Polishing device for round glass of mahjong table

A mahjong table and glass technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of glass residue cleaning, low work efficiency, unstable grinding method, etc., to prevent scratches , Improve work efficiency and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

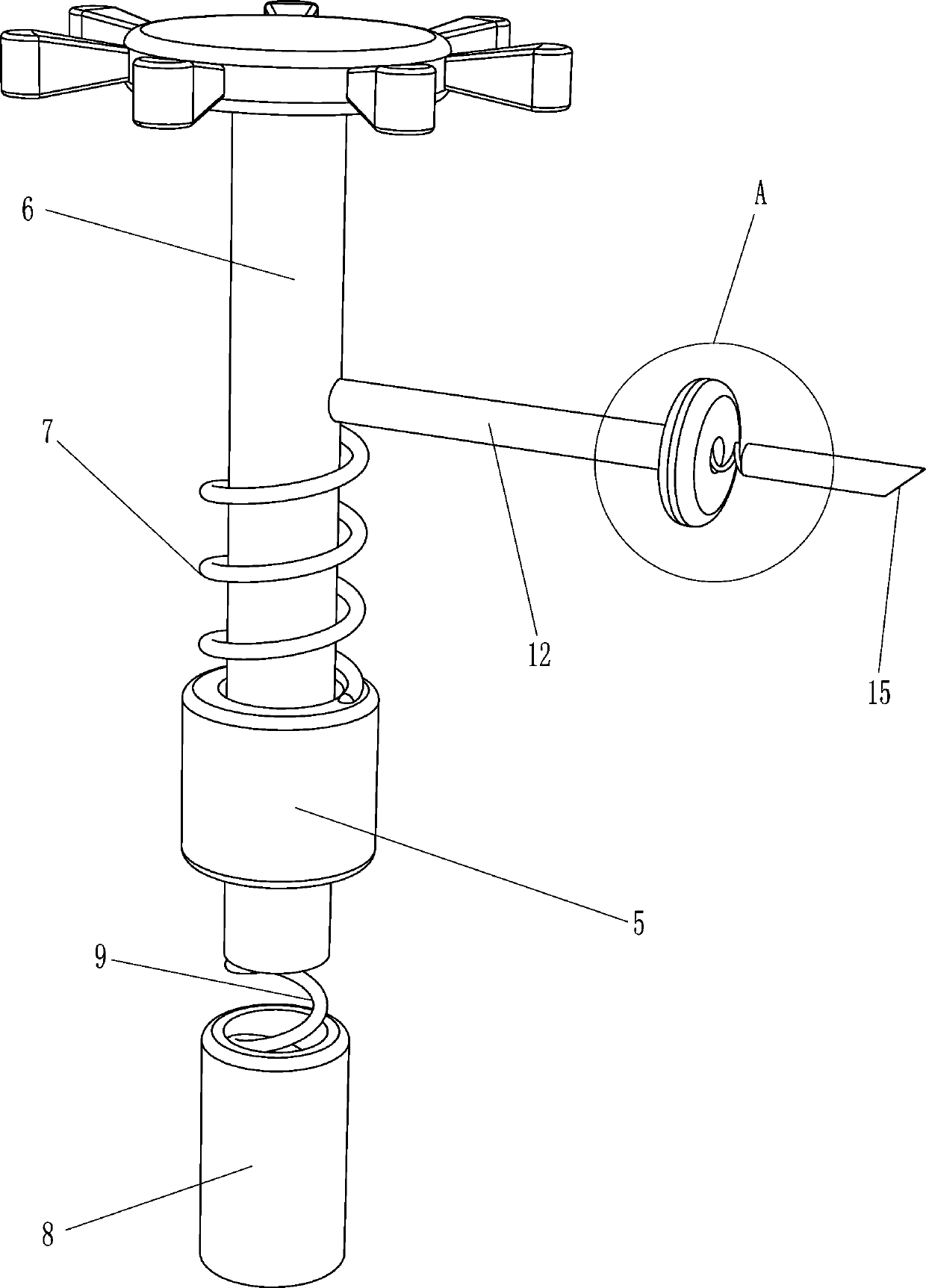

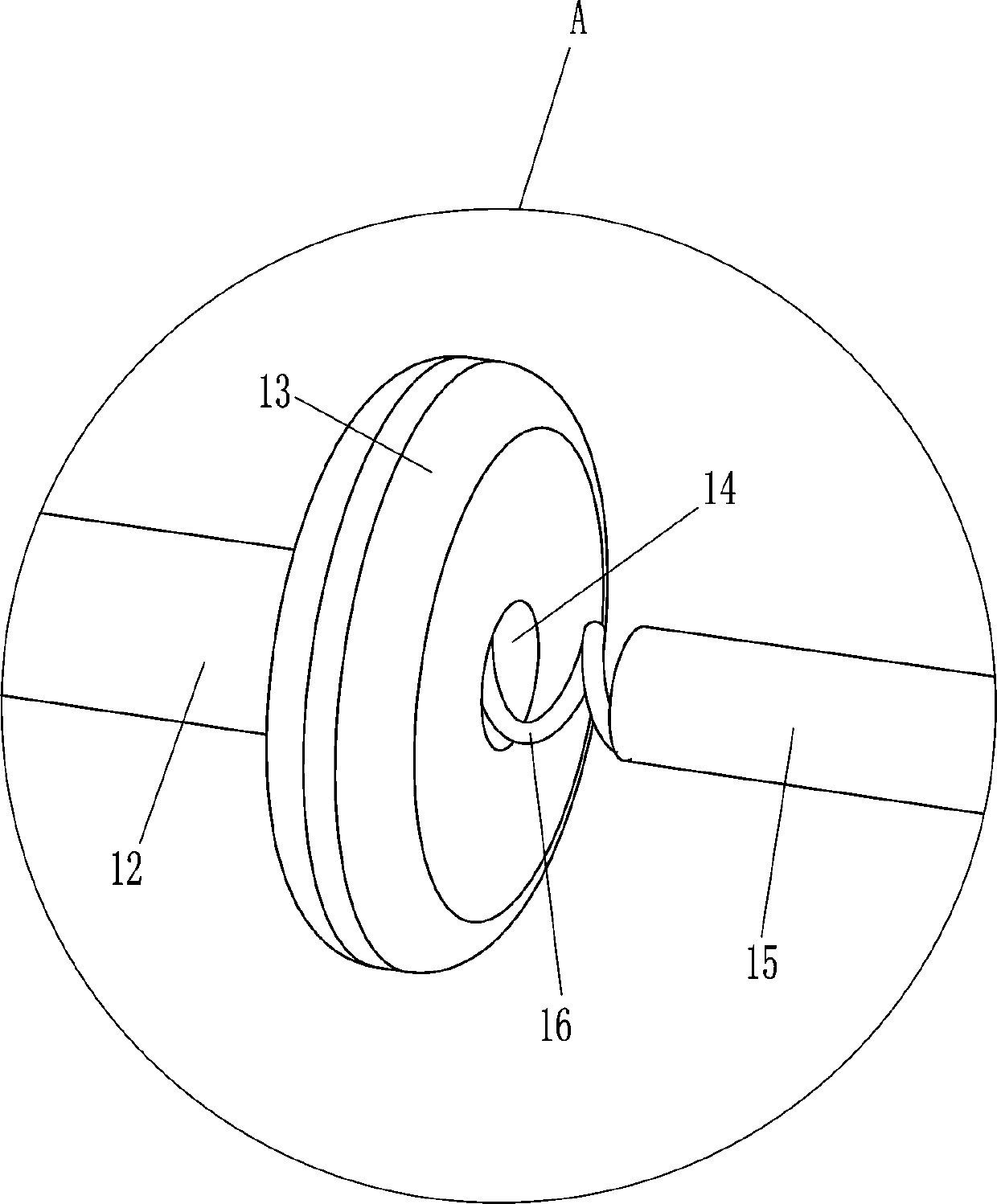

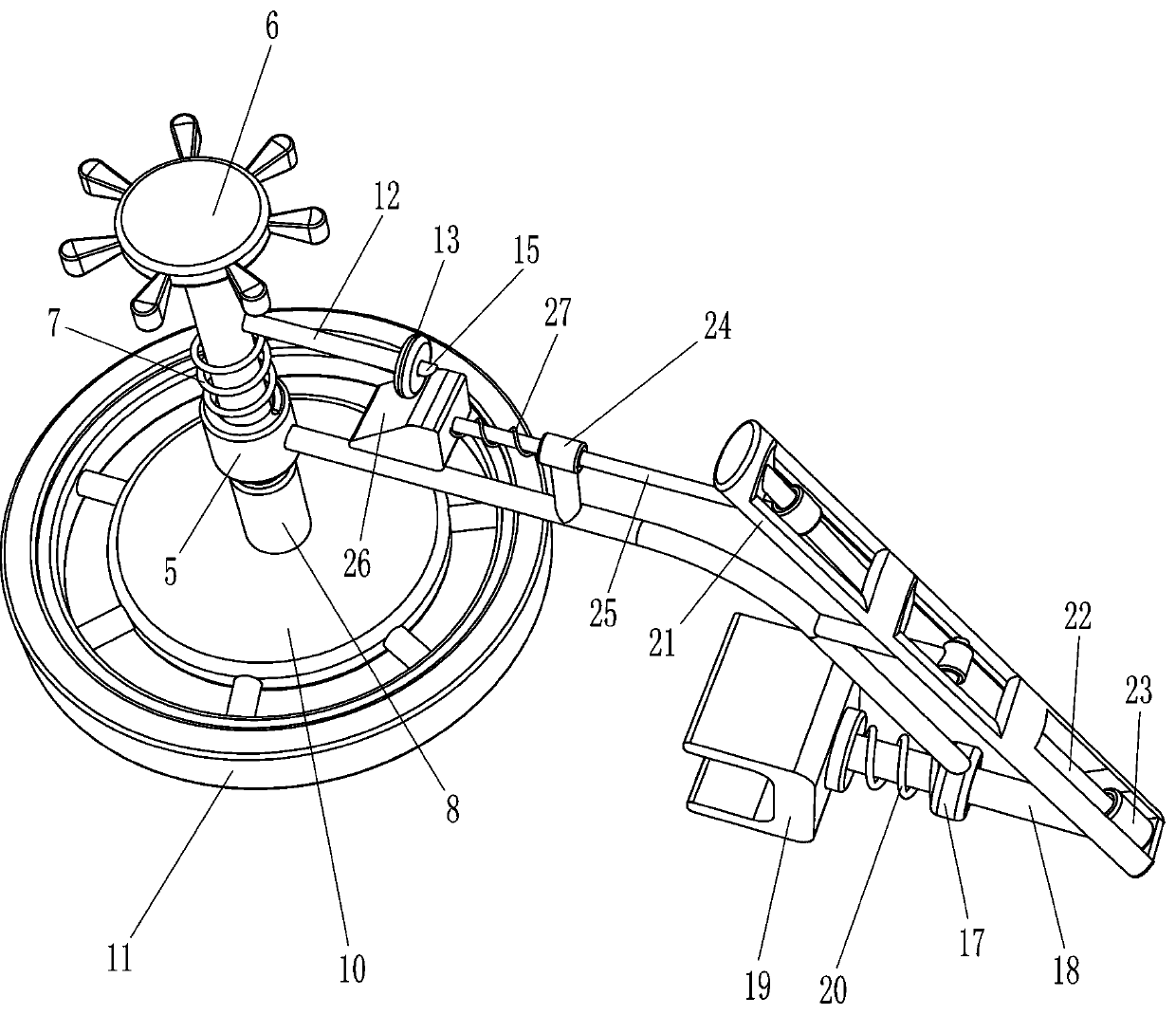

[0020] A kind of mahjong table circular glass grinding device, such as Figure 1-4 As shown, it includes a mounting frame 1, a motor 2, a placement assembly, a pressing assembly, a clamping assembly, and a grinding assembly. The middle part of the mounting frame 1 is fixed with a motor 2 through bolts, and the motor 2 is provided with an adsorption mechanism. The placement component for fixed placement of glass, the mounting frame 1 is provided with a pressing component that is pressed by sliding, the pressing component is provided with a clamping component that is fixed by sliding, and the mounting frame 1 is equipped with Grinding components for grinding.

[0021] like figure 1 As shown, the placement assembly includes a circular ring 3 and a suction cup 4 , the output shaft of the motor 2 is provided with a circular ring 3 , and a ring of suction cups 4 is evenly spaced on the circular ring 3 .

[0022] like figure 1 and 2 As shown, the pressing assembly includes a firs...

Embodiment 2

[0031] like figure 1 As shown, on the basis of Embodiment 1, in order to collect glass shavings, an annular collection frame 28, a U-shaped brush 29 and a discharge pipe 30 are also included. U-shaped brushes 29 are arranged on the upper left side and the rear side, and a discharge pipe 30 with a valve is arranged on the annular collection frame 28 .

[0032] The working principle of the above-mentioned embodiment: when the circular glass is polished, the scraps of the glass during polishing are swept into the annular collection frame 28 by the U-shaped brush 29, and the glass scraps in the annular collection frame 28 reach a certain amount. , open the valve on the discharge pipe 30, and discharge the glass debris through the discharge pipe 30, so that the glass debris can be collected and cleaned uniformly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com