Polishing device for carrying out hardware machining through micro-bubbles

A polishing device and micro-bubble technology, used in grinding/polishing safety devices, metal processing equipment, grinding drive devices, etc., can solve problems such as economic loss, poor equipment adaptability, and polishing wheel damage, and achieve the effect of avoiding aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

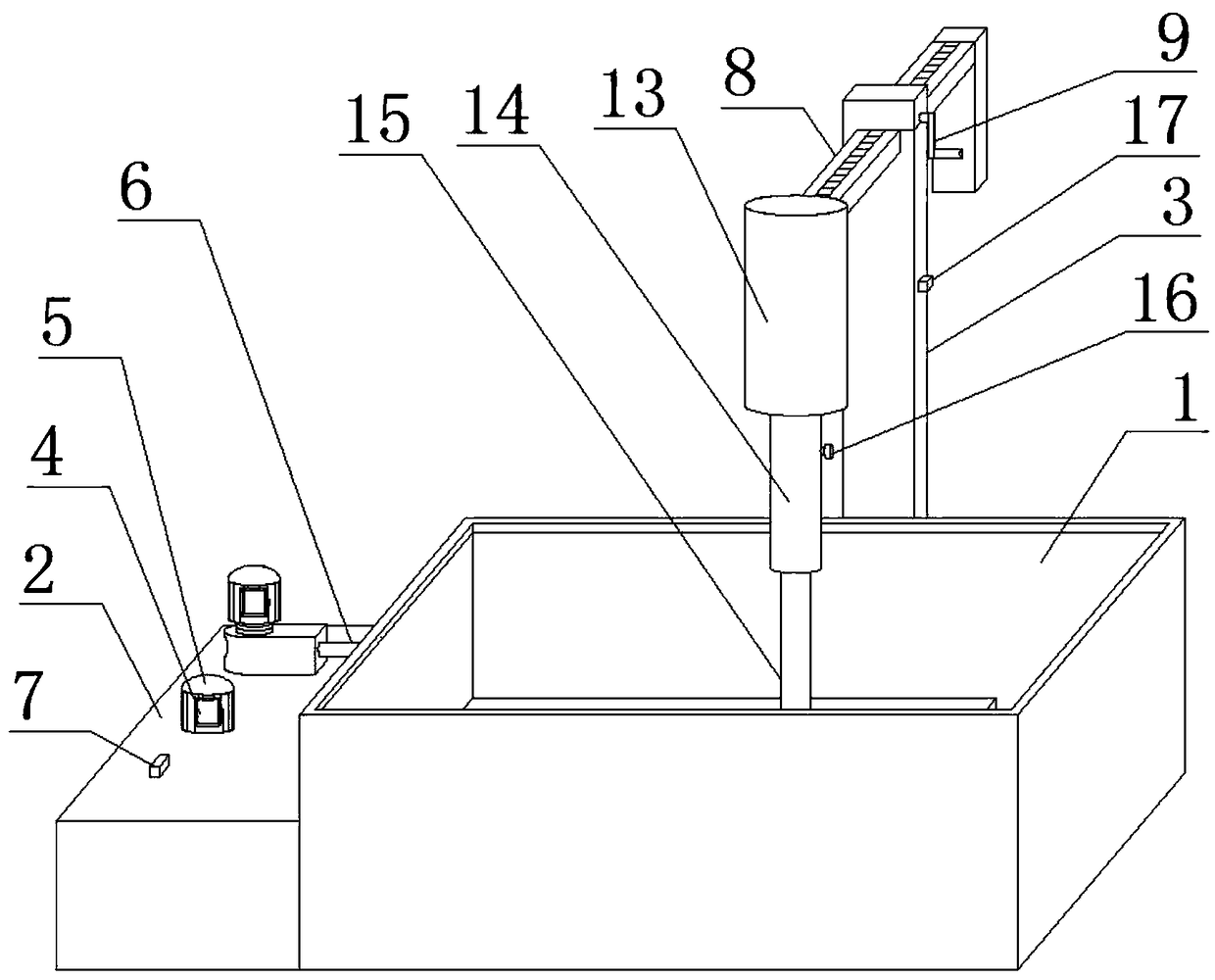

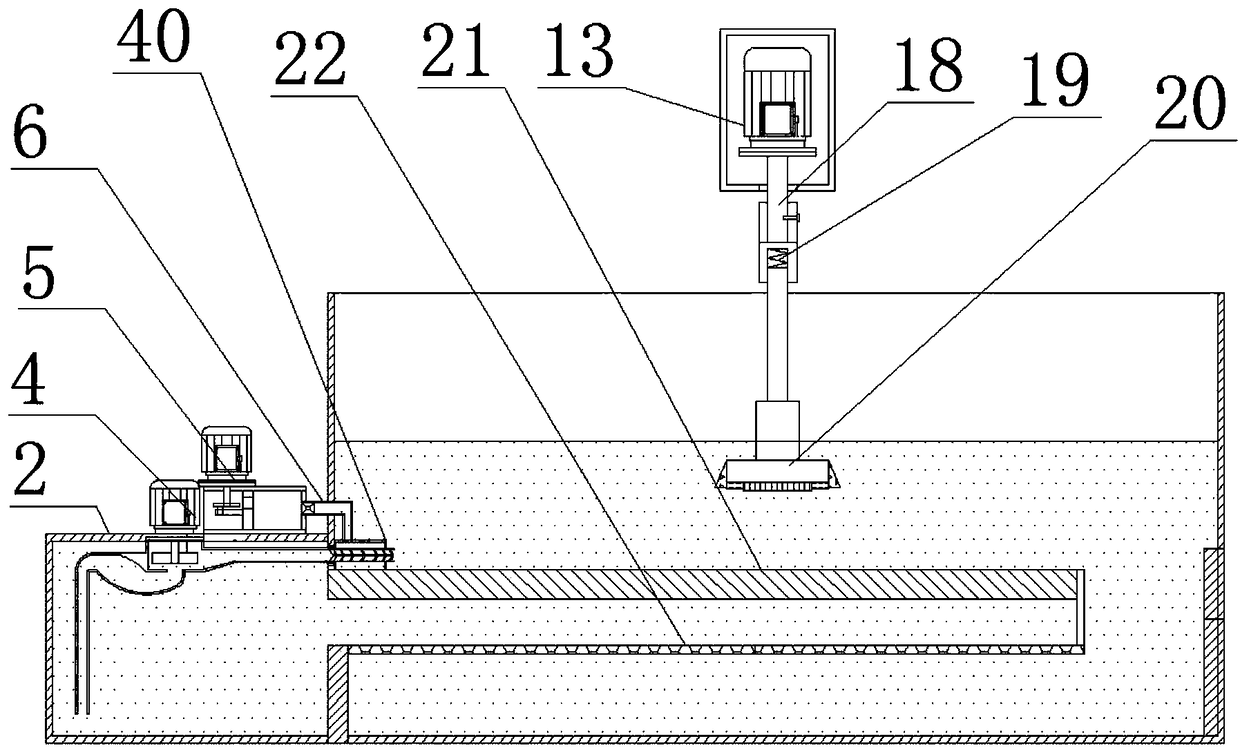

[0037] As a preferred embodiment of the present invention, one end of the water pump 4 is set at the bottom of the auxiliary tank 2, and the other end of the water pump 4 passes through the main tank 1 and extends to the top of the bottom plate 21. The bottom passes through the top of the auxiliary tank 2 and communicates with one side of the water pump 4.

[0038] As a preferred embodiment of the present invention, both the main tank 1 and the auxiliary tank 2 are provided with openings, the auxiliary tank 2 is in communication with the main tank 1 through the openings, and the bottom plate 21 is arranged on the top of the openings. , The filter plate 22 is arranged at the bottom of the port.

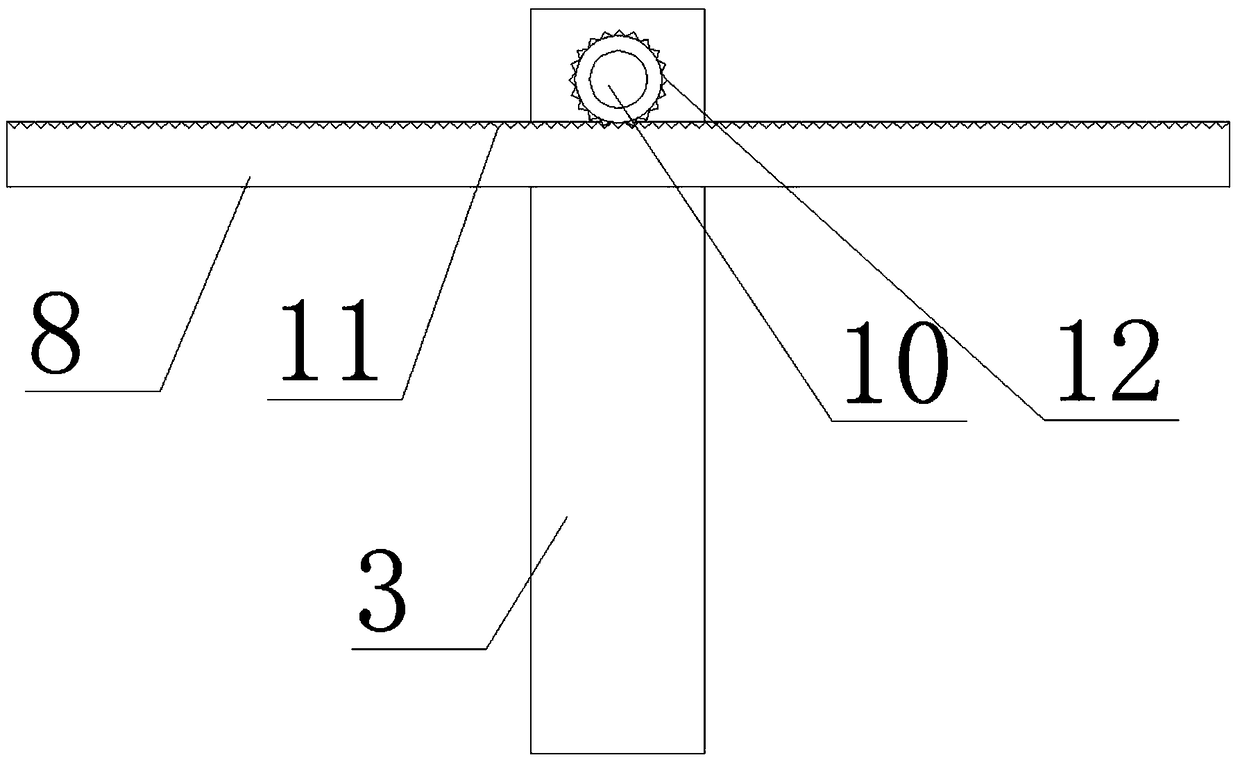

[0039] Working principle: The device provides electrical energy for all electrical equipment through an external power supply. When in use, first put the hardware products that need to be polished on the top of the bottom plate 21, and then turn the crank 9 to make the gear 12 and the tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com