Novel grout supplementing method and device for micro pile

A micropile and grout filling technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as grouting misunderstandings, affecting grouting quality, and slow grouting process, so as to prevent grout from flowing back and ensure grouting Effect, the effect of evenly filling the slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

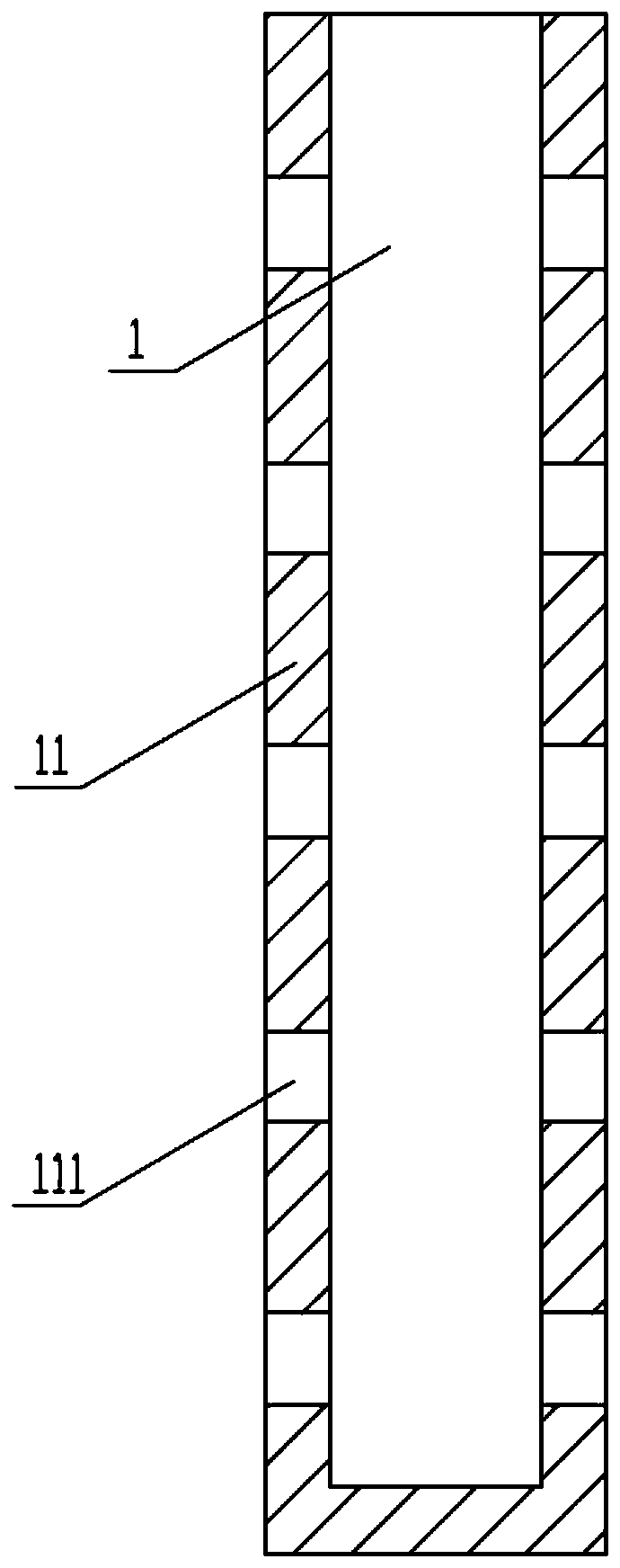

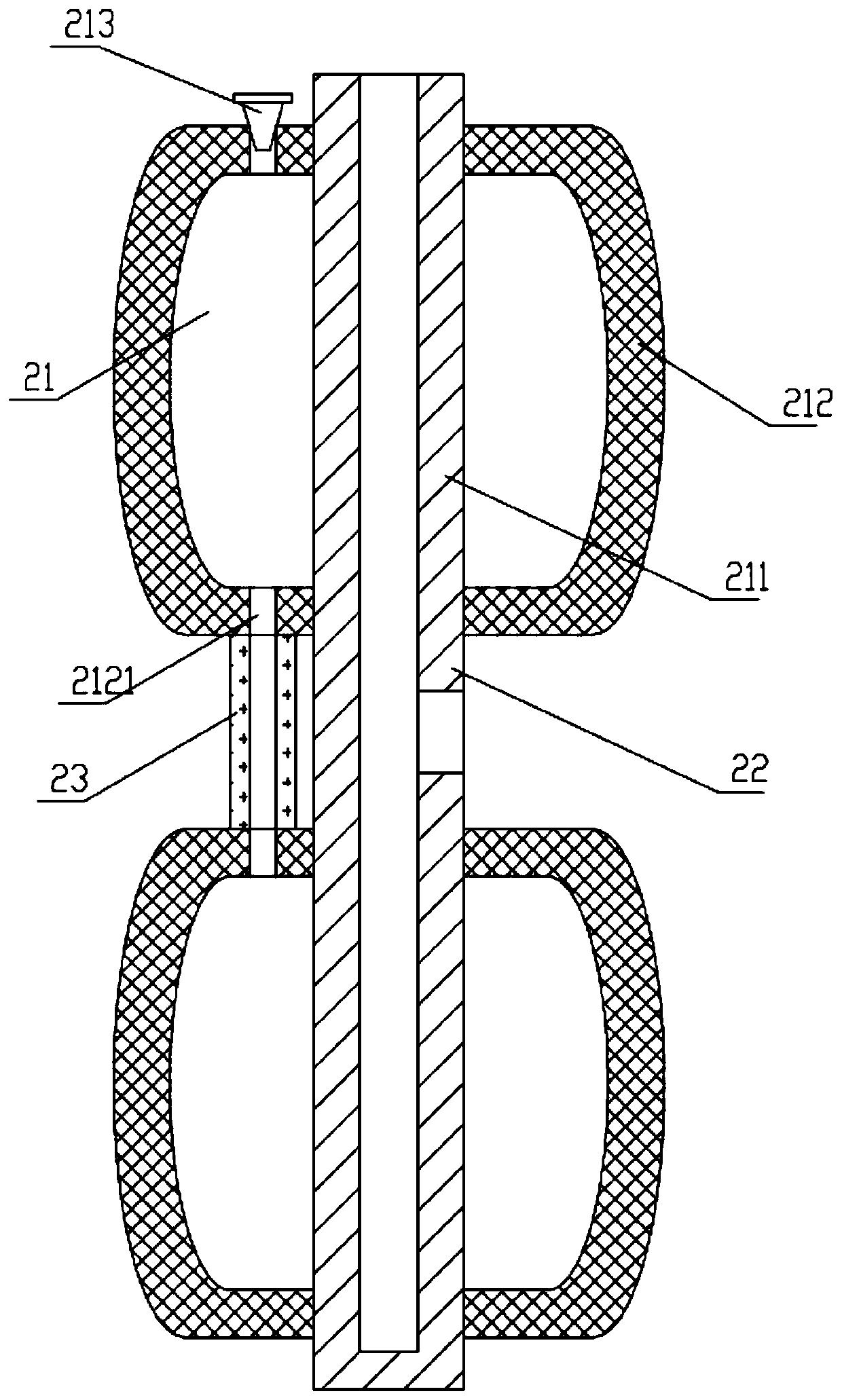

[0045] Such as Figure 1-4 As shown, the present invention discloses a novel grouting device for micropile, grouting pipe 1, positioning grouting device 2;

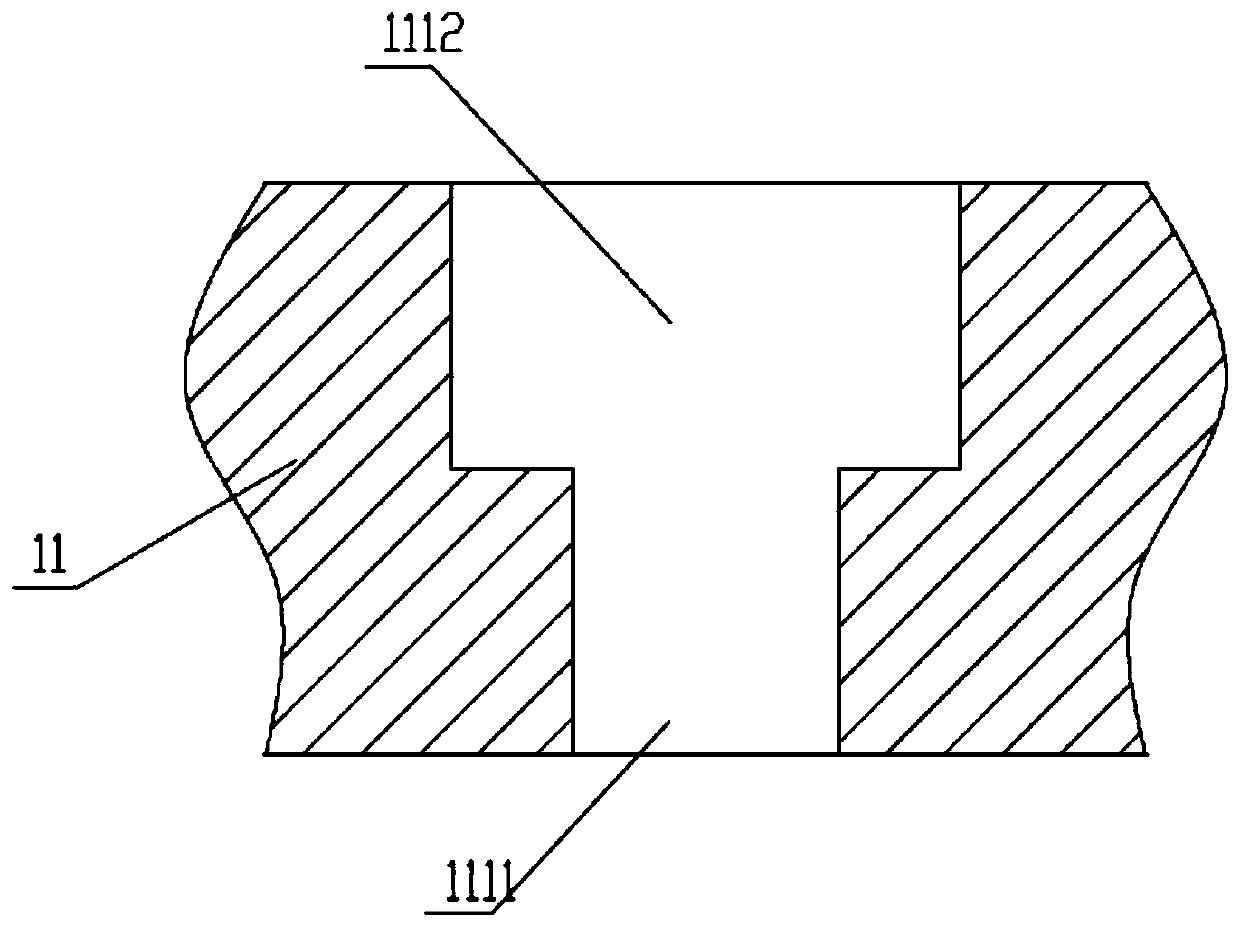

[0046] The grout filling pipe 1 includes a pipe body 11 and a non-return device 12; the pipe body 11 is a hollow pipe with one end open and one end closed, and a grout filling hole 111 is arranged on the side wall of the pipe body 11; the non-return device 12 is set at the grouting hole 111 to ensure that the fluid can only flow outward in one direction from the inside of the pipe body 11;

[0047] The positioning grouting device 2 includes a plugging part 21 and a grouting part 22; the grouting part 22 is connected with the plugging part 21 up and down; the plugging part 21 is a hollow jacket structure, including an inner tube 211. Outer jacket 212, a deformable space is formed between the outer jacket 212 and the inner pipe 211, and the outer jacket 212 is provided with a vent 2121; the grout filling part 22 is a commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com