Building material surface coating equipment

A building material surface and coating technology, applied in related fields, can solve the problems of uneven surface and time-wasting of building material spraying, and achieve the effect of rapid polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

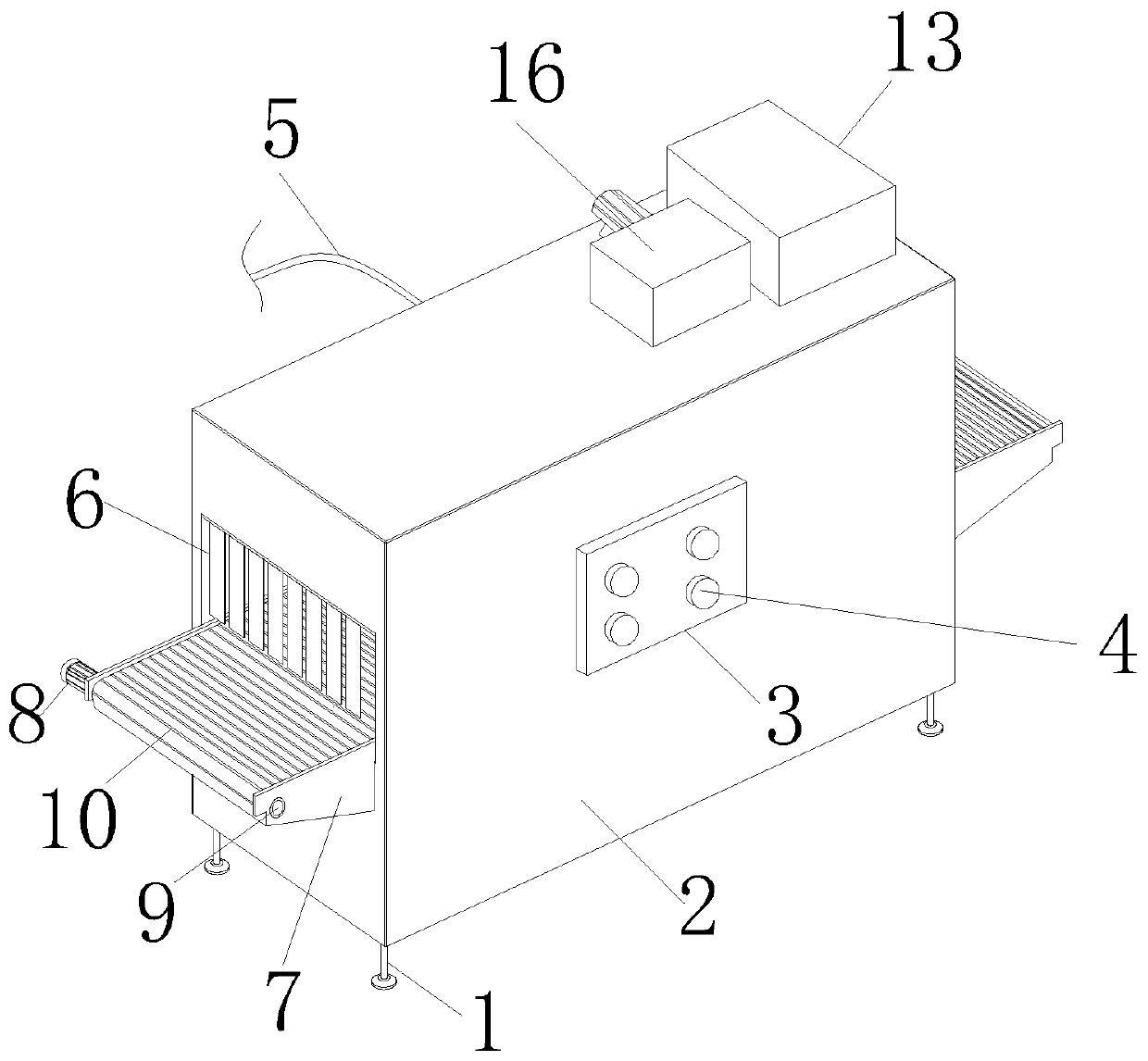

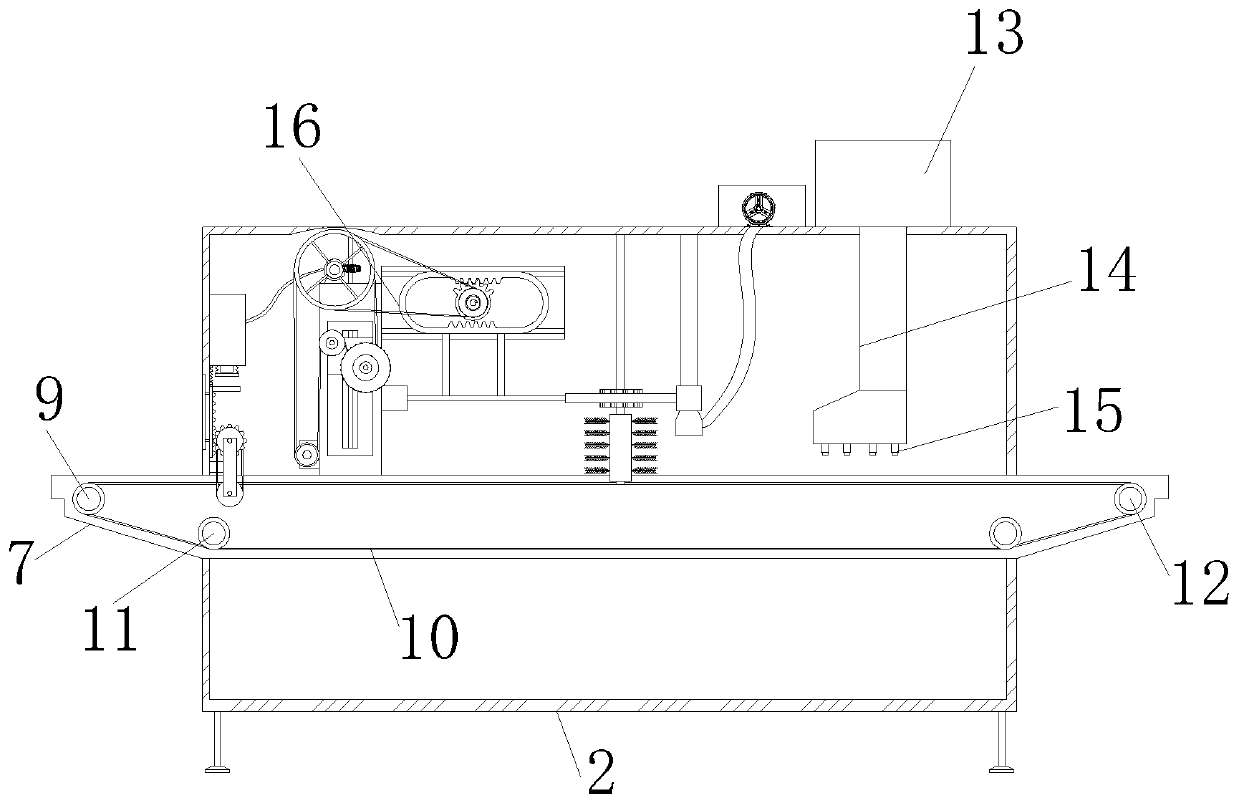

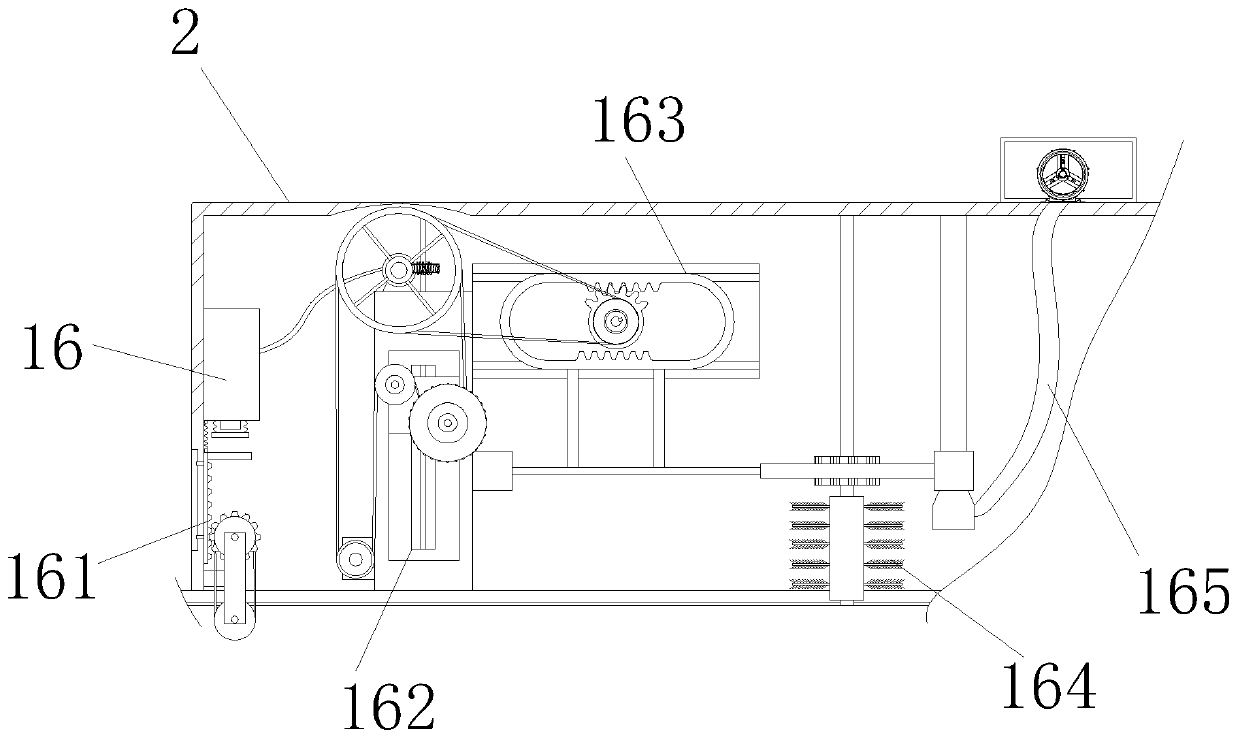

[0036] The present invention provides a coating device for the surface of building materials through improvement, including a support foot 1, a conduit 14, a spray nozzle 15 and a polishing and cleaning device 16. The support foot 1 is fixedly connected to the four corners of the bottom of the frame body 2, and the right end of the frame body 2 is provided with a Control panel 3, button 4 is installed on the front end of control panel 3, power wire 5 is fixed on the rear end of frame body 2, protective strips 6 are equidistantly distributed at the middle opening of the front end of frame body 2, and bolts at the front and rear ends of frame body 2 and support plate 7 Connection, the support plate 7 is locked and fixed with the front end of the first motor 8 by screws, the output end of the first motor 8 is connected to the middle of the driving roller 9 in rotation, and the driving roller 9 is connected to the inner side wall of the directional wheel 11 and the driven roller 12 ...

Embodiment 2

[0049] The present invention provides a coating device for the surface of building materials through improvement, the second pulley 1627 and the third pulley 1628 have the same size, and the second pulley 1627 and the third pulley 1628 are along the upper left side and the lower right end of the front end of the sliding plate 1629 The lower end of the guide frame 1634 is provided with a chute 1639, the receiving rod 1635 slides along the inner wall of the chute 1639, and the upper and lower sides of the track frame 1633 are provided with tooth angles 16310, and the tooth angles 16310 are equidistantly distributed along the upper and lower sides of the track frame 1633, and the section of the front end of the suction head 1653 is trapezoidal.

[0050] The present invention provides a kind of coating equipment of building material surface through improvement, and its working principle is as follows;

[0051] First, before use, place the coating equipment on the surface of the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com