Degradable hyperbranched resin and preparation method and application thereof

A technology of hyperbranched resins and compounds, which can be used in biocide-containing paints, coatings, antifouling/underwater coatings, etc., and can solve the problem that the resin cannot be detached from the coating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

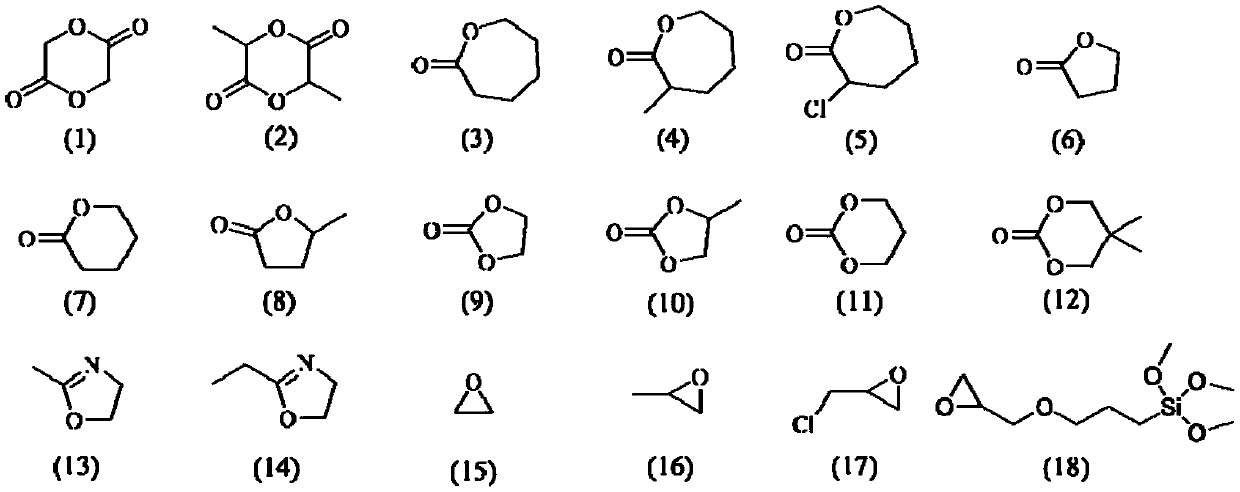

Method used

Image

Examples

Embodiment 1

[0062] Under the condition of stirring, add 50g of xylene and 40g of butyl acetate into the reaction vessel, raise the temperature to 100°C under a nitrogen atmosphere, and add 40g of acryloyloxytriisopropylsilane (purchased from Bailingwei) dropwise at a constant speed within 5 hours Technology Co., Ltd.), 30g of polyorthoesters with a molecular weight of 600g / mol of vinyl at both ends, 30g of 2-methylene-1,3-dioxo-4,5-benzocyclopentane, 1g of azobis A mixture of isobutyronitrile, 8g bis(thiobenzoyl) disulfide and 10g butyl acetate, after the dropwise addition, was incubated for 2 hours, and then 2g benzoyl peroxide and 10g benzoyl peroxide were added dropwise at a constant speed within 30 minutes. xylene, and stirred for another 4 hours to obtain a degradable hyperbranched silicon-based self-polishing resin.

[0063] The number average molecular weight Mn of the degradable hyperbranched silicon-based self-polishing resin in this embodiment is 6.5×10 3 g / mol, the silicon con...

Embodiment 2

[0065] Under the condition of stirring, 70g of propylene glycol methyl ether and 10g of ethyl acetate were added to the reaction vessel, and the temperature was raised to 100°C under a nitrogen atmosphere, and 10g of acryloyloxy tert-butyldimethylsilane ( (purchased from U.S. Momentive Company), 10g hydroxyethyl methacrylate, 30g phenyl acrylate, 25g tert-butyl methacrylate, 20g 2-methylene-1,3-dioxetane (purchased in Shanghai Aladdin Biochemical Technology Co., Ltd., CAS: 69814-56-8), 5g diacrylamide containing hydrazone structure, 15g tert-butyl peroxy-2-ethylhexanoate, 0.5g tetrakis (3-mercaptopropionic acid) The mixture of quaternetritol ester and 10g propylene glycol methyl ether is formed, after the dropwise addition is completed, it is incubated for 2 hours, and then 1g of tert-butyl peroxy-2-ethylhexanoate and 10g of dimethylbenzene are added dropwise at a uniform speed within 30 minutes, and then Stir for 2 hours to obtain a degradable hyperbranched silicon-based self...

Embodiment 3

[0068] (1) Synthesis of vinyl zinc ester monomer:

[0069] Add 13.6g of zinc hydroxide, 50g of toluene and 15g of isobutanol into the reaction vessel, and heat it to 75°C, add a mixture of 9.9g of acrylic acid and 41.4g of abietic acid dropwise at a constant speed for 3 hours, after the dropwise addition, keep the temperature for 2 hours , the solvent is removed by rotary evaporation to obtain the vinyl zinc ester monomer;

[0070] (2) Synthesis of degradable hyperbranched zinc-based self-polishing resin:

[0071] Under the condition of stirring, add 50g of xylene and 40g of butyl acetate into the reaction vessel, raise the temperature to 100°C under nitrogen atmosphere, add 60g of vinyl zinc ester functional monomer, 10g of N,N'-bis (Acryloyl)cystamine, 30g 2-methylene-4,7-dimethyl-1,3-dioxepane, 3g azobisisobutyronitrile, 8g bis(thiobenzoyl) The mixture of disulfide and 10g butyl acetate, after the dropwise addition, was incubated for 2 hours, 2g of benzoyl peroxide and 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com