Diamond grinding fluid dedicated for sapphire polishing and preparation method thereof

A technology of lapping fluid and sapphire, applied in the field of sapphire polishing, can solve the problem of easy precipitation of diamond powder, and achieve the effects of good dispersion, good suspension stability and environmental protection cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0028] White mineral oil (ml) Vegetable oil (ml) Diamond powder (g) Example 1 10 22 0.64 Example 2 15 26 0.78 Example 3 20 32 0.71 Example 4 25 30 0.30 Example 5 30 20 0.43 Example 6 17 35 0.95 Example 7 23 28 0.80 Example 8 35 15 1.00 Example 9 40 45 1.10 Example 10 32 40 1.20 comparative example Kerosene 30ml Vegetable oil 20ml Diamond powder 0.75g

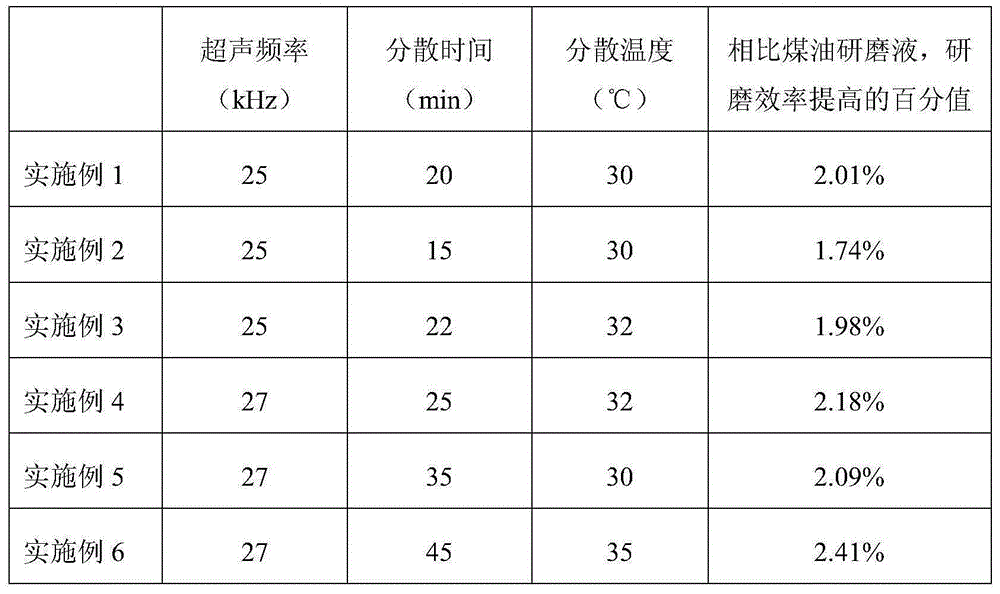

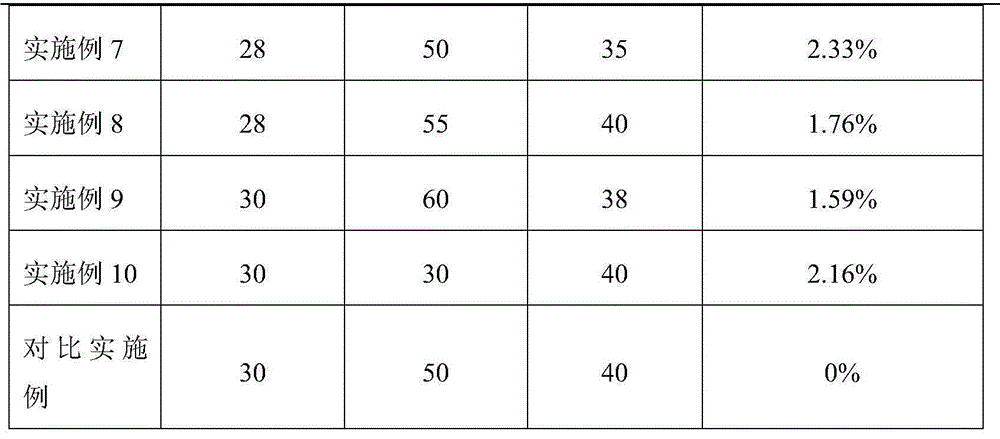

[0029] Take the concrete proportioning of above-mentioned embodiment 1-10, the process parameter of each embodiment is as shown in the following table:

[0030]

[0031]

[0032] Grinding efficiency refers to the time required to complete grinding under the same amount of raw materials and the same process parameters. When using the white mineral oil grinding liquid of the present application, the required grinding time is slightly shorter, which improves the working efficiency. Moreover, the safety accidents cause...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com