Precision machining apparatus and precision machining method

一种精密加工、设备的技术,应用在金属加工设备、金属加工、磨削/抛光设备等方向,能够解决微小调整不够等问题,达到经济制造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In the following description and drawings, the invention will be described in more detail by way of exemplary embodiments. Pneumatic actuators are used in the illustrated exemplary embodiment. Alternatively, however, hydraulic actuators may be used. In addition, three or more actuators may be provided depending on the pressure control. Furthermore, in the illustrated exemplary embodiment, the pose control means is subject to feedback control. Of course, alternatively, the lead screw mechanism may be subject to feedback control or both the pose control device and the lead screw mechanism are controlled through the interface circuit.

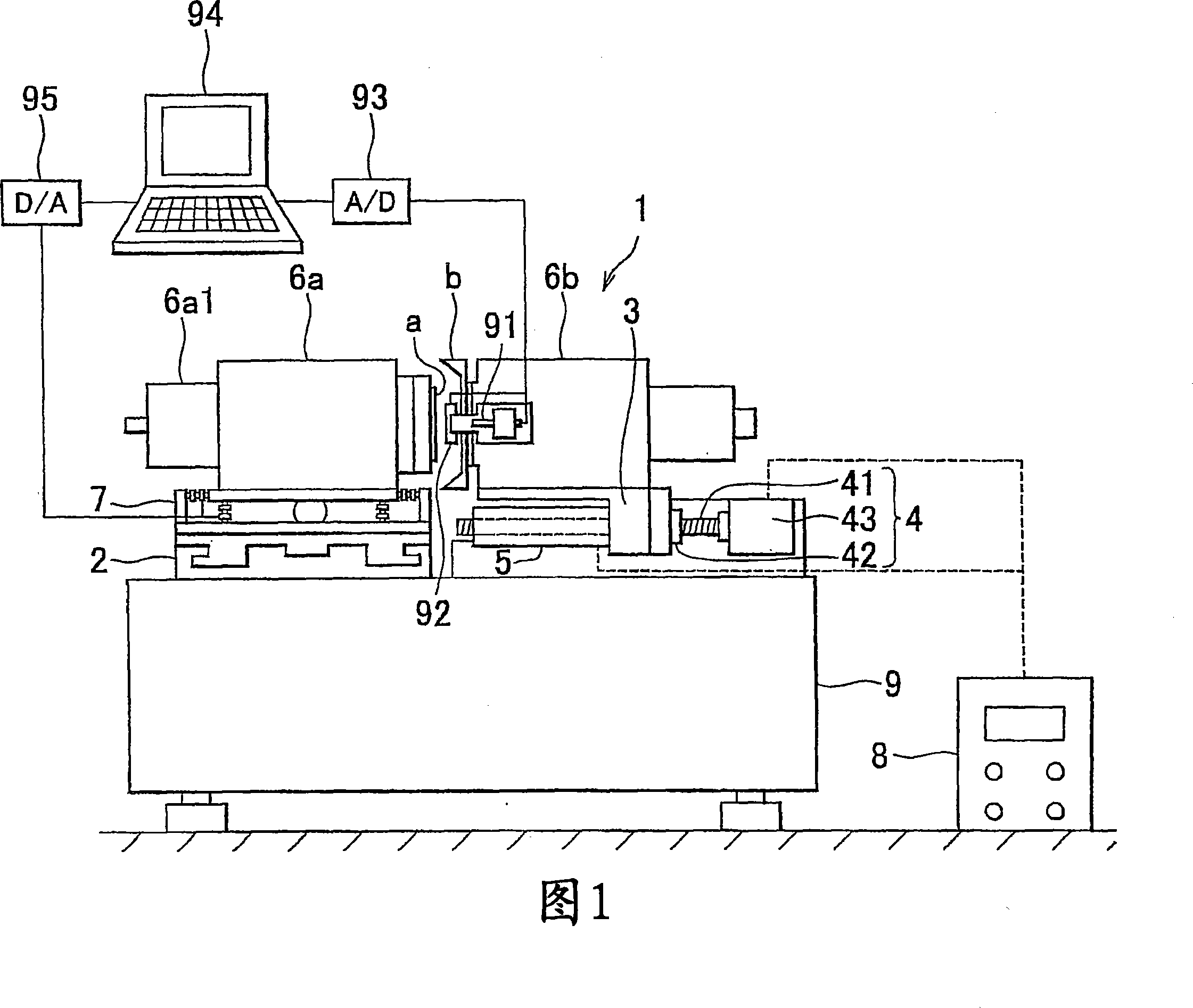

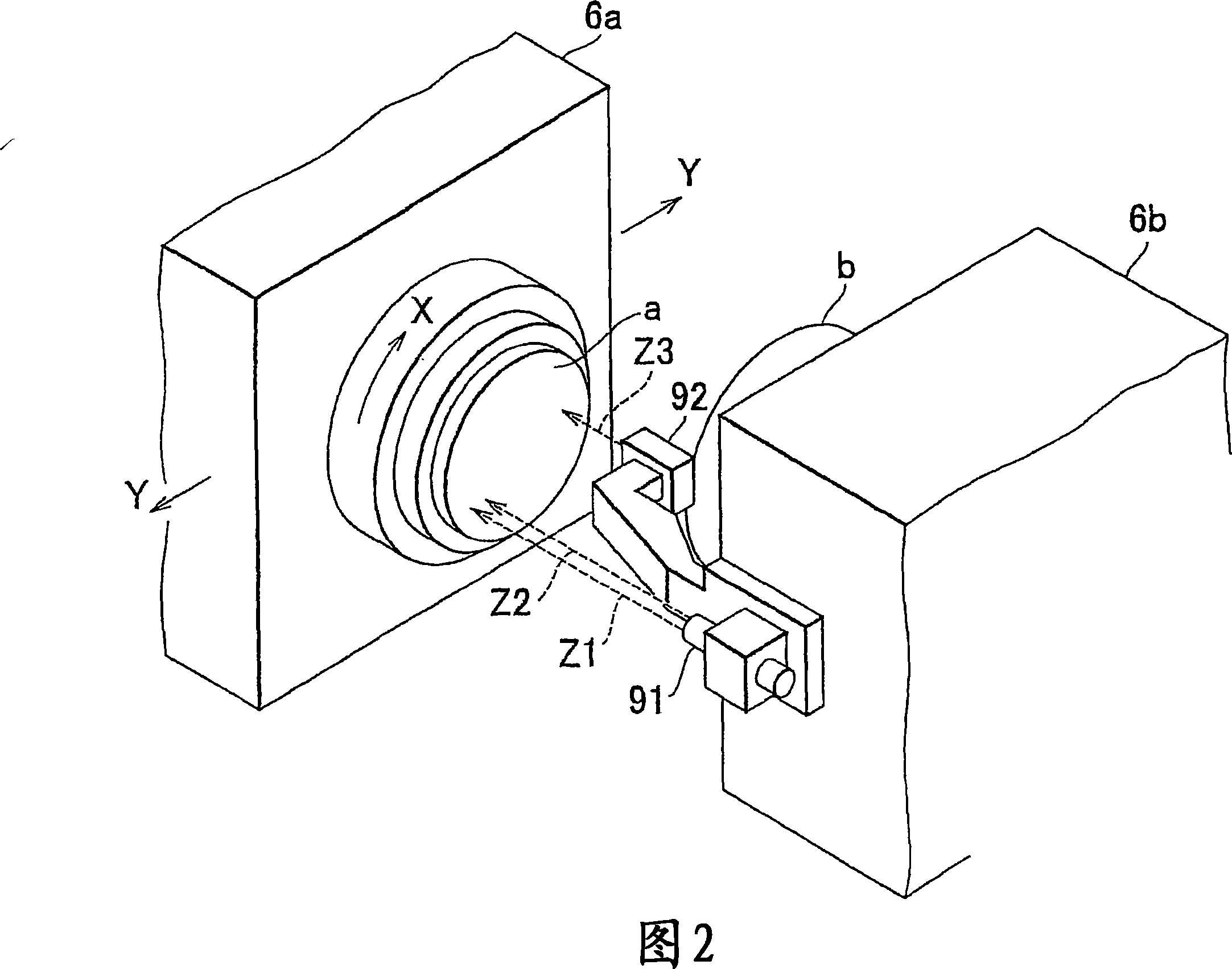

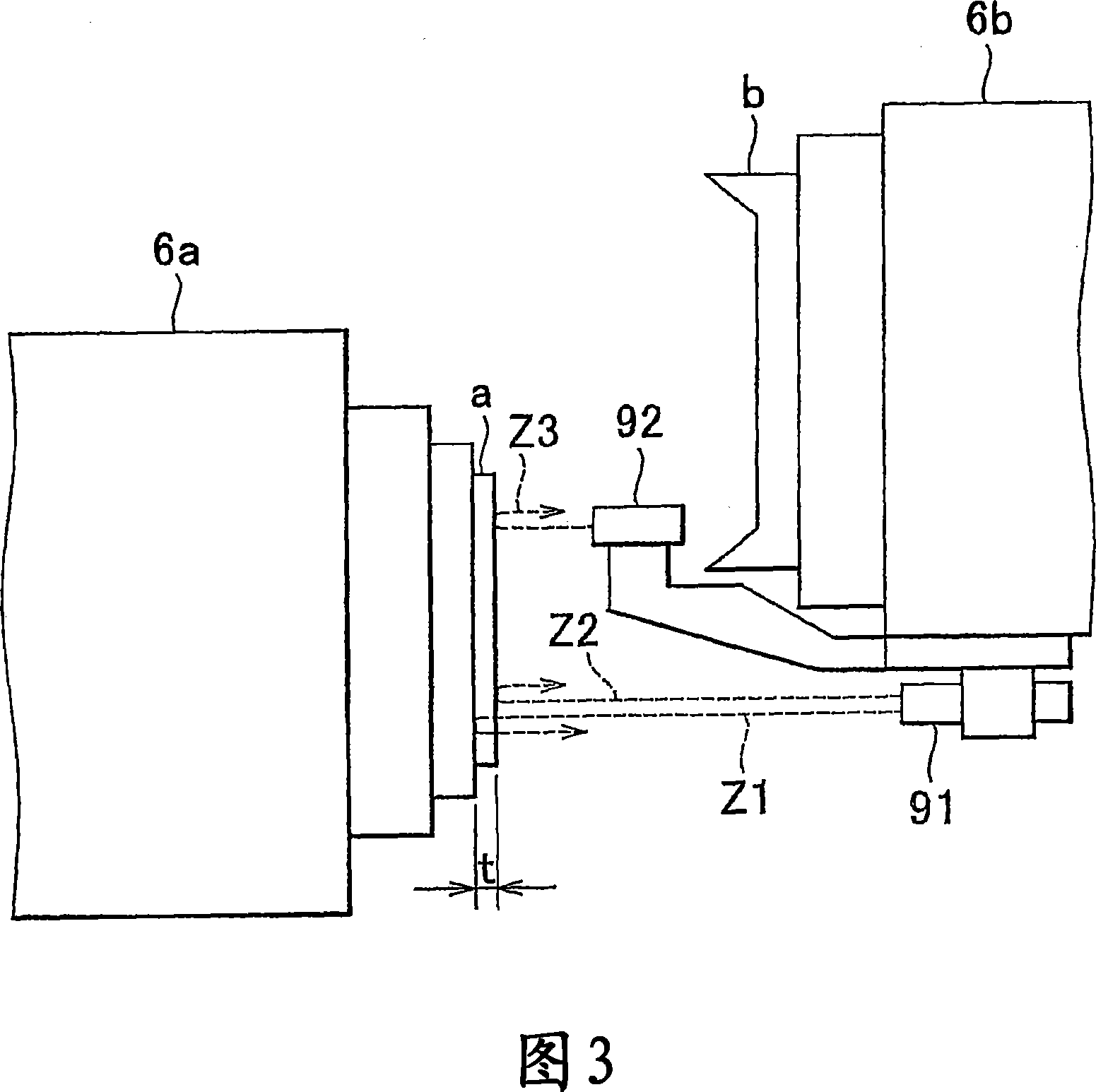

[0056] Fig. 1 shows a precision machining device 1 according to an exemplary embodiment. The precision machining equipment 1 roughly includes: a rotating device 6a that rotates a grinding target a in a vacuum-suction position; a first support 2 that supports the rotating device 6a; and a second support 3 that supports the rotation of a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com