Workpiece automatic machining system and grinding method of surface of workpiece

A processing system and automatic processing technology, applied in the field of machinery, can solve the problems of wasteful labor intensity, insufficient uniformity of precision, and insufficient consistency, and achieve the effect of maintaining consistent processing accuracy, high accuracy and integrity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

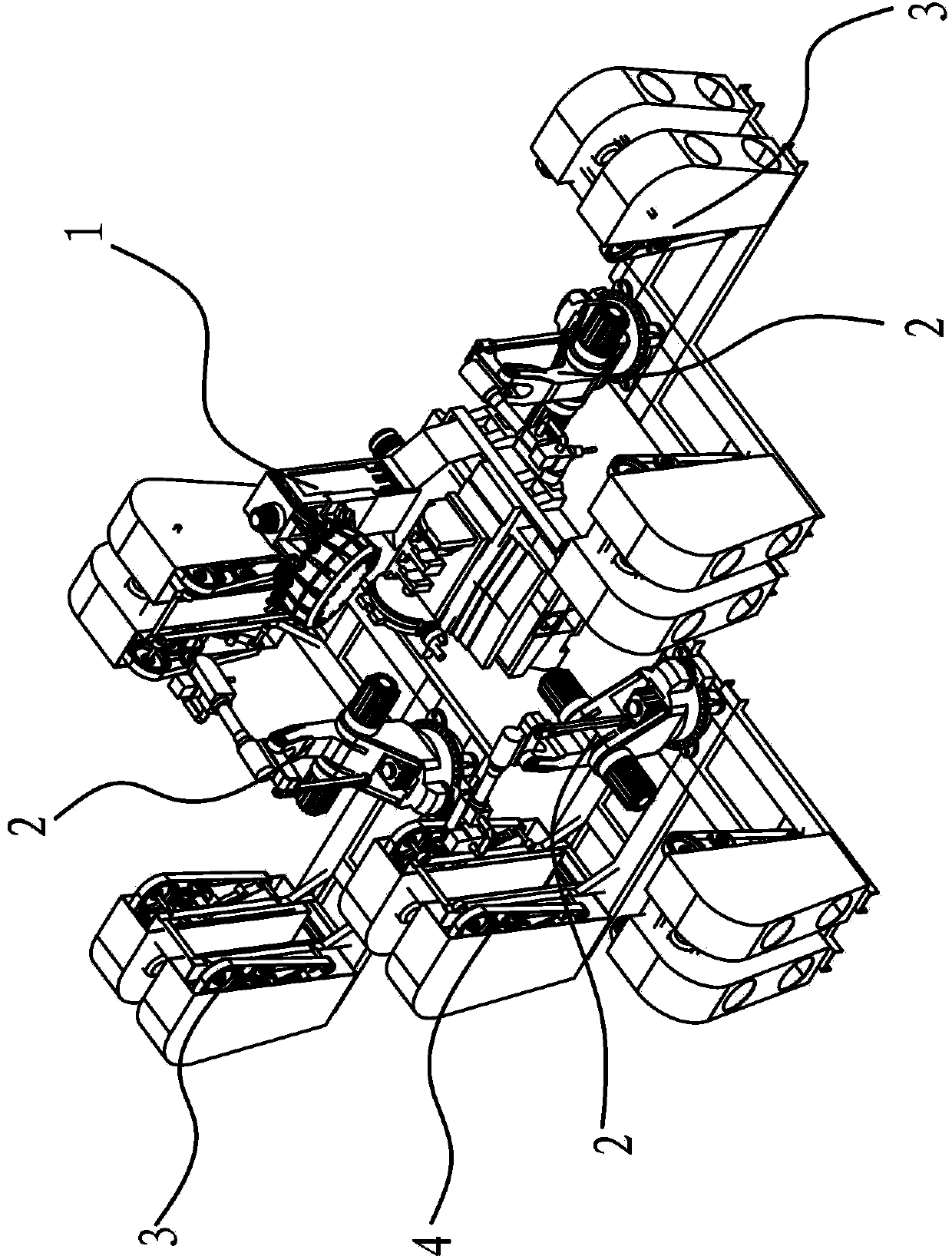

[0041] like figure 1 As shown, a workpiece automatic processing system includes a machining center 1 for machining the workpiece, the machining system also includes a grinding unit adjacent to the machining center 1, and the number of grinding units is 3 and is evenly distributed in the processing Around the center 1, there is also a storage hopper for placing the processed workpiece around each grinding unit. The grinding unit is provided with a manipulator 2 and several grinding machines 3 , and each grinding unit has four grinding machines 3 .

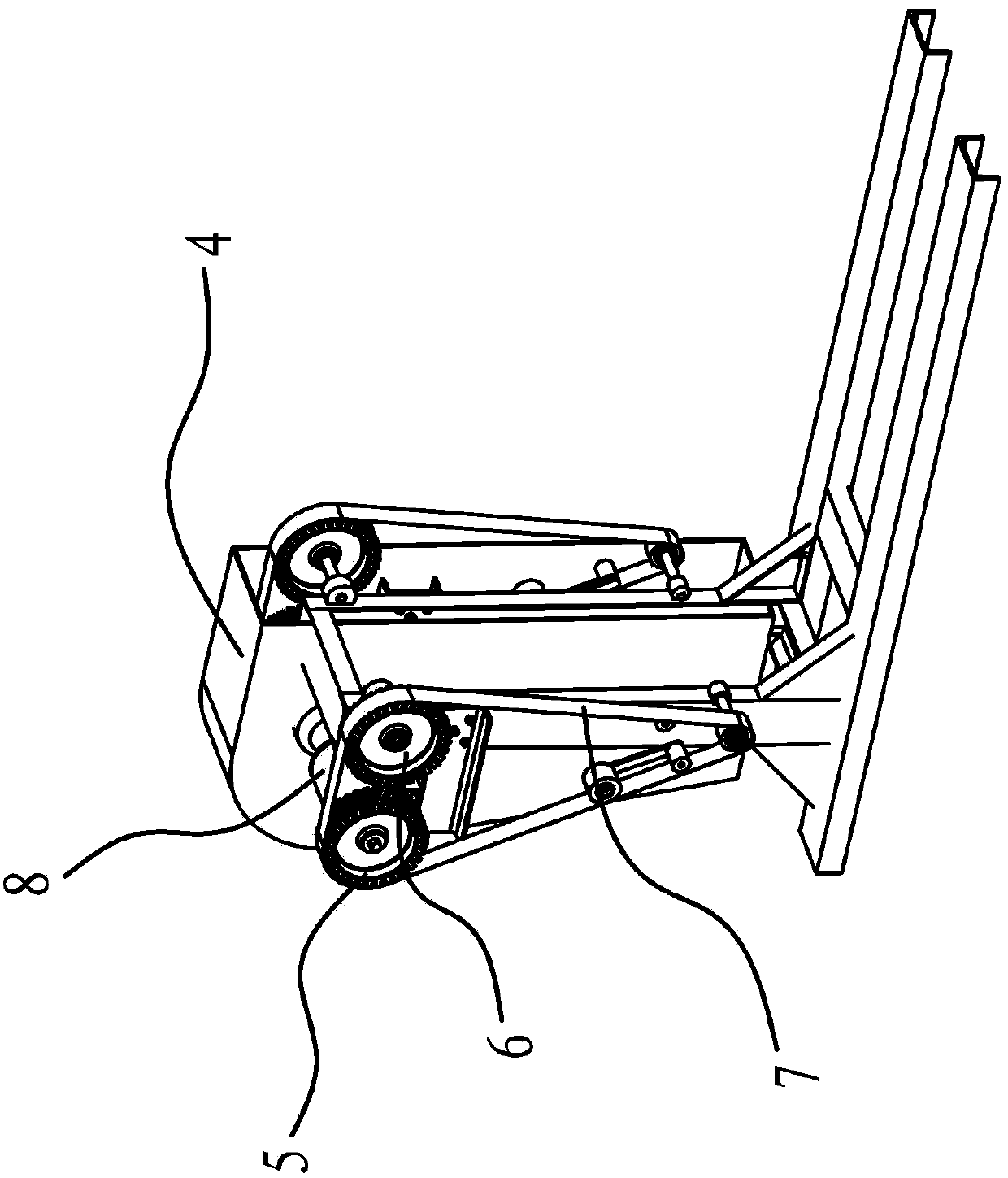

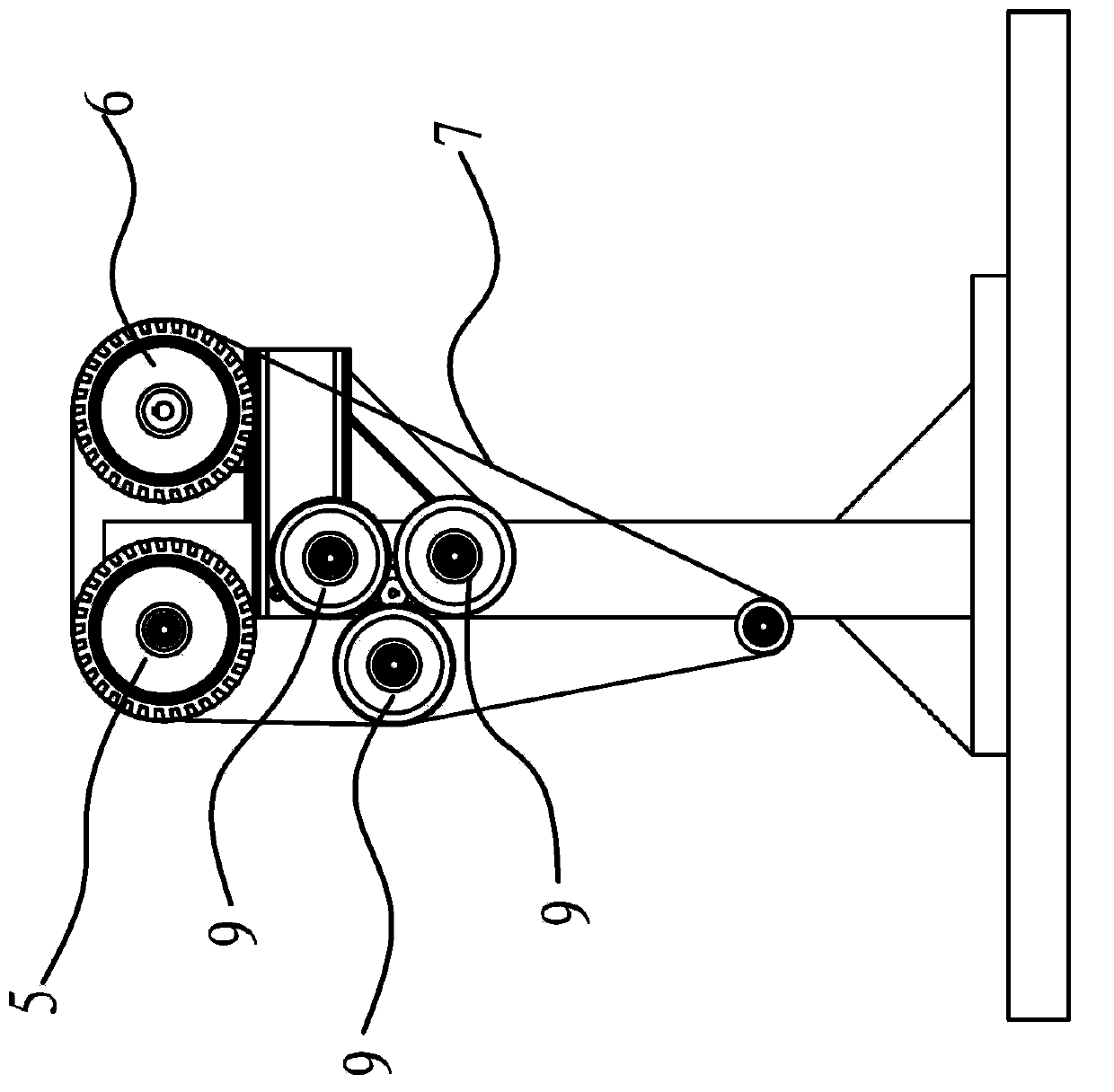

[0042] like Figure 4 As shown, the manipulator 2 can clamp and transport the machined workpiece at the machining center 1 to any grinding machine 3 . The manipulator 2 includes a base 10, a clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com