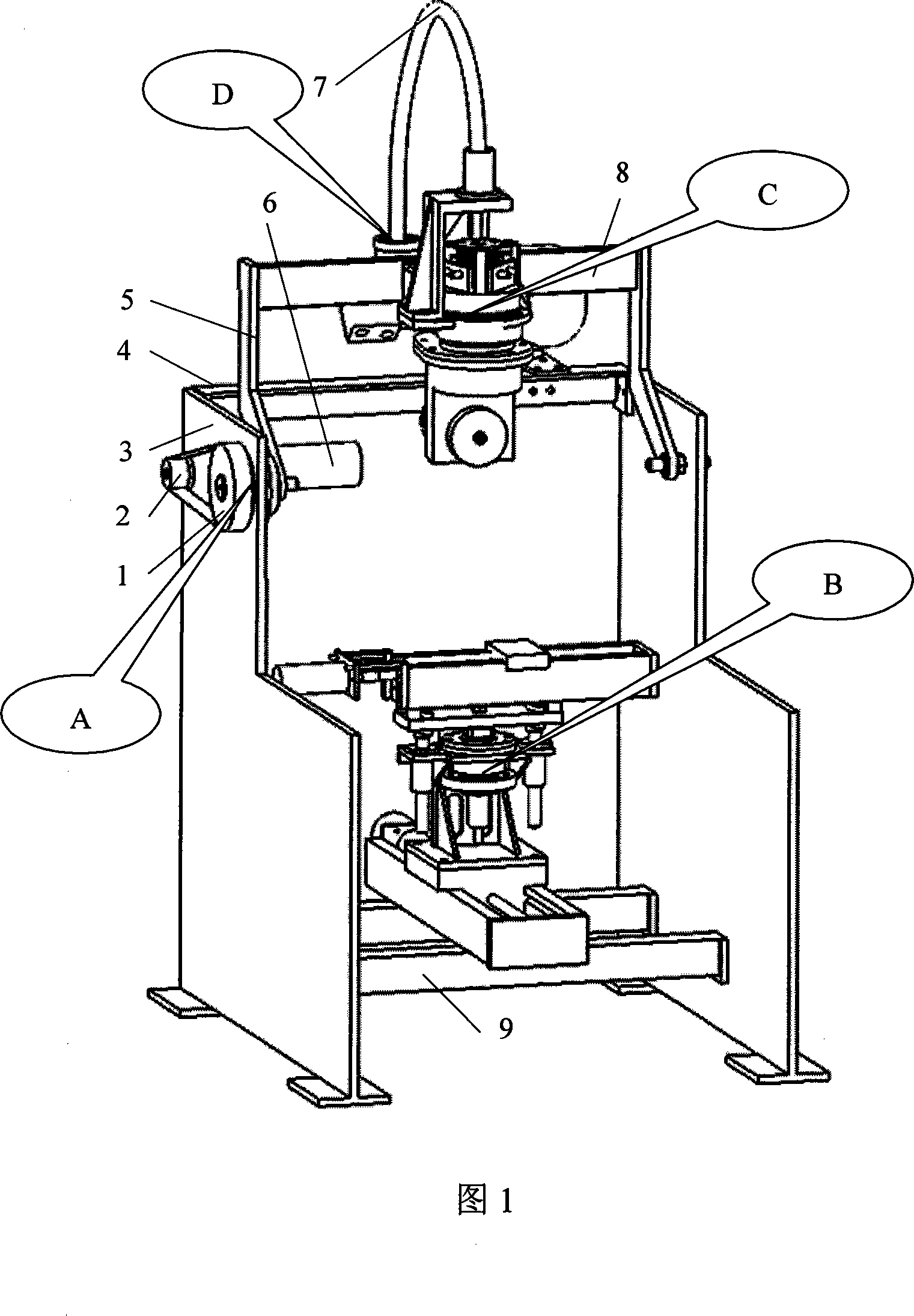

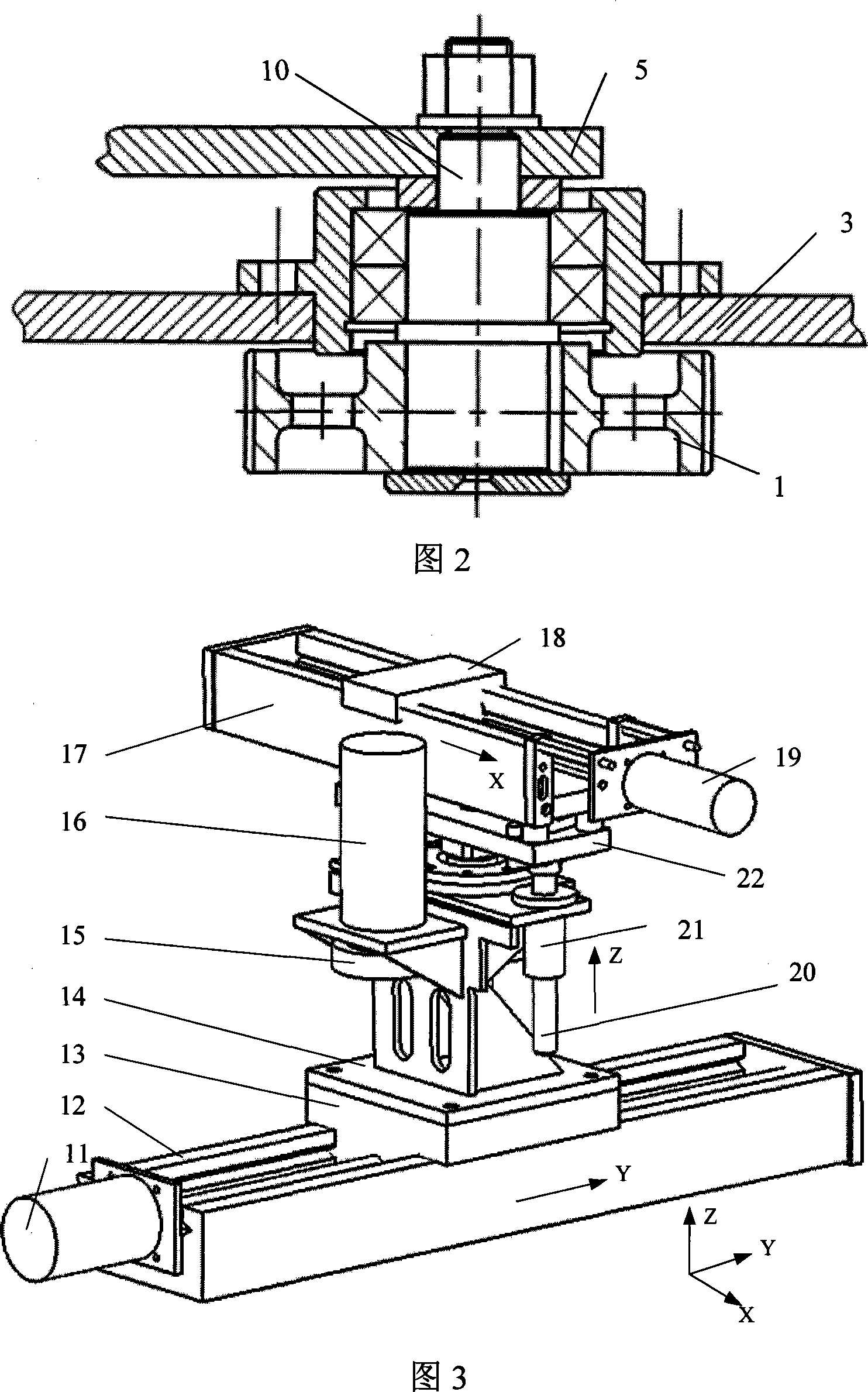

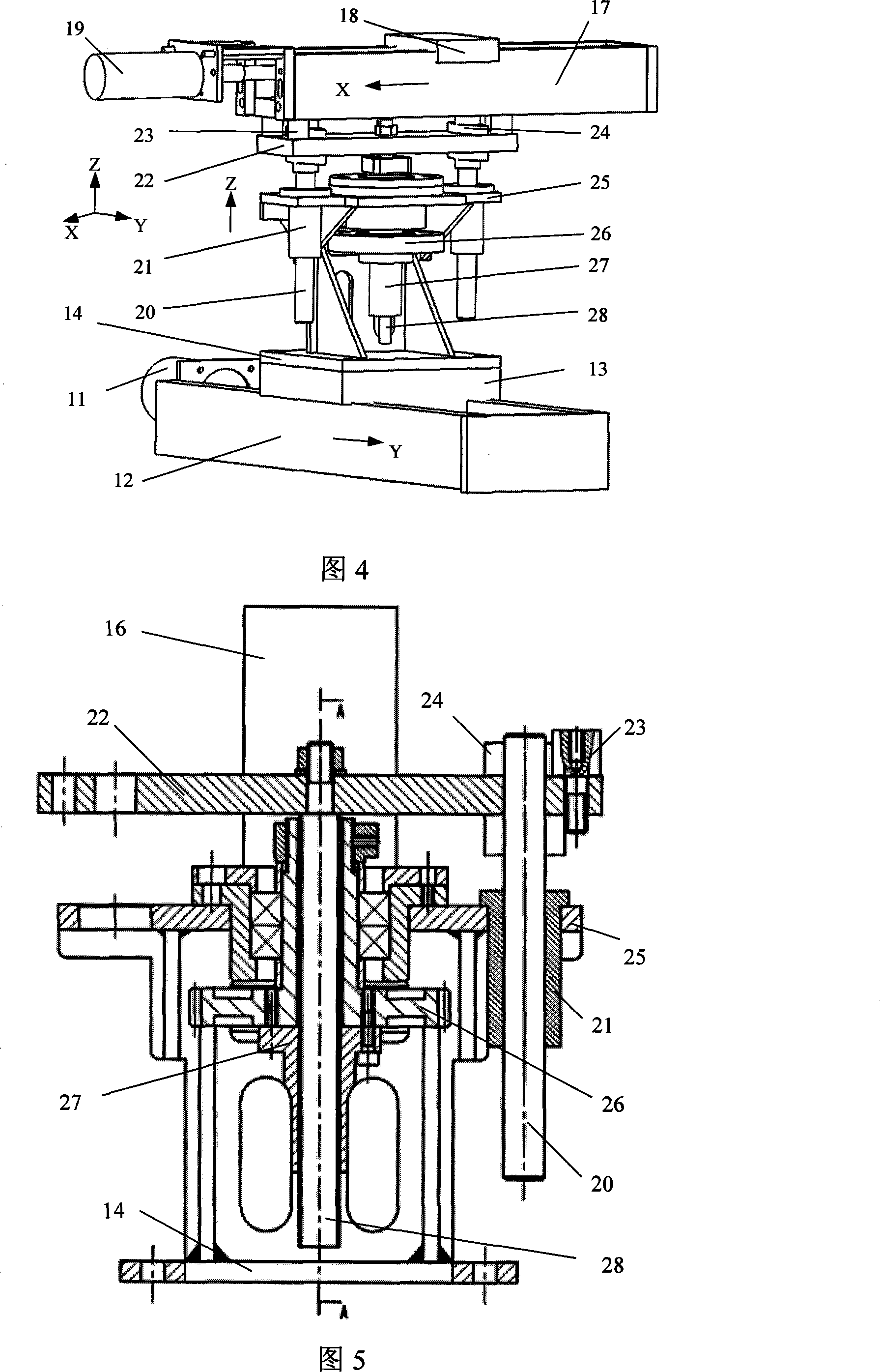

[0027] As shown in Fig. 1, Fig. 3, Fig. 4, Fig. 5, and Fig. 6, the moving mechanism includes three sets of transmission mechanisms for moving in the X, Y, and Z directions, and the transmission mechanism for moving in the Y direction is composed of a set of screw sliders. The first ball screw assembly 12 is installed on the frame through the support assembly 9, and the first group of lead screws is driven by the first AC servo motor 11, so as to be installed on the slider 13 of the first ball screw assembly 12 The movement of the mechanism in the Y direction; the transmission mechanism for the movement in the Z direction is composed of a pair of gear pairs consisting of large and small gears 26, 15 and a screw pair transmission composed of a nut 27 and a screw rod 28. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com