Harvester brake fluid vacuum filling system and method

A technology for filling systems and brake fluids, applied in liquid distribution, conveying or transfer devices, special distribution devices, packaging, etc. Avoid malfunction of the main spool, easy to operate, and optimize the effect of the output pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

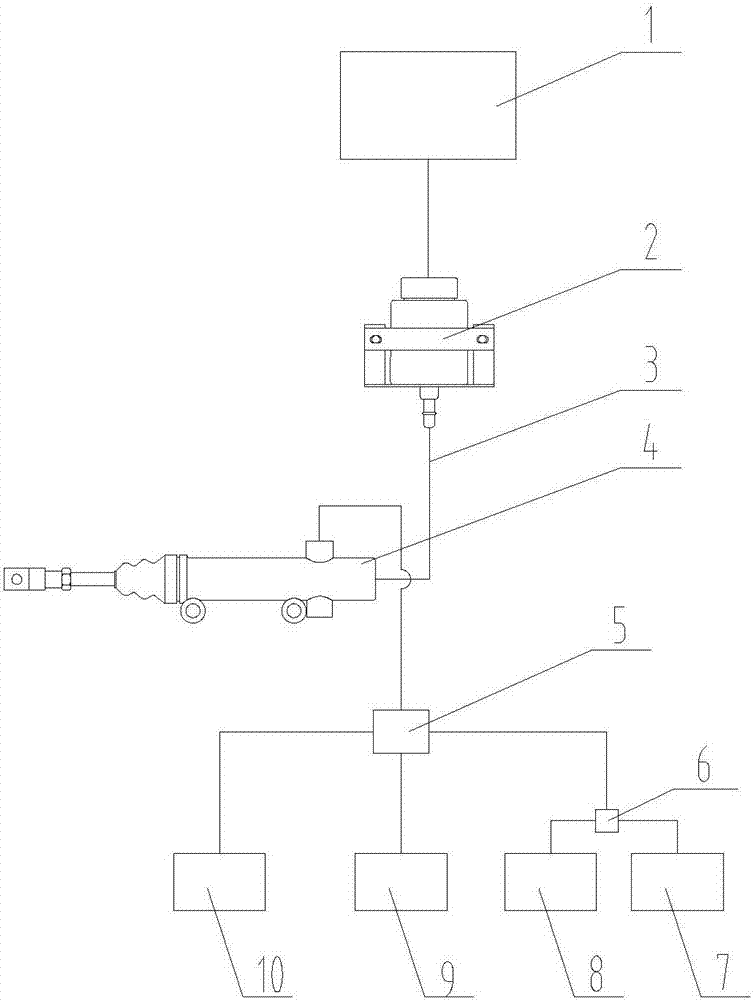

[0030] Such as figure 1 As shown, the harvester brake fluid vacuum filling system includes a brake oil pot 2 and a brake master cylinder 4, the oil outlet of the brake oil pot 2 is connected to the oil inlet of the brake master cylinder 4 through the brake pipeline 3, The oil outlet of the brake master cylinder 4 is respectively connected to the right rear wheel brake cylinder 7, the left rear wheel brake cylinder 8, the right front wheel brake cylinder 9, the left front wheel brake cylinder through the four-way joint body 5. Pump 10, the pipeline between the right rear wheel brake cylinder 7 and the left rear wheel brake cylinder 8 connects the tee joint body 6, which is the prior art. The harvester brake fluid vacuum filling system also includes a vacuum filling machine 1, and the filling gun head of the vacuum filling machine 1 is clamped and sealed with the filling port of the brake oil pot 2.

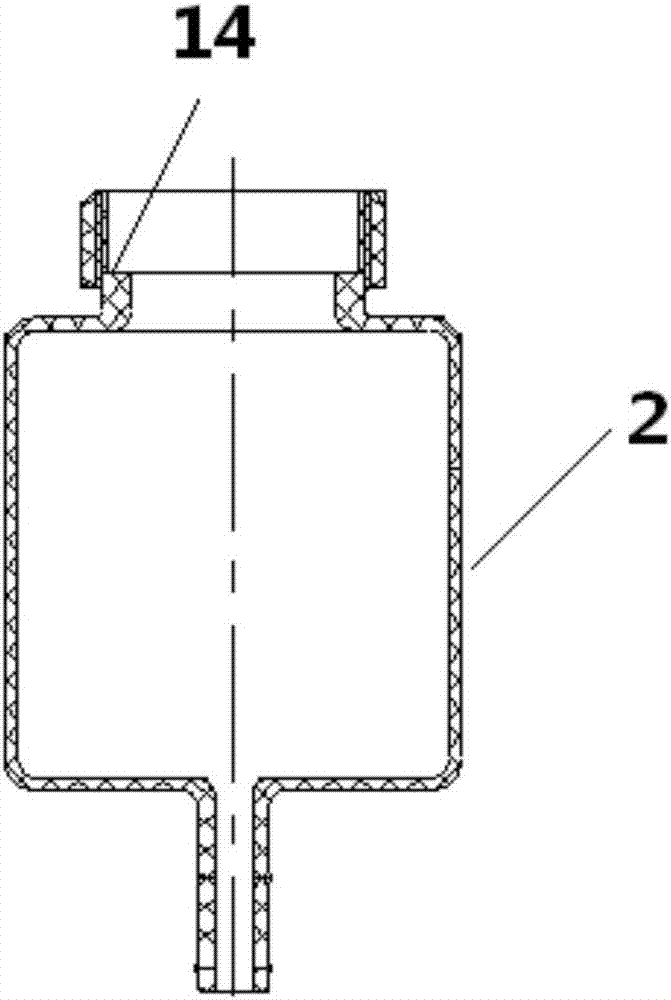

[0031] Such as figure 2 As shown, the filling port of the brake oil pot 2 i...

Embodiment 2

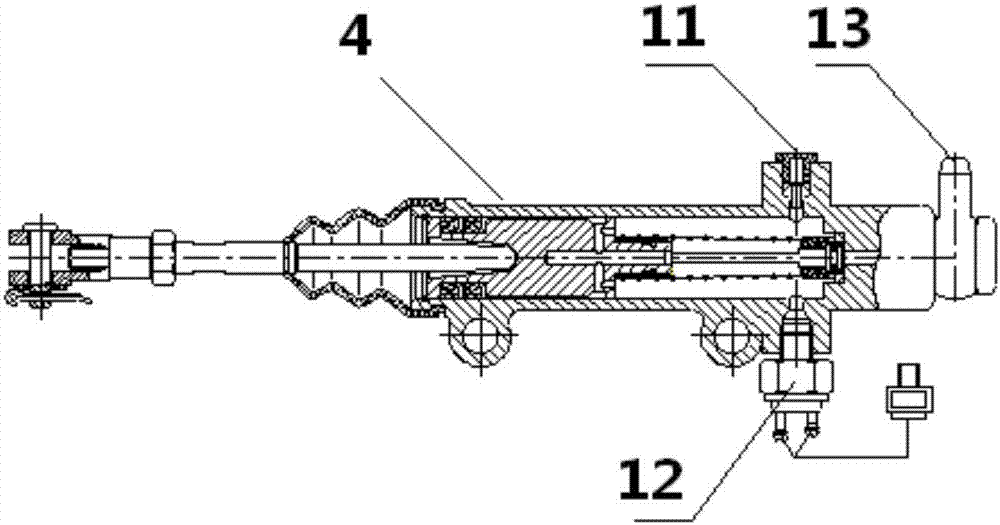

[0033] Such as image 3 As shown, the oil outlet 11 of the brake master cylinder 4 is located above the brake master cylinder, and the brake switch 12 is located below the brake master cylinder, corresponding to the position of the oil outlet 11 of the brake master cylinder. The oil inlet 13 of the pump is positioned at the top of the brake master cylinder tail. Other structures of the brake fluid vacuum filling system are the same as those in Embodiment 1.

[0034] When filling, include the following steps:

[0035] Step 1: Unscrew the cover of the brake oil pot, remove the inner cover and the filter screen of the oil pot, and place it in a nearby reliable place; clamp the filling gun head of the vacuum filler 1 to the fuel port of the brake oil pot 2, Vacuumize the gas in the brake oil pot 2, brake pipeline 3, brake master cylinder 4 and brake master cylinder output pipeline by filling the nozzle;

[0036] Step 2: Pressurize and inject brake fluid into the brake oil pot t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com