Peanut whole-process production line and method

A full-process and production line technology, applied in chemical instruments and methods, separating solids from solids with airflow, and types of packaging items, can solve the problems of less research on comprehensive utilization, insufficient technological innovation capabilities, and insufficient deep processing, etc. problem, to achieve the effect of solving high cost labor, uniform size, improving conveying speed and grading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

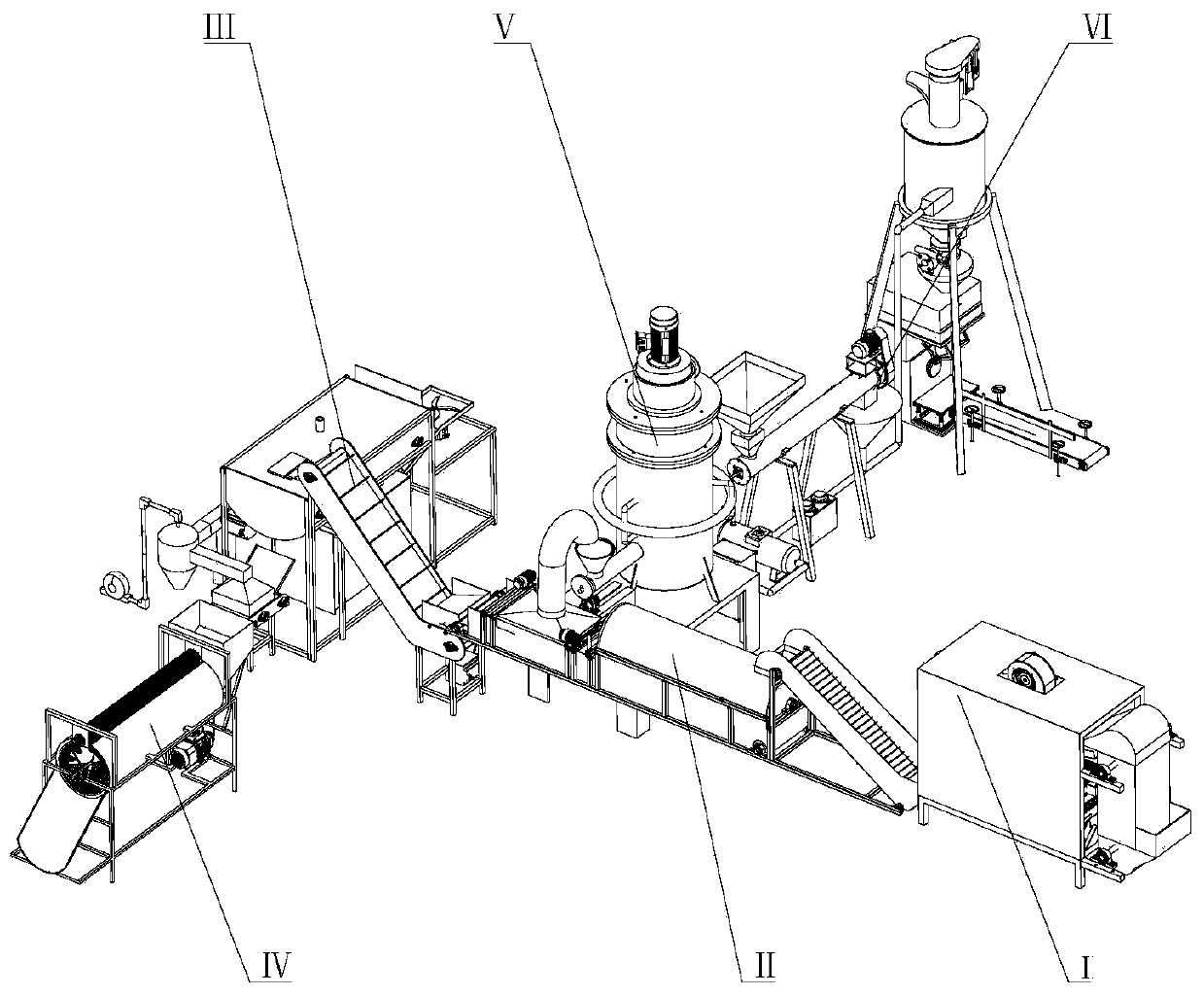

[0090] Attached below figure 1 - attached Figure 18 A kind of peanut full-process production line disclosed in this embodiment is further described;

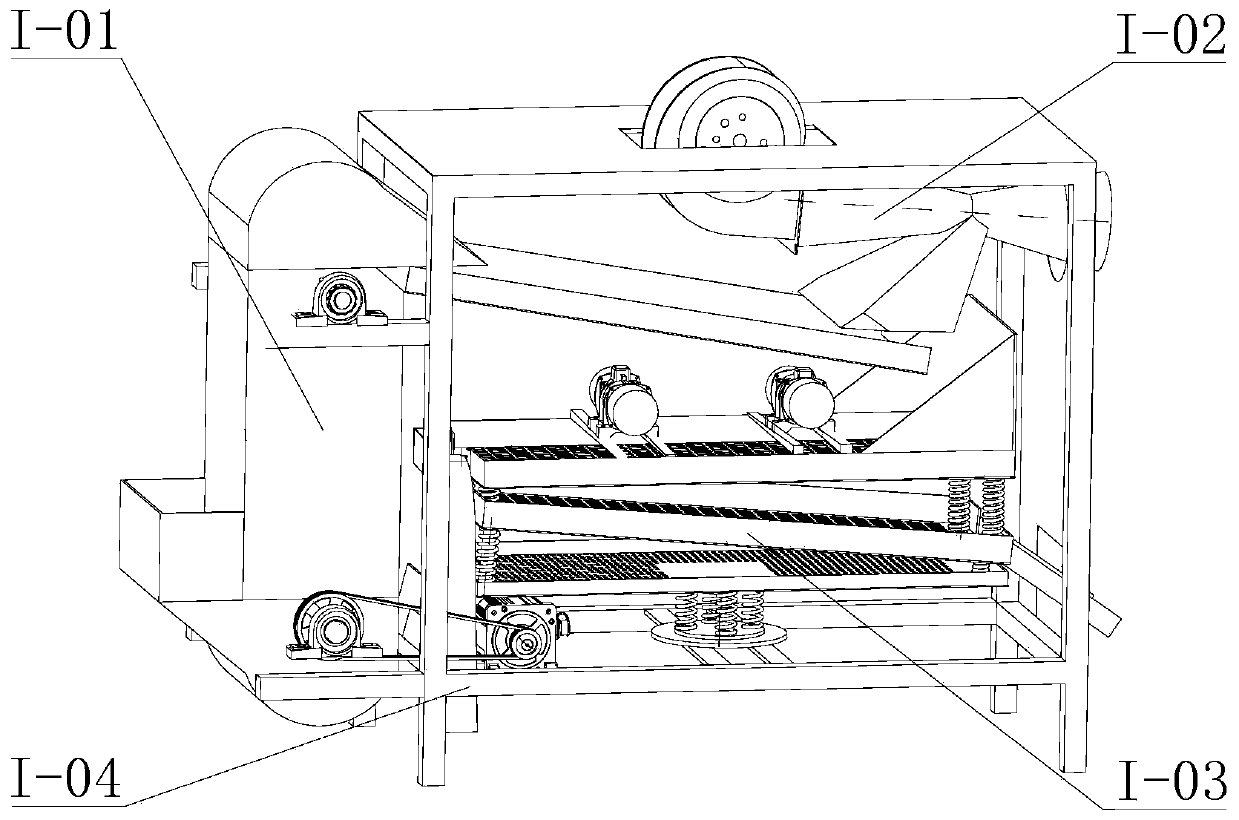

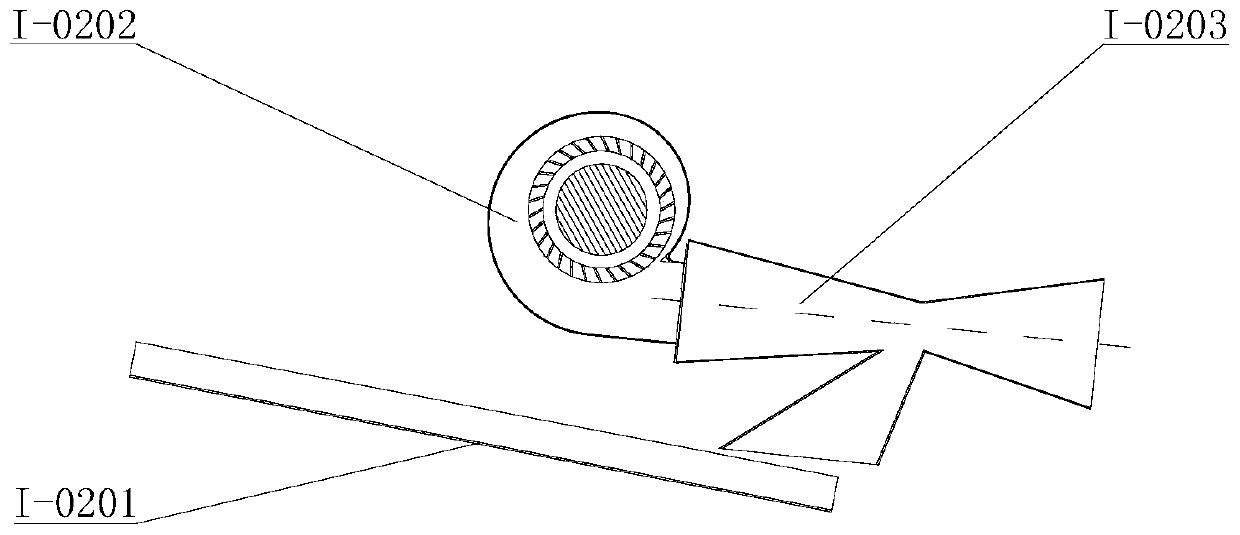

[0091] First, the adsorption multi-stage screening peanut cleaning system is introduced. Refer to attached figure 2 As shown, the adsorption multi-stage screening peanut cleaning system includes the first feeding device I-01, air selection mechanism I-02, vibration screening mechanism I-03 and the first frame I-04. The first feeding device I-01 is located on the side of the winnowing mechanism I-02 and the vibrating screening mechanism I-03, and the winnowing mechanism I-02 is located above the vibrating screening mechanism I-03.

[0092] The first feeding device I-01 is fixed on the first frame I-04 through the external bearing support of the drive drum inside it, and the winnowing mechanism I-02 is fixed to the positive pressure fan through fixing bolts to fix the first frame I-04 Above, the winnowing mechanism conducts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com