Aluminium profile door and window frame grinding device

A technology for aluminum profiles and frames, which is applied in the field of grinding devices for aluminum profile door and window frames, which can solve the problems of abrasive belts falling out and troublesome grinding work, and achieve the effect of fast grinding and preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

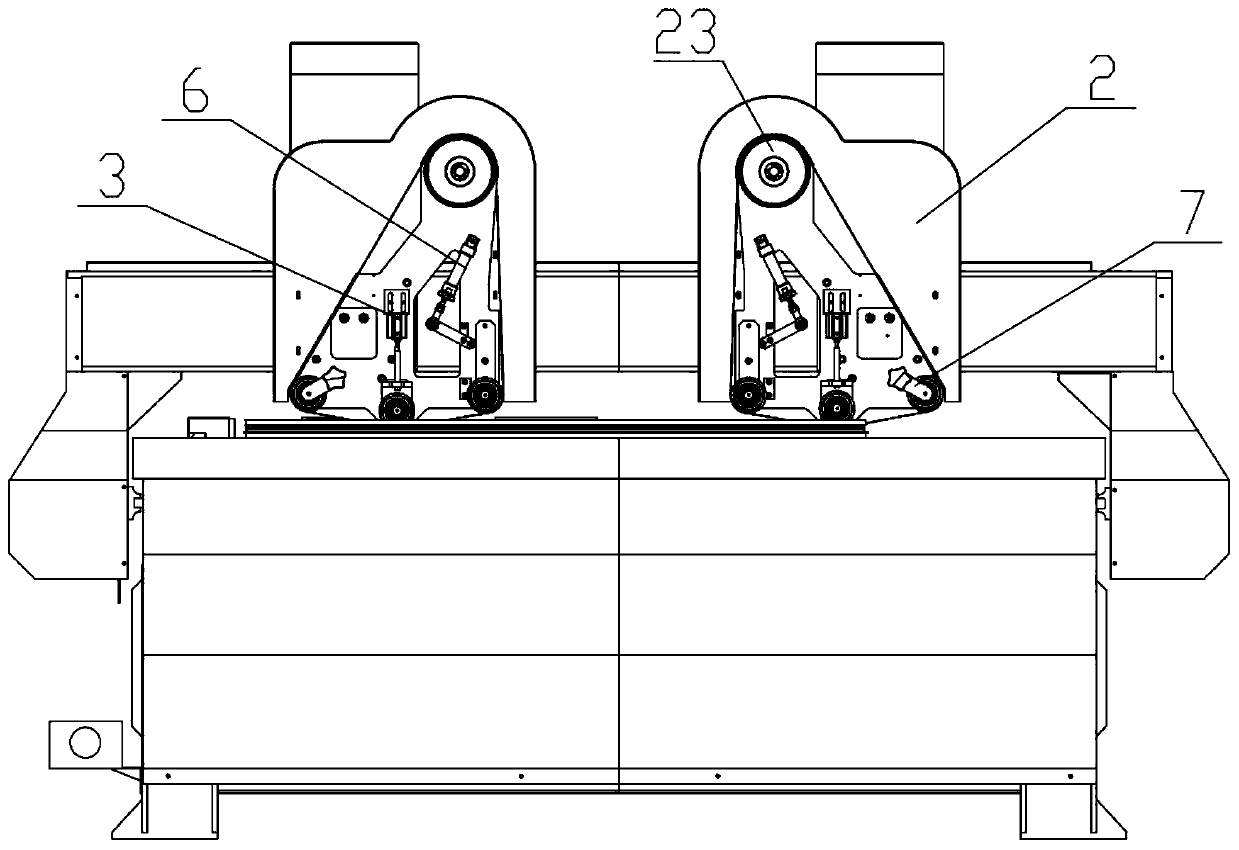

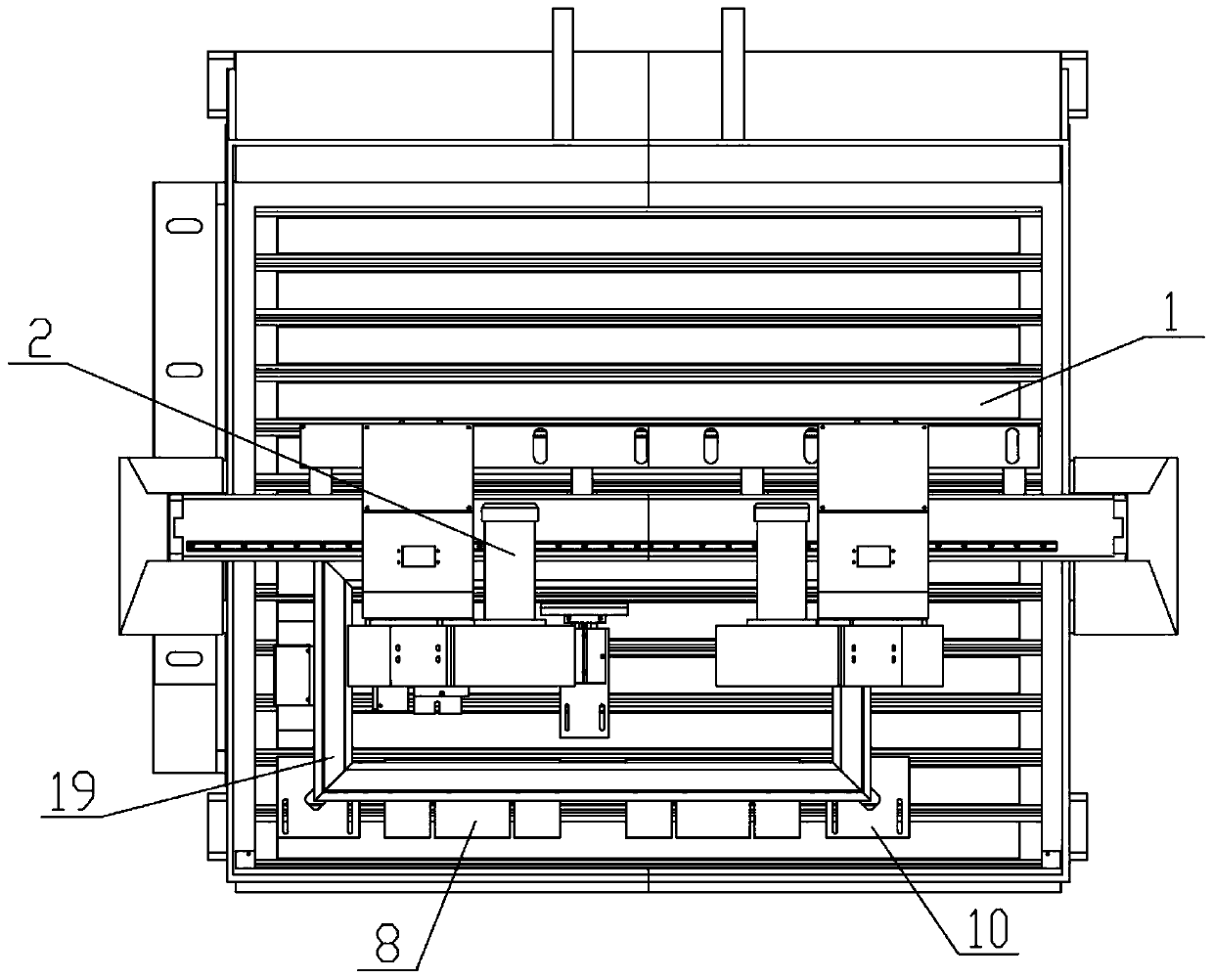

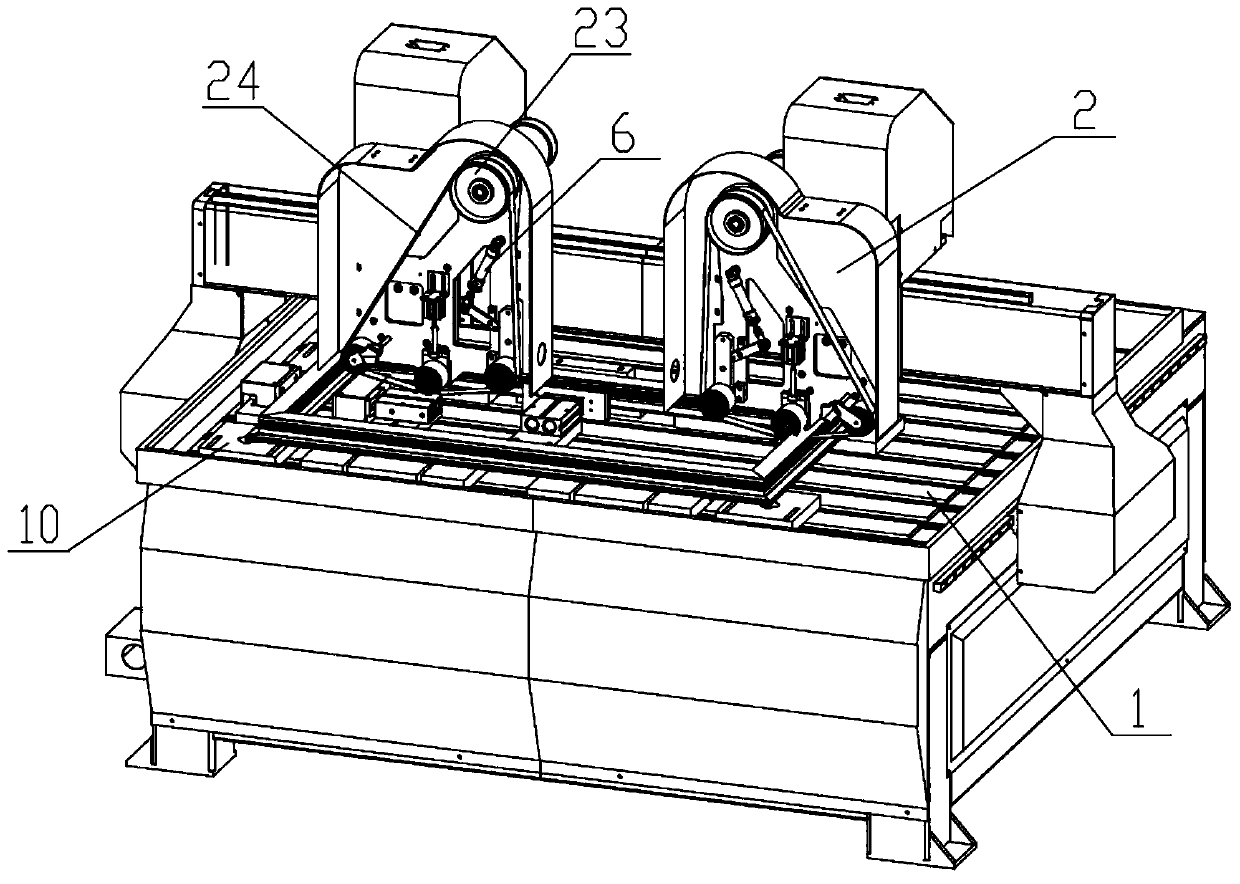

[0032] see Figure 1-Figure 3 As shown, the invention discloses a grinding device for aluminum profile door and window frames, which includes a workbench 1 and at least one set of grinding mechanisms 2 located on the workbench 1 .

[0033] Figure 4-Figure 6 As shown, the grinding mechanism 2 includes a mounting plate 21, a grinding motor 22, a driving wheel 23 and an abrasive belt 24. The grinding motor 22 is located on one side of the mounting plate 21 and is connected to the driving wheel 23 through a flange. Be provided with and be used to press down abrasive belt 24 and then the pinch wheel 25 of polishing frame 19, pinch wheel 25, be provided with the lifting assembly 3 that drives pinch wheel 25 to move up and down to regulate emery belt 24 and frame 19 distance, press Both sides, top of the tension wheel 25 are provided with a first transmission whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com