Water-based environmentally friendly wood putty and preparation method

An environmental protection and wood technology, applied in the direction of filling slurry, etc., can solve the problems affecting the physical and mental health of workers and applicable people, poor adhesion, poor sealing, etc., and achieve the effect of good hardness, strong adhesion and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

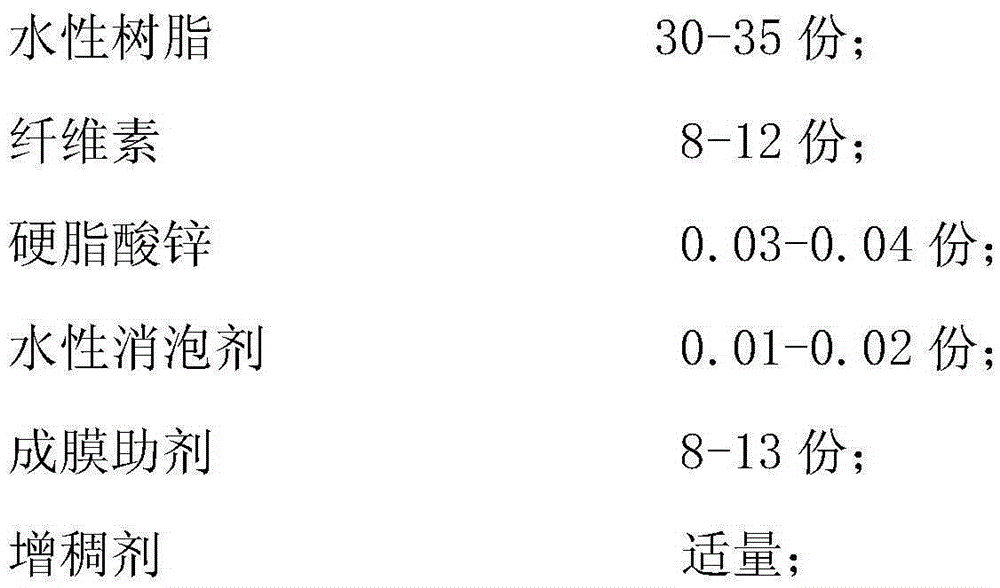

[0025] Embodiment 1: a kind of water-based environmental protection wood putty, comprises the raw material of following weight part:

[0026]

[0027]

[0028] The prepared water-based wood putty is an environmentally friendly coating that is scraped on the surface of wood, and it is more environmentally friendly and safer to replace traditional ash products.

[0029] The water-based environment-friendly resin has no harmful volatile matter, is non-toxic and harmless, and belongs to a green environment-friendly resin.

[0030] The film-forming aids are low-toxic and environment-friendly reagents,

[0031] In the water-based environmentally friendly wood putty, the defoamer used is a water-based environmentally friendly and non-toxic defoamer without volatile harmful substances.

[0032] The filler used is 1250 mesh fineness, and the putty is smooth and fine after use, easy to apply and scrape, and the surface is very smooth after surface drying.

[0033] Described zinc...

Embodiment 2

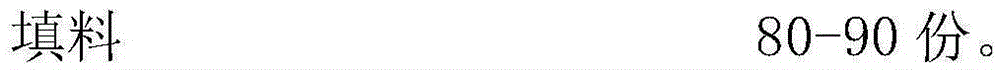

[0038] A water-based environment-friendly wood putty comprises the following raw materials in parts by weight.

[0039]

[0040] The prepared water-based wood putty is an environmentally friendly coating that is scraped on the surface of wood, and it is more environmentally friendly and safer to replace traditional ash products.

[0041] The water-based environmental protection resin has no harmful volatiles, is non-toxic and harmless, and is a green environmental protection resin.

[0042] The film-forming aid is a low-toxic and environment-friendly reagent;

[0043] The defoamer is a water-based, environmentally friendly, non-toxic defoamer without volatile and harmful substances.

[0044] The filler is 1250 mesh fineness. After use, the putty is smooth and fine, easy to apply and scrape. After the surface is dry, the surface is very smooth.

[0045] Described zinc stearate is for increasing the ease of polishing after the putty is dried, and makes the putty easier to p...

Embodiment 3

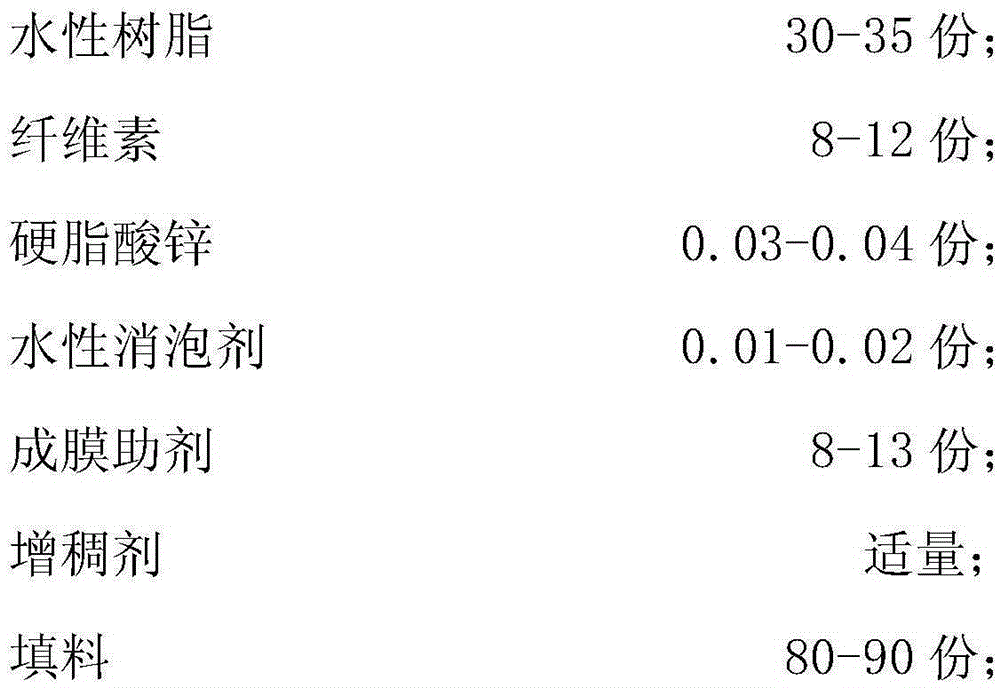

[0051] A kind of water-based environment-friendly wood putty has the following raw materials in parts by weight;

[0052]

[0053] The prepared water-based wood putty is an environmentally friendly coating that is scraped on the surface of wood, and it is more environmentally friendly and safer to replace traditional ash products.

[0054] The water-based environmental protection resin has no harmful volatiles, is non-toxic and harmless, and is a green environmental protection resin.

[0055] Coalescing aids are low-toxic and environmentally friendly reagents;

[0056] The defoamer used is a water-based, environmentally friendly and non-toxic defoamer without volatile harmful substances.

[0057] The filler is 1250 mesh fineness. After use, the putty is smooth, fine and easy to apply and scrape. After the surface is dry, the surface is very smooth.

[0058] Described zinc stearate is for increasing the ease of polishing after the putty is dried, and makes the putty easier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com