Sugarcane juicing equipment for agriculture and light industry

A light industry, juicing technology, applied in the fields of application, manufacturing tools, juice extraction, etc., can solve the problems of impurities falling into sugarcane juice, bagasse cannot be collected, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

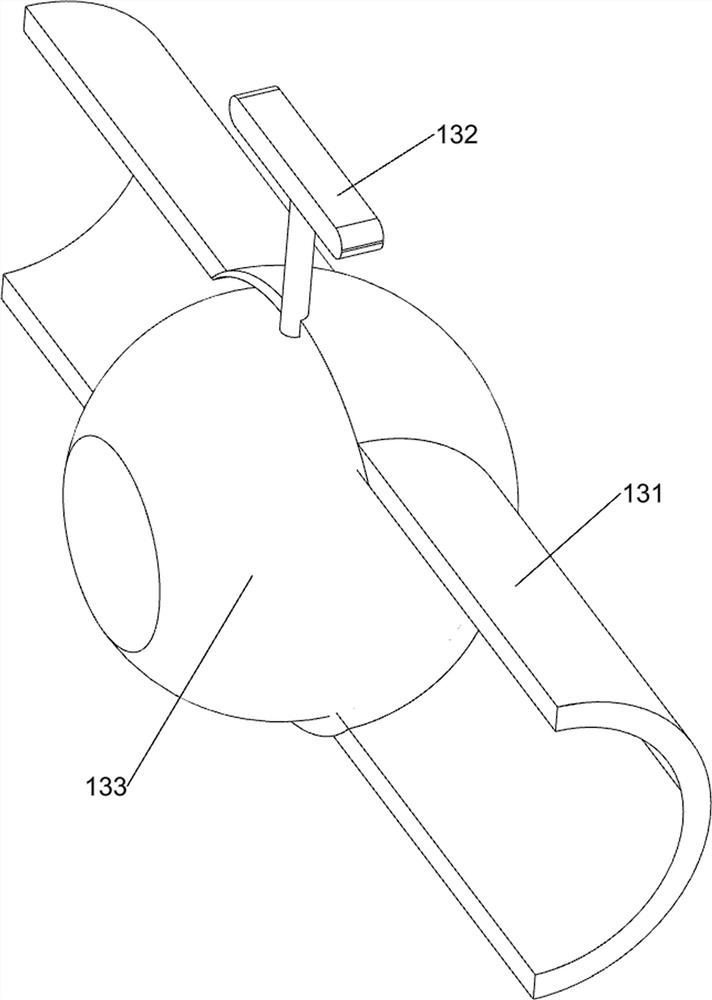

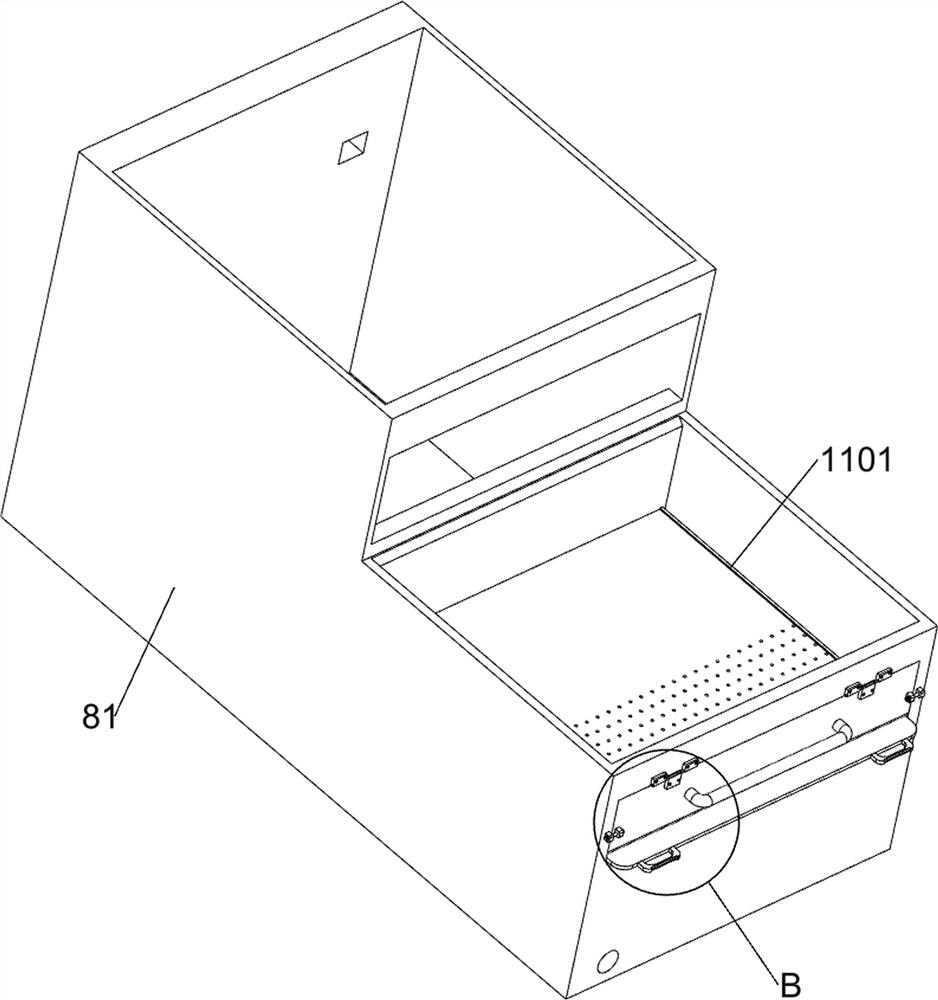

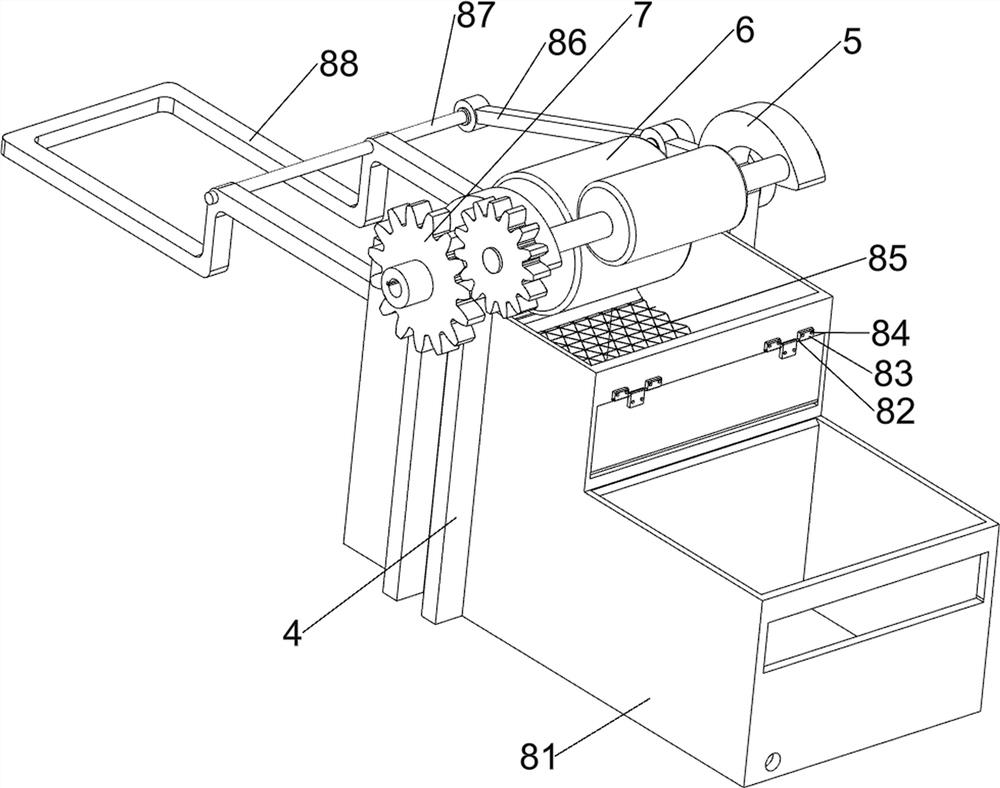

[0032] A kind of sugarcane juice extraction equipment for agricultural light industry, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, it includes a base plate 1, a support frame 2, a motor 3, a first support column 4, a small drum 5, a large drum 6, a full gear 7, a pushing mechanism 8 and a secondary juice extraction mechanism 9, and the front side of the top of the base plate 1 A support frame 2 is provided, a motor 3 is provided on the top of the support frame 2, a first support column 4 is arranged symmetrically front and back on the top of the base plate 1, and a small roller 5 is provided in a rotating manner between the upper right side of the first support column 4, and the first support column 4. There is a large drum 6 rotating between the left side of the upper part. The large drum 6 is connected to the output shaft of the motor 3. The front end of the large drum 6 and the small drum 5 is equipped with a full gear 7. The two full gears...

Embodiment 2

[0038] On the basis of Example 1, such as figure 1 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, it also includes a blanking mechanism 10. The blanking mechanism 10 includes a protective shell 1001, a second support column 1002, a discharge port 1003, a storage frame 1004, a movable baffle 1005, a third support column 1006, and a third slide. Rail 1007, the fourth spring 1008, the second movable rod 1009 and the fourth support column 1010, the top left side of the collection frame 81 is provided with a protective shell 1001, and the small drum 5 and the large drum 6 pass through the protective shell 1001 in a rotating manner. The top of the protective shell 1001 is symmetrically provided with a second support column 1002 front and back, and a discharge port 1003 is provided between the left side of the second support column 1002. A third support column 1006 is provided, and a storage frame 1004 is provided on the top of the third s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com