Disc grinder

A grinding machine and disc technology, applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of insufficient smoothness of the sprayed surface, high manual labor intensity, and harsh working environment, so as to reduce the cost of manual work and operating intensity, improving operating efficiency, and flexible and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

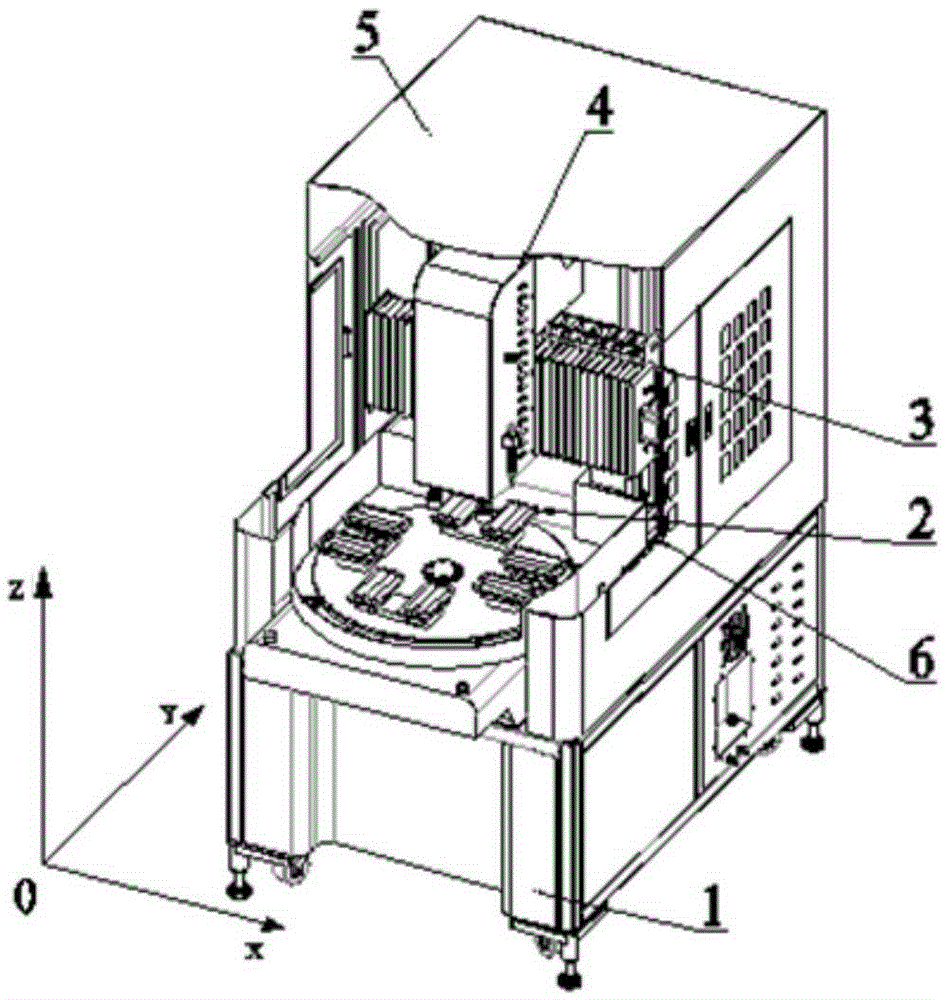

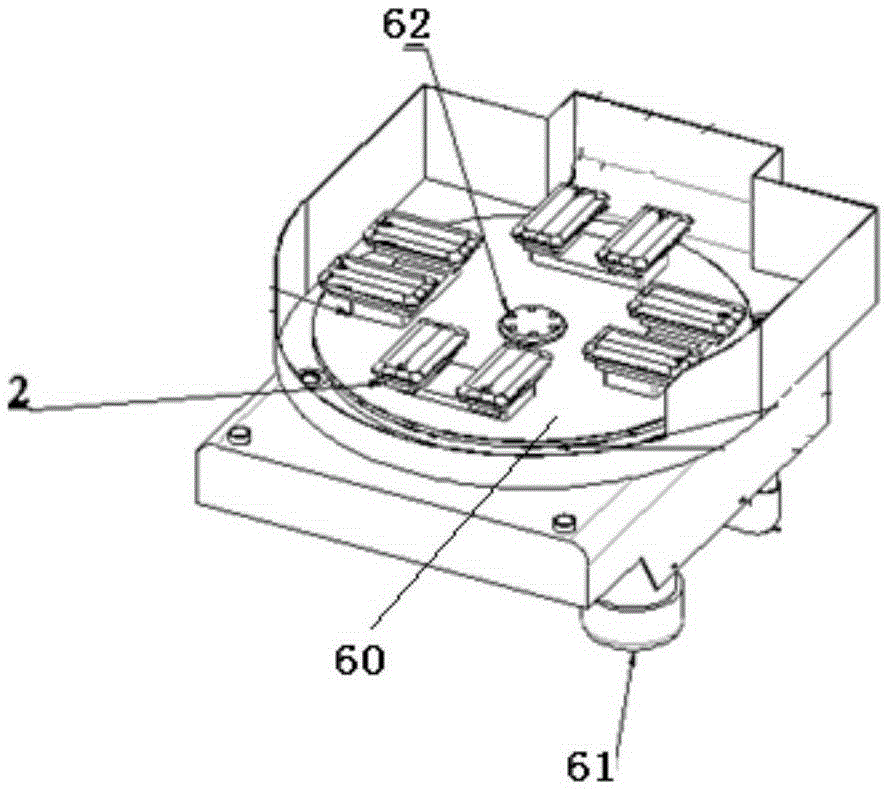

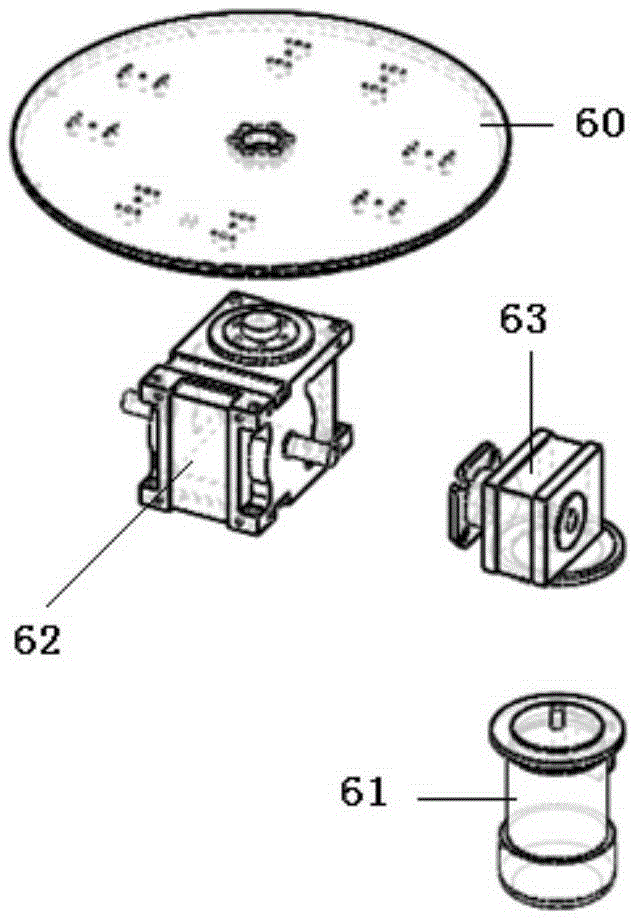

[0028] refer to Figure 1 to Figure 9 , in one embodiment, a disc grinder, comprising a frame 1, a machine cover 5, a jig assembly 2, a disc assembly 6, a grinding assembly 4 and a three-axis carrying assembly 3, the jig assembly 2 Installed on the disc assembly 6, the grinding assembly 4 is installed on the three-axis carrying assembly 3, the three-axis carrying assembly 3 is used to carry the grinding assembly 4 along the vertical Z-axis and the horizontal The X-axis and Y-axis perpendicular to each other in the direction move to realize the position adjustment of the grinding assembly 4, and the disc assembly 6 is used to drive the jig assembly 2 to rotate and shift, so that the jig assembly The product fixed on the jig assembly 2 is moved to the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com