Rapid grinding device for hardware parts

A fast technology for hardware parts, applied in the direction of grinding drive device, grinding machine, grinding frame, etc., can solve the problems of troublesome workers' personal safety, poor grinding effect, low efficiency, etc., so as to facilitate grinding operation and reduce grinding time , fast grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

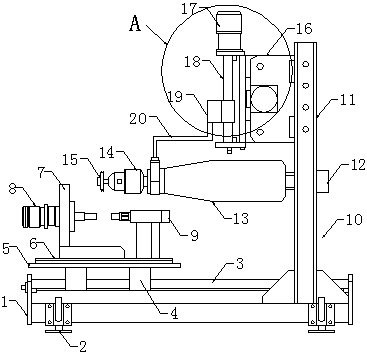

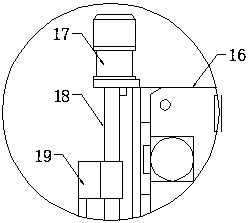

[0021] Such as Figure 1-2 As shown, this specific embodiment adopts the following technical solutions: a fast grinding device for hardware parts, including a support base 1, a bearing 2, a first transverse slide rail 3, a slider 4, a workbench 5, and a second transverse slide rail 6 , clamping frame 7, rotating motor 8, positioning frame 9, column 10, longitudinal slide rail 11, lifting slide seat 12, driving motor 13, spindle box 14, grinding joint 15, fixing piece 16, screw stepper motor 17, Screw rod 18, sleeve 19 and connector 20, the first transverse slide rail 3 is fixedly installed at both ends of the support base 1, and the support base 1 is slidably installed with the slider 4 through the first transverse slide rail 3, on the slider 4 A workbench 5 is fixedly connected, and a second transverse slide rail 6 is provided on the workbench 5, and a clamping frame 7 is slidably installed on the workbench 5 through the second transverse slide rail 6, and the corresponding w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com