High-end device for polishing two surfaces of PCB

A PCB board, two-sided technology, applied in the field of high-end devices, can solve the problem of resin not being polished cleanly, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

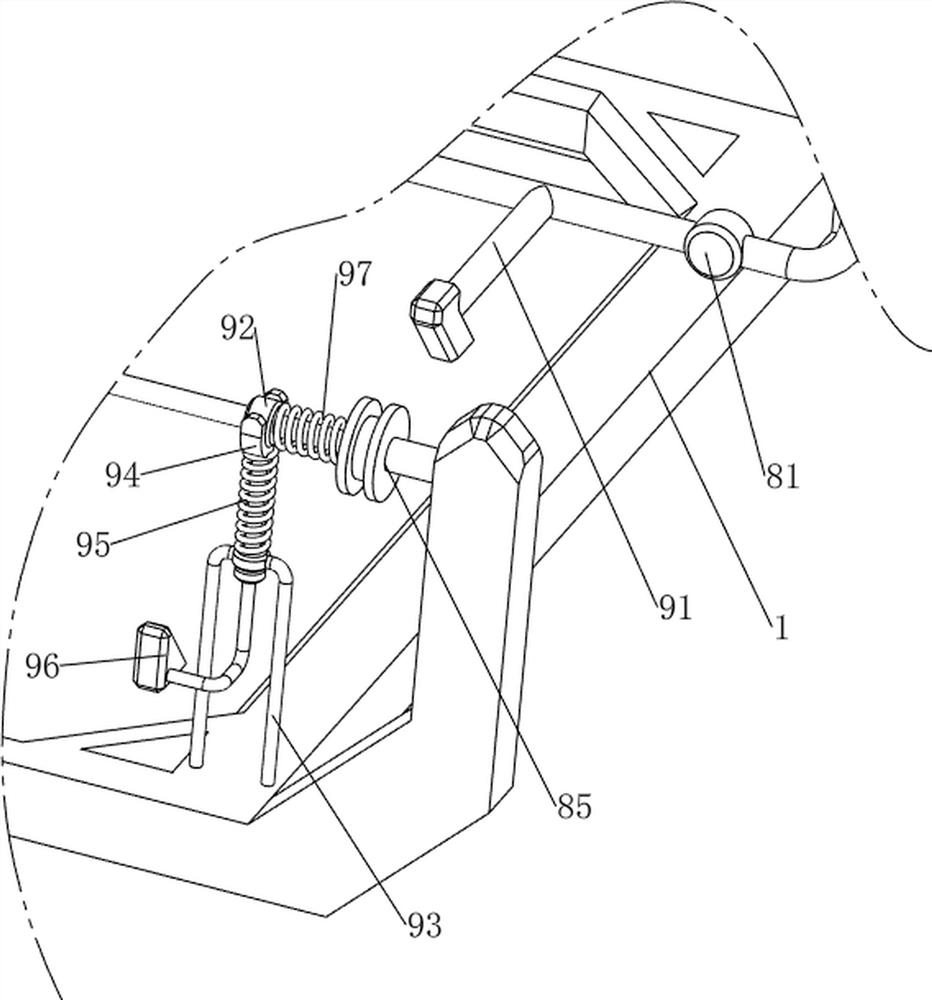

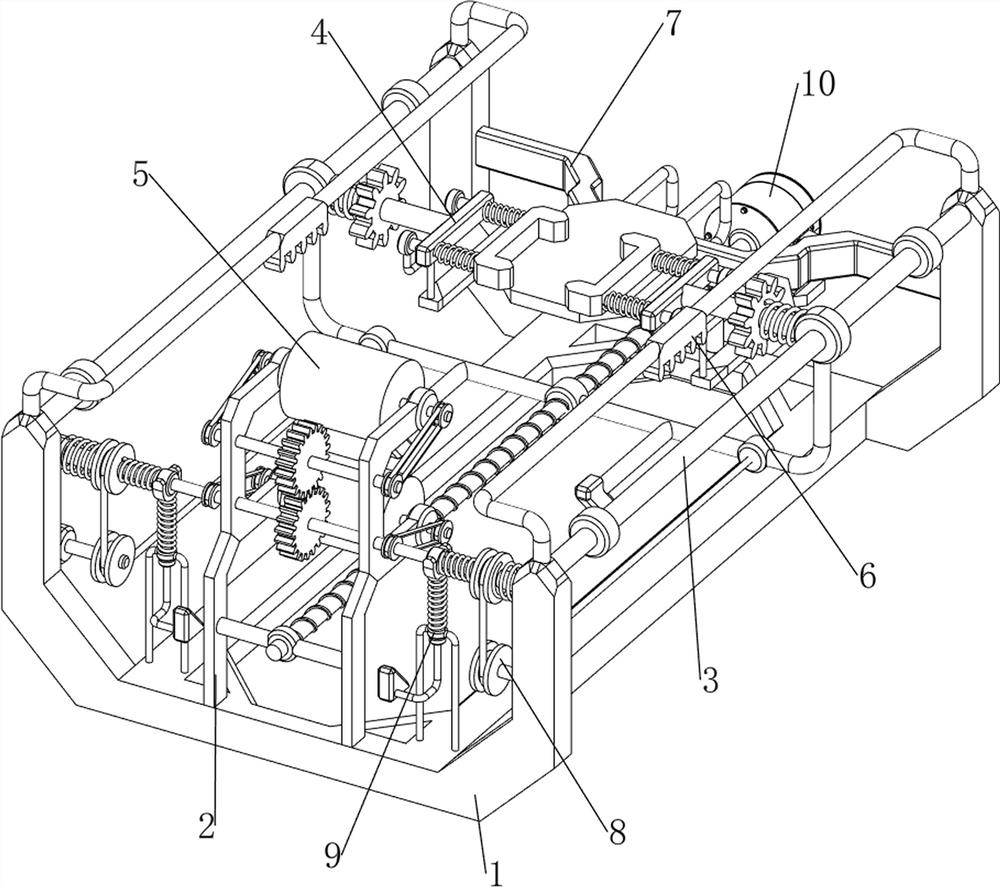

[0068] A high-end device for polishing both sides of the PCB board, such as figure 1 As shown, it includes a base plate 1, a fixed frame 2, a first slide rail 3, a clamping mechanism 4, and a grinding mechanism 5. The upper and front sides of the base plate 1 are symmetrically provided with a fixed frame 2, and the base plate 1 is provided with a first slide rail 3. A clamping mechanism 4 is slidably connected between the two first slide rails 3 , a grinding mechanism 5 is connected between the two fixed frames 2 , and the clamping mechanism 4 cooperates with the grinding mechanism 5 .

[0069] When it is necessary to polish both sides of the PCB board, the worker will clamp the PCB board through the clamping mechanism 4, and the worker pushes the clamping mechanism 4 to move in the first slide rail 3, thereby driving the PCB board to move to contact with the grinding mechanism 5, and to grind Mechanism 5 will polish the two sides of the PCB board, and the worker repeats the a...

Embodiment 2

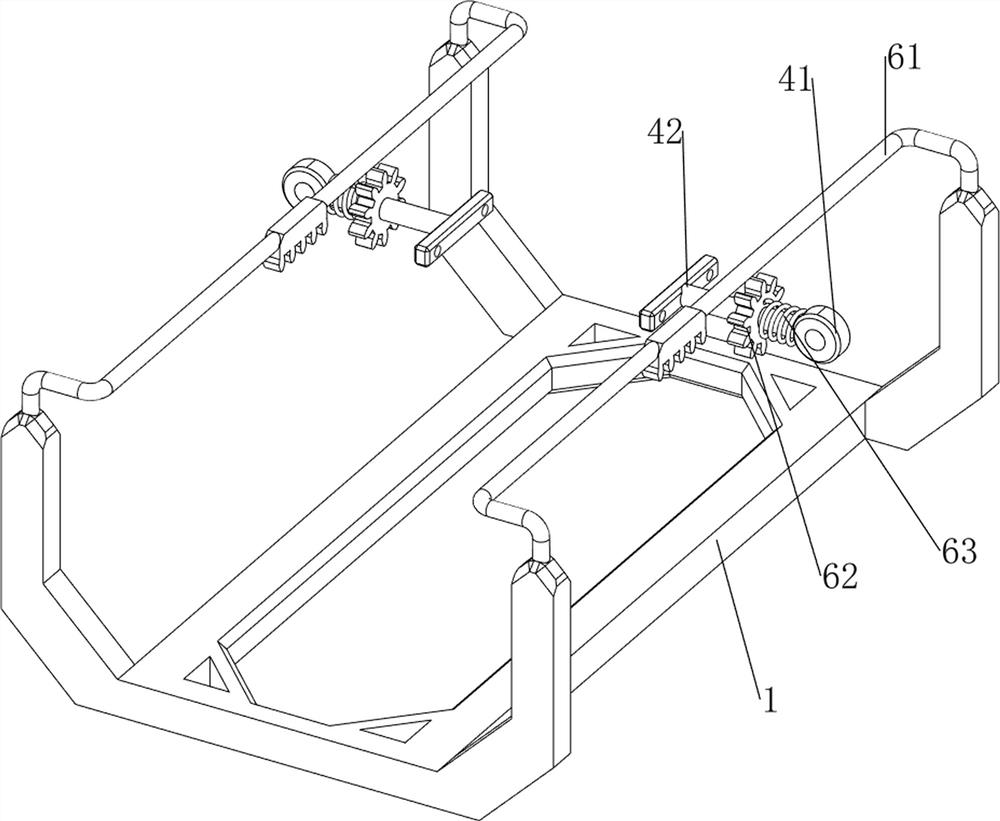

[0071] In a preferred embodiment of the present invention, as Figure 1-Figure 8 As shown, the clamping mechanism 4 includes a first slider 41, a first support frame 42, a clamp 43 and a first spring 44, and the first slider 41 is slidably provided on the two first slide rails 3, and the two pieces The first slide block 41 is equipped with a first support frame 42 in a rotating manner, and the two first support frames 42 are slidably provided with a clamp 43, and the two clamps 43 are equipped with a first spring 44. Both ends of the spring 44 are respectively connected to the first supporting frame 42 and the clamp 43 .

[0072] When the PCB board needs to be clamped, the worker holds the clamp 43, pulls the two clamps 43 to move outward, the first spring 44 is compressed, and when the gap between the two clamps 43 is large, the worker puts the PCB board. When entering between the two clamps 43, the worker loosens the clamps 43 to reset the first spring 44, thereby driving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com