Hardware inner wall grinding equipment

A technology for hardware and equipment, which is applied in the field of grinding equipment for the inner wall of hardware, can solve the problems of complex operation and cleaning of debris generated during grinding, and achieve the effect of precise and fast grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

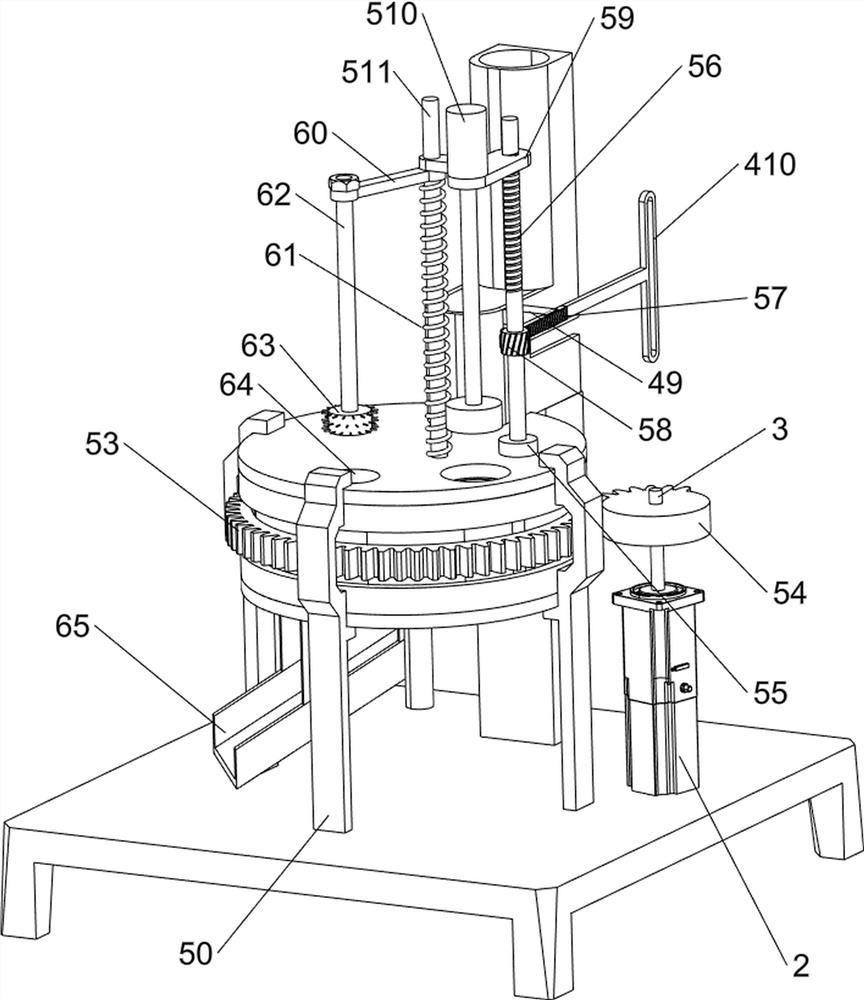

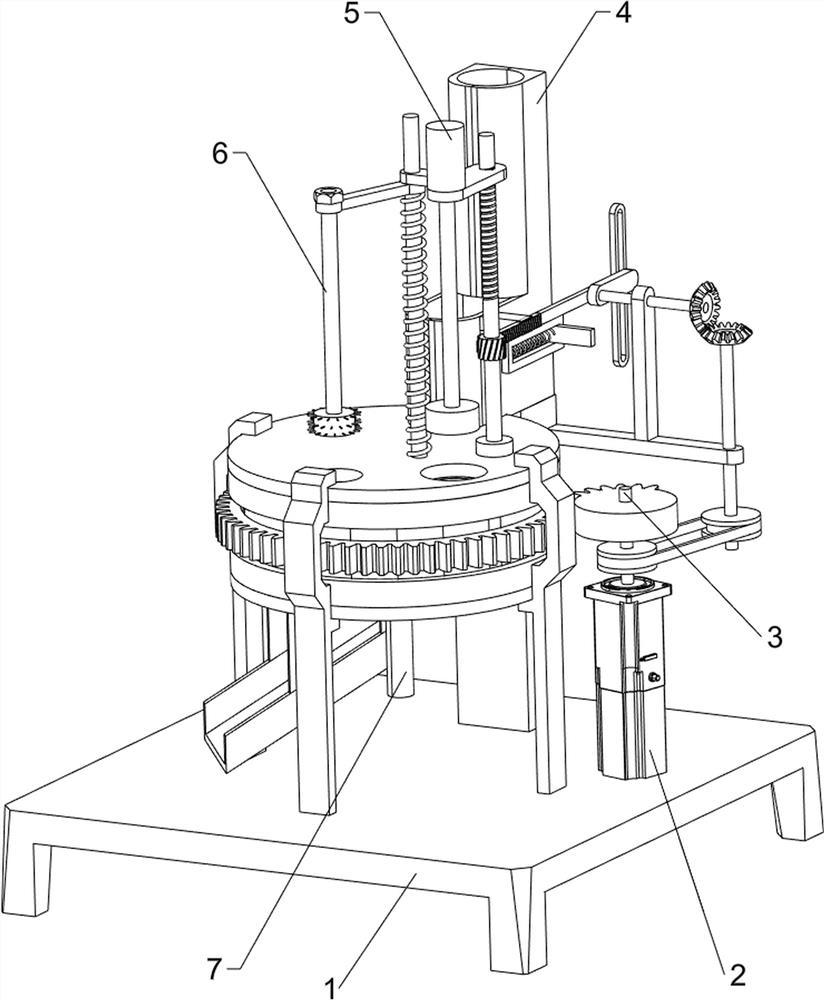

[0023] A hardware inner wall grinding equipment, such as Figure 1-3 As shown, it includes a base 1, a servo motor 2, a first rotating shaft 3, a feeding mechanism 4 and a grinding mechanism 5, a servo motor 2 is provided on the right front side of the top of the base 1, and a first rotating shaft 3 is provided on the output shaft of the servo motor 2. The top of the base 1 is provided with a feeding mechanism 4 , and the top of the base 1 is provided with a grinding mechanism 5 .

[0024] When people need to polish the inner wall of the hardware, first people place the hardware in the feeding mechanism 4, and then the servo motor 2 can be started, the output shaft of the servo motor 2 drives the first rotating shaft 3 to rotate, and the first rotating shaft 3 drives the feeding mechanism 4. The feeding mechanism 4 operates, the feeding mechanism 4 operates and then pushes the hardware into the grinding mechanism 5, and then the first rotating shaft 3 drives the grinding mecha...

Embodiment 2

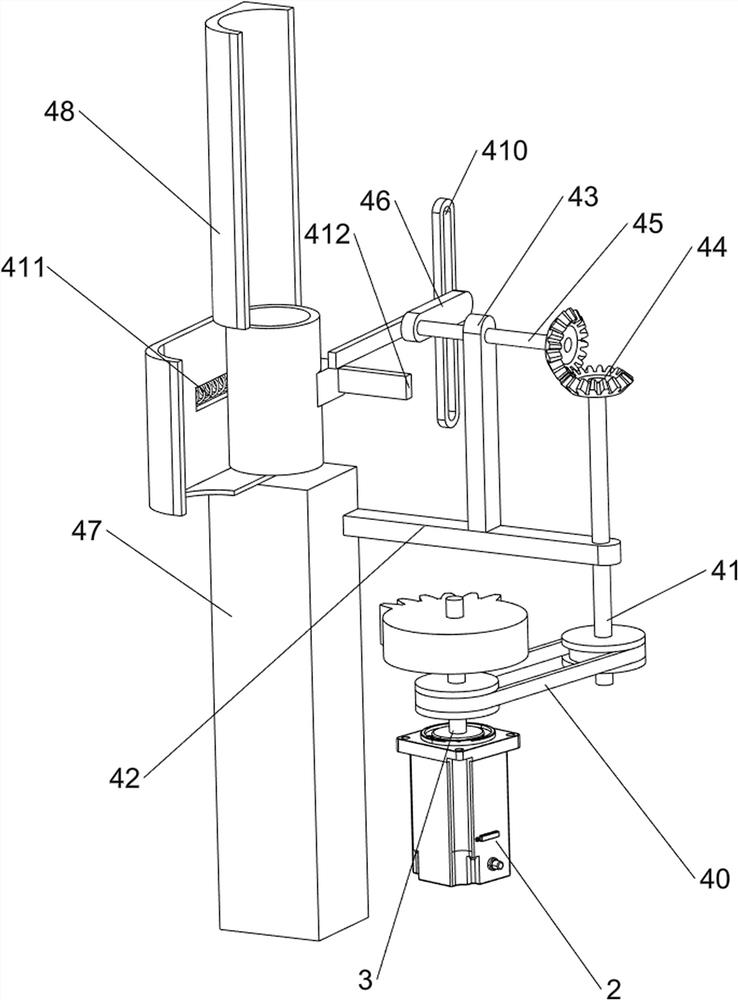

[0030] On the basis of Example 1, such as figure 1 , image 3 and Figure 4 Shown, also comprise cleaning mechanism 6, and cleaning mechanism 6 comprises slide block 60, second spring 61, connecting rod 62, brush 63 and unloading plate 65, slide bar 511 slide type is provided with slide block 60, slide block 60 The second spring 61 is connected with the upper support plate 51, the second spring 61 is sleeved on the slide bar 511, the left side of the slide block 60 is provided with a connecting rod 62, the bottom of the connecting bar 62 is provided with a brush 63, and the left side of the upper support plate 51 There is a feed hole 64 on the side, and a discharge plate 65 is provided at the bottom of the lower support plate 52, and the discharge plate 65 is located below the discharge hole.

[0031] When the nut block 59 moves downward, the nut block 59 drives the slide block 60 to slide downward, the second spring 61 is compressed, and the slide block 60 drives the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com