Desktop type grinding and polishing belt sander working table

A technology for polishing abrasive belts and workbenches, applied in the field of robots, can solve the problems of high purchase cost and follow-up maintenance cost, low processing cost of small parts, high labor intensity, etc. The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

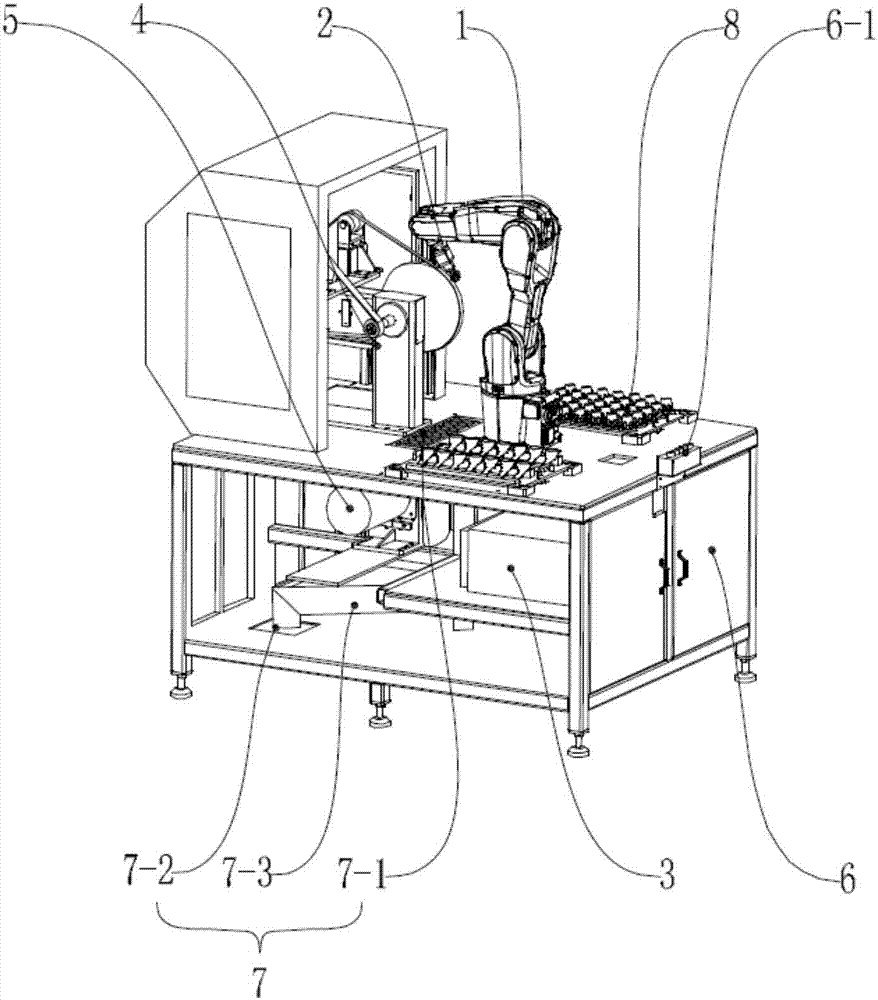

[0027] A desktop grinding and polishing belt machine workbench, including a mechanical arm 1, a fixture 2, a robot controller 3, a single-drive grinding and polishing mechanism 4, a grinding motor 5, a PLC control system and a workbench 6;

[0028] The mechanical arm 1 and the single-drive grinding and polishing mechanism 4 are installed on the upper surface of the workbench 6;

[0029] The clamp 2 is replaceably mounted on the free end of the mechanical arm 1;

[0030] The robot controller 3 is arranged in the workbench 6 to control the activities of the mechanical arm 1;

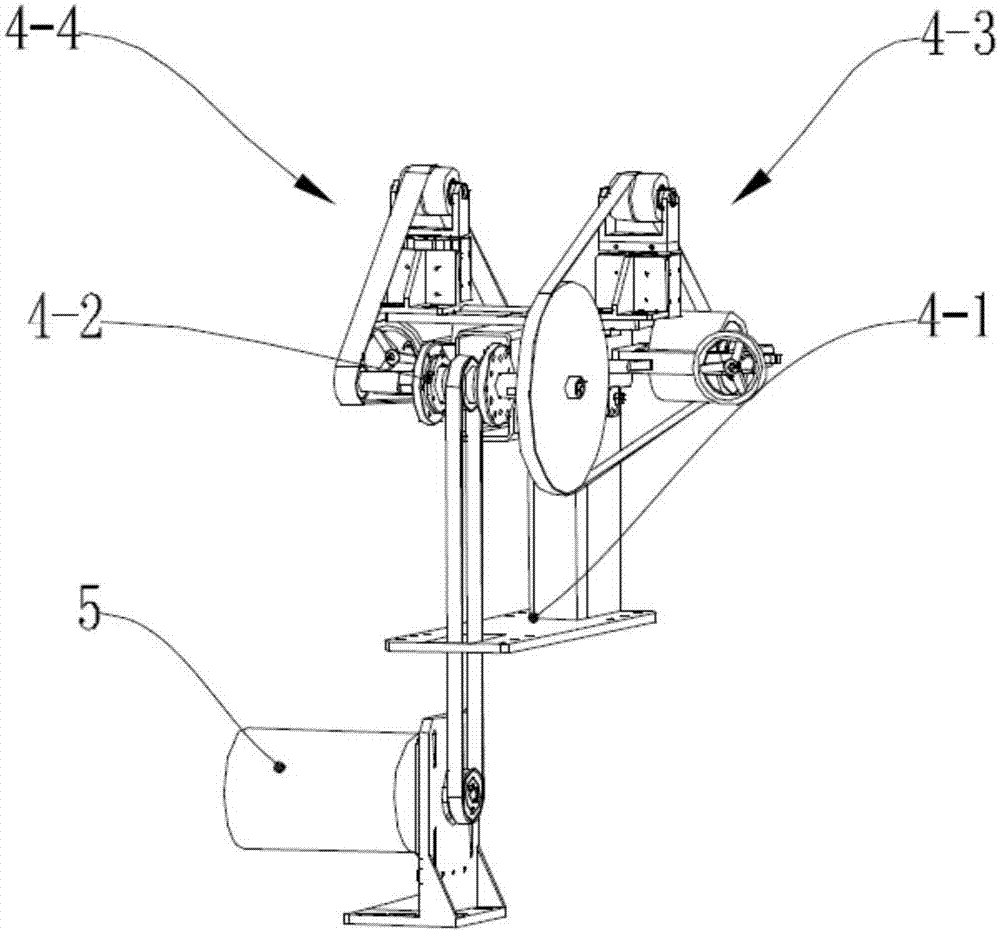

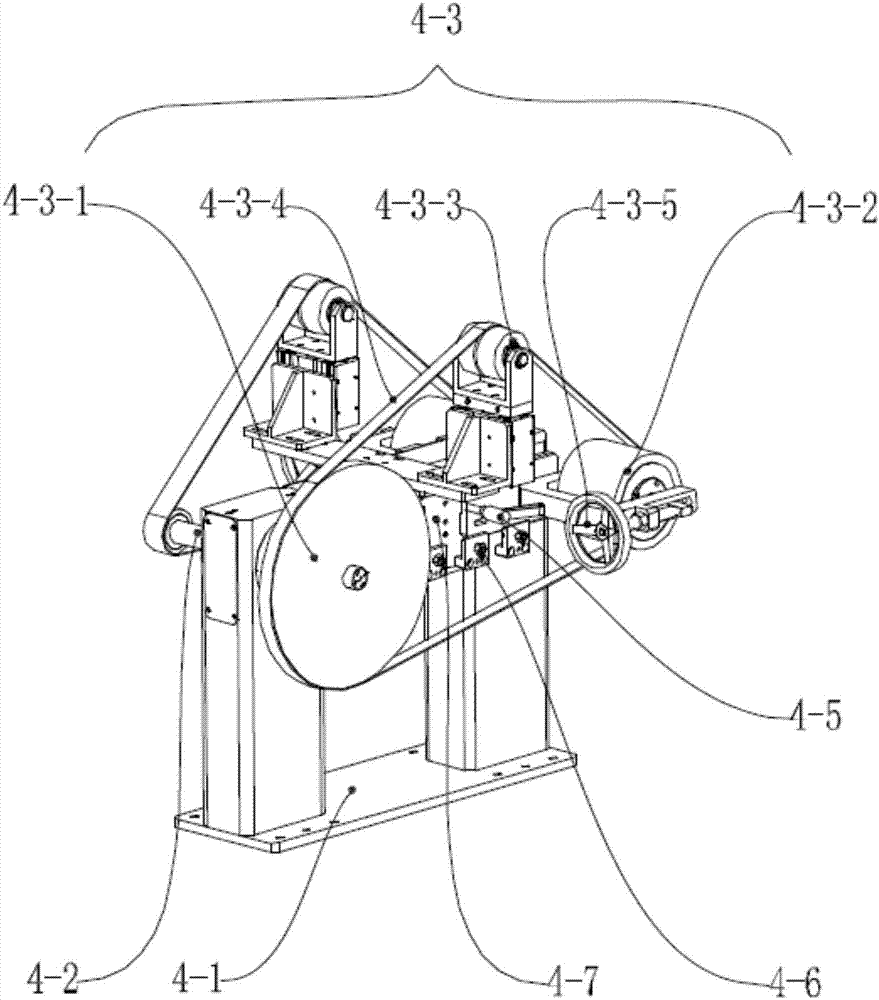

[0031] The single-drive grinding and polishing mechanism 4 is located in front of the free end of the mechanical arm 1 and includes a grinding mechanism 4-3 and a polishing mechanism 4-4. The PLC control system controls the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com