Circular pipe polishing device for heating and ventilation

A technology of polishing device and round tube, which is applied to grinding driving device, surface polishing machine tool, grinding/polishing equipment, etc. Work load and effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

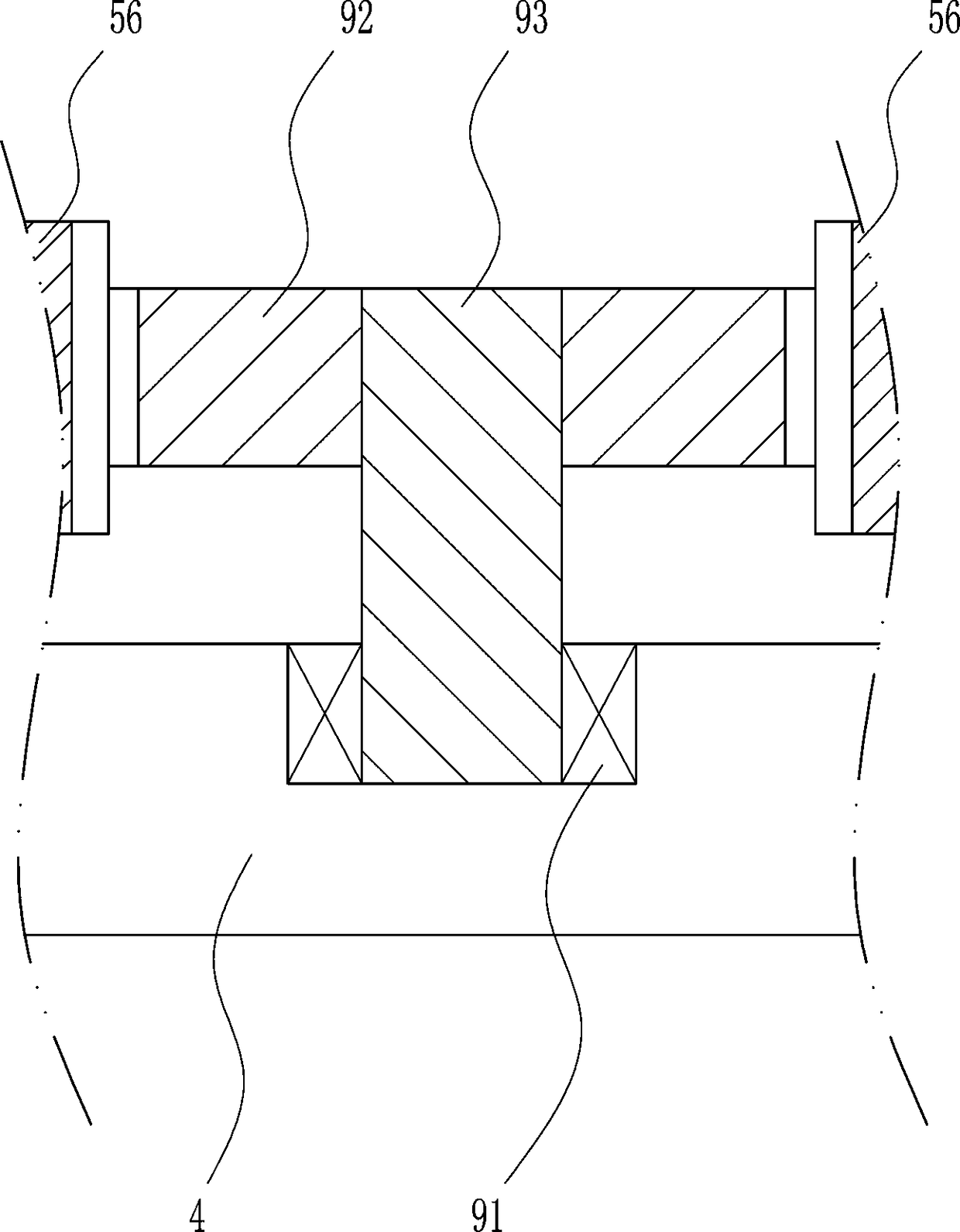

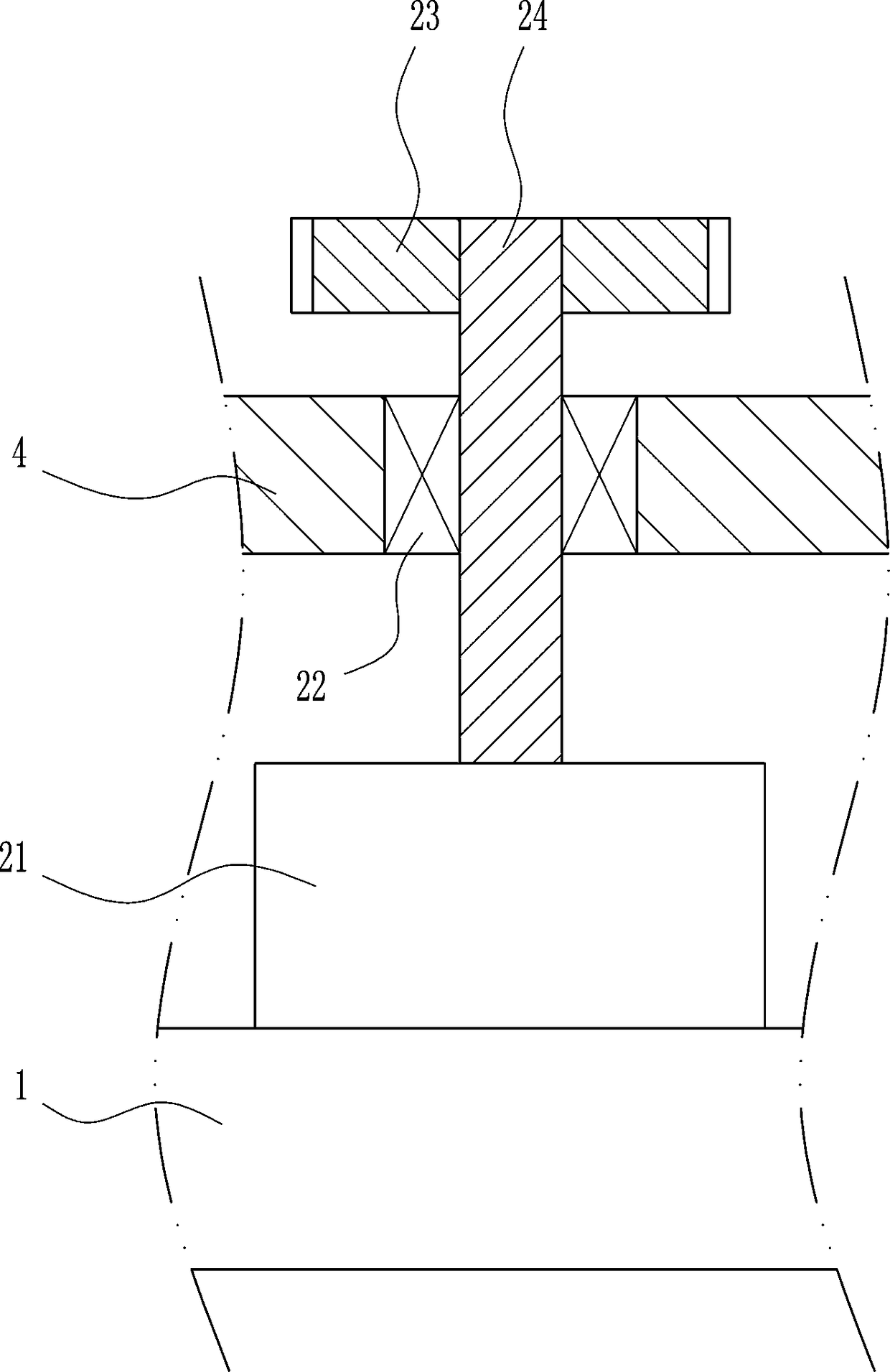

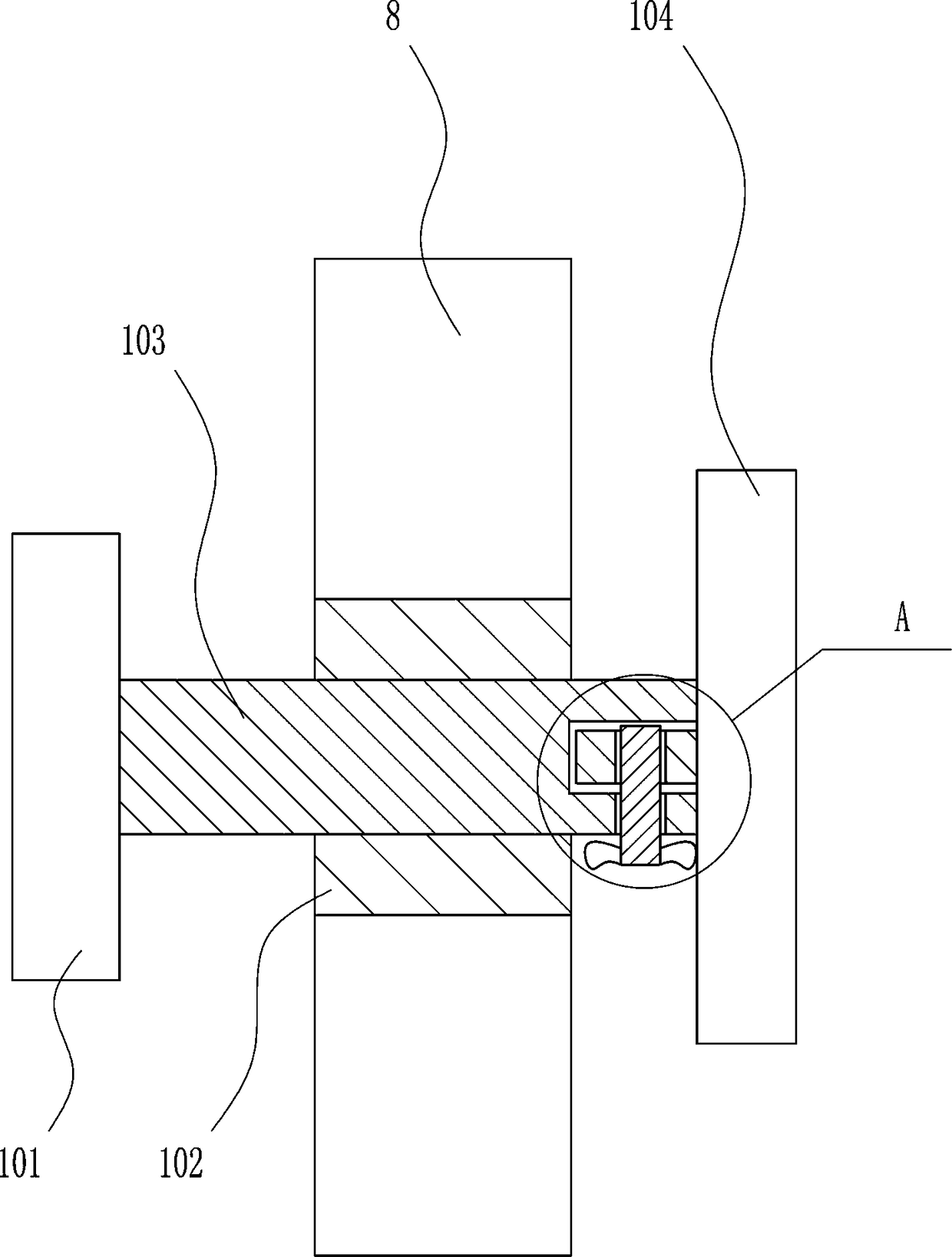

[0027] A warm general round tube polishing device, such as Figure 1-8 As shown, it includes a bottom plate 1, a driving mechanism 2, a support seat 3, a first mounting plate 4, a rotating mechanism 5, a slide rail 6, a slider 7, a lifting plate 8, a transmission mechanism 9, a grinding mechanism 10, a lifting mechanism 11 and The second mounting plate 12; the second mounting plate 12 is affixed to the top of the base plate 1 through the support seat 3, and the driving mechanism 2 is affixed to the side of the base plate 1; a plurality of rotating mechanisms 5 are fixed to the first mounting plate 4 at equal intervals, And the rotating mechanism 5 close to the driving mechanism 2 is connected in transmission with the driving mechanism 2; the two rotating mechanisms 5 are connected by a transmission mechanism 9, and the slide rail 6 is fixed on one side of the mounting plate in the vertical direction, and the second mounting plate 12 Fixed on the top of the slide rail 6, the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com