Automatic grinding machine for surface of polygonal metal plate

A technology of metal plates and polygons, applied in the direction of grinding racks, metal processing equipment, grinding machine tool parts, etc., can solve the problems of time-consuming, labor-intensive, and tired staff, so as to save time, reduce manual operations, avoid damaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

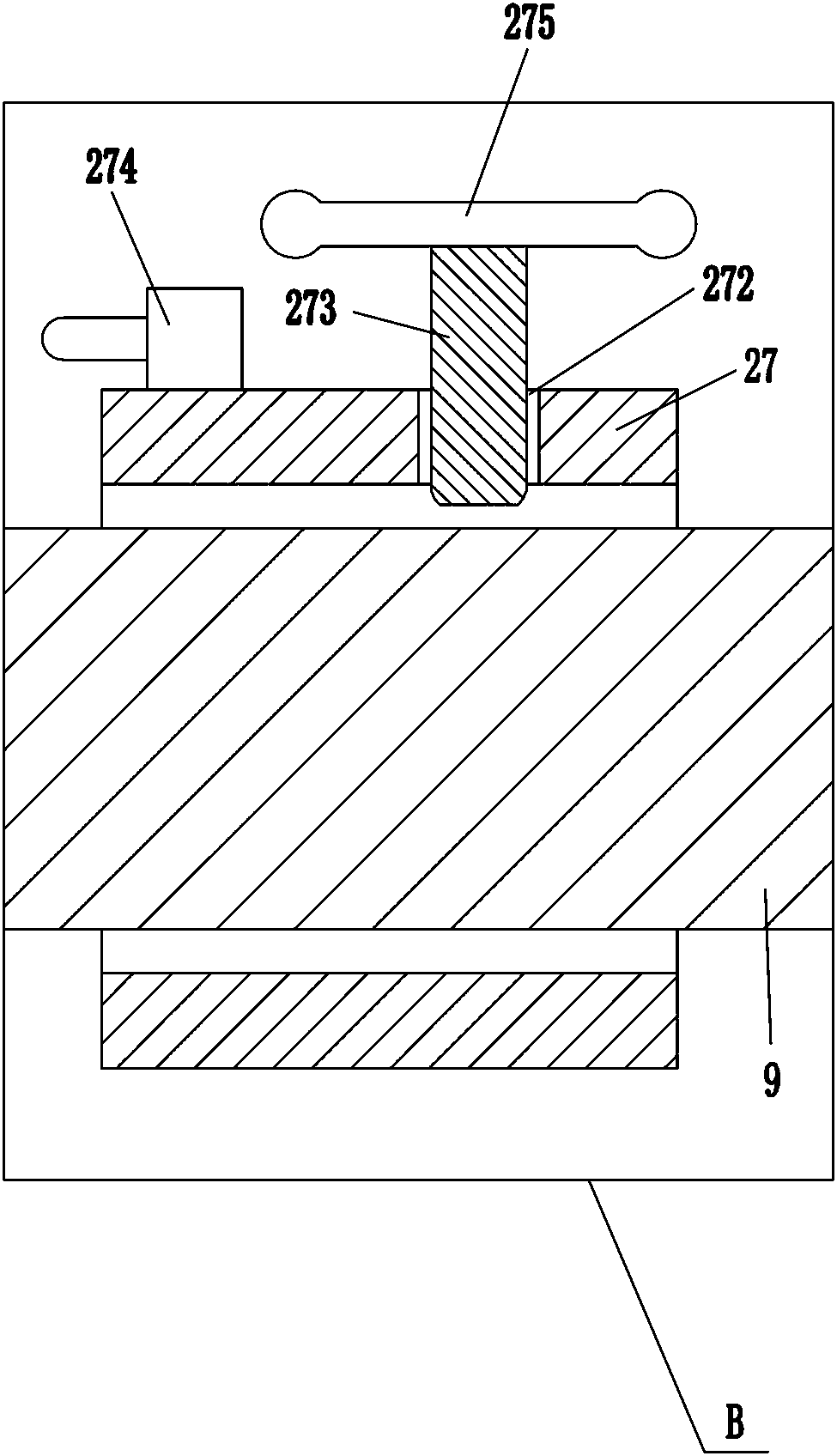

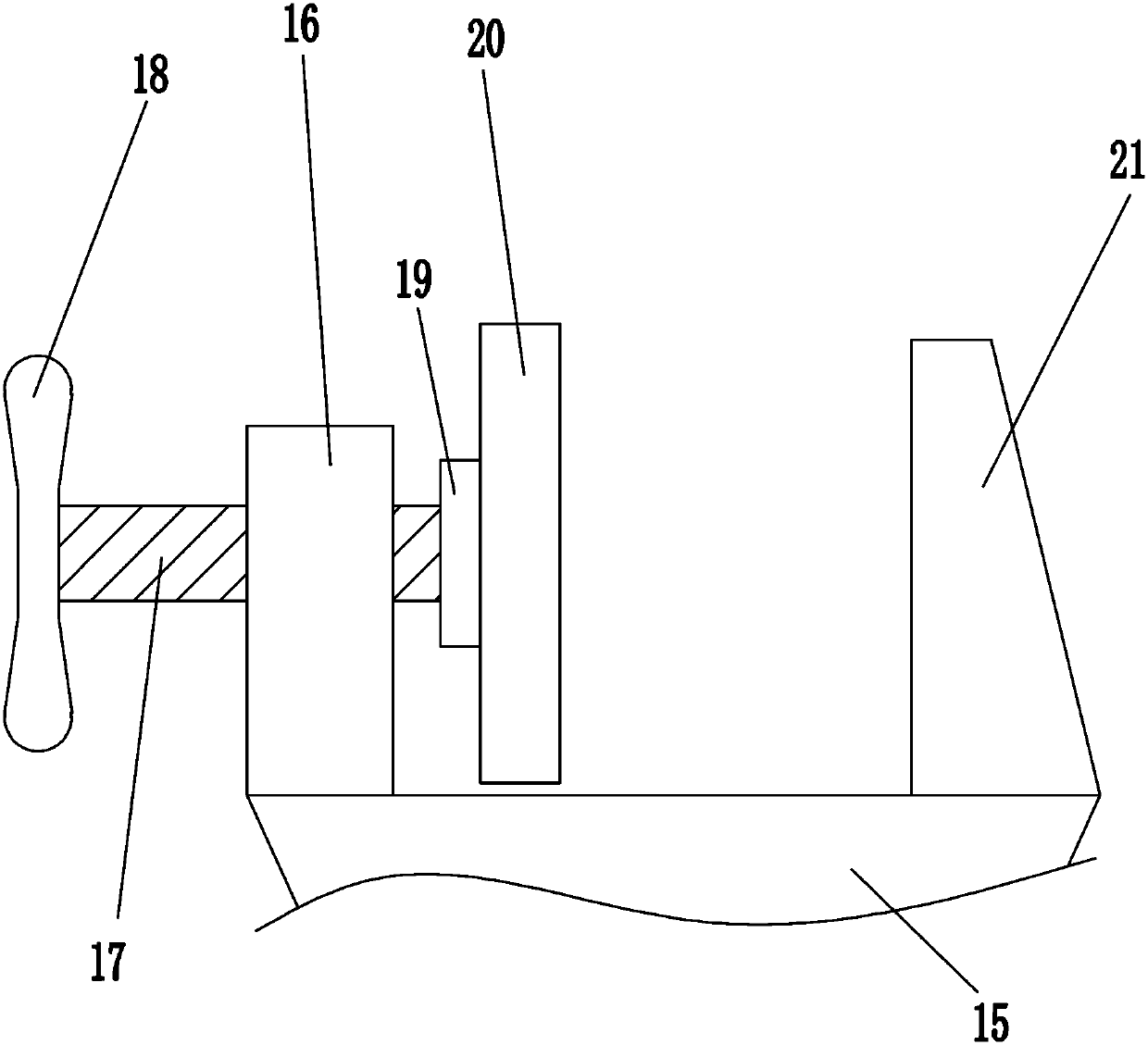

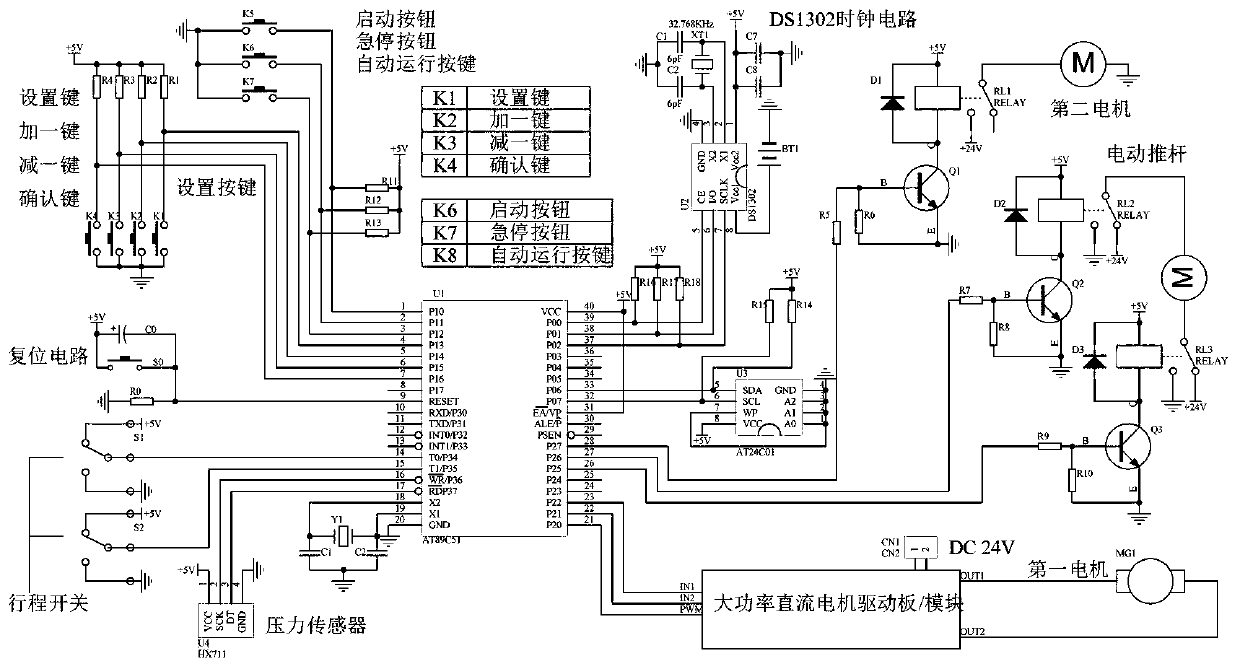

[0021] An automatic grinding machine for the surface of a polygonal metal plate, such as Figure 1-7 As shown, it includes a support seat 1, a first motor 2, a screw rod 3, a first nut 4, a mounting plate 5, a second motor 6, a grinding wheel 7, a bearing seat 8, a guide rod 9, a guide sleeve 10, a cantilever 11, Electric push rod 12, curved plate 13, rolling ball 14, mounting block 15, second nut 16, second screw rod 17, handle 18, first bushing 19, pressure plate 20, baffle plate 21, fixing mechanism 22, control Box 30, start button 31, emergency stop button 32, left shift button 33, right shift button 34, down button 35 and up button 36, the first motor 2 is installed on the upper left side of the front side of the support base 1, and the support base 1 is connected by bolts It is connected with the first motor 2 in the same way, bearing housings 8 are installed on the left and right sides of the upper front side of the support base 1, and a screw rod 3 is installed between...

Embodiment 2

[0023] An automatic grinding machine for the surface of a polygonal metal plate, such as Figure 1-7As shown, it includes a support seat 1, a first motor 2, a screw rod 3, a first nut 4, a mounting plate 5, a second motor 6, a grinding wheel 7, a bearing seat 8, a guide rod 9, a guide sleeve 10, a cantilever 11, Electric push rod 12, curved plate 13, rolling ball 14, mounting block 15, second nut 16, second screw rod 17, handle 18, first bushing 19, pressure plate 20, baffle plate 21, fixing mechanism 22, control Box 30, start button 31, emergency stop button 32, left shift button 33, right shift button 34, down button 35 and up button 36, the first motor 2 is installed on the upper left side of the front side of the support base 1, the upper part of the front side of the support base 1 Bearing housings 8 are installed on the left and right sides of the bearing housing 8, and a screw mandrel 3 is installed between the two bearing housings 8. The left end of the screw mandrel 3...

Embodiment 3

[0026] An automatic grinding machine for the surface of a polygonal metal plate, such as Figure 1-7 As shown, it includes a support seat 1, a first motor 2, a screw rod 3, a first nut 4, a mounting plate 5, a second motor 6, a grinding wheel 7, a bearing seat 8, a guide rod 9, a guide sleeve 10, a cantilever 11, Electric push rod 12, curved plate 13, rolling ball 14, mounting block 15, second nut 16, second screw rod 17, handle 18, first bushing 19, pressure plate 20, baffle plate 21, fixing mechanism 22, control Box 30, start button 31, emergency stop button 32, left shift button 33, right shift button 34, down button 35 and up button 36, the first motor 2 is installed on the upper left side of the front side of the support base 1, the upper part of the front side of the support base 1 Bearing housings 8 are installed on the left and right sides of the bearing housing 8, and a screw mandrel 3 is installed between the two bearing housings 8. The left end of the screw mandrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com