Profile end face polishing equipment

An end face and equipment technology, applied in the field of profile end face polishing equipment, can solve the problems of profile end face polishing defects, affecting the quality of equipment, etc., to achieve the effect of improving production efficiency, prolonging service life, and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

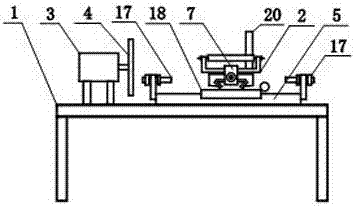

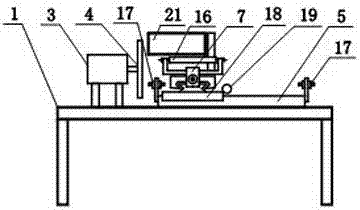

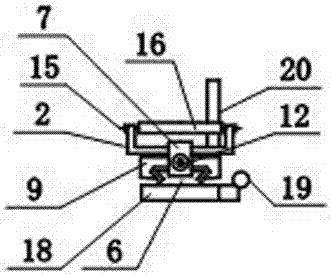

[0026] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , in the figure, 1-frame, 2-bracket, 3-motor, 4-polishing sheet, 5-first track, 6-second track, 7-baffle plate, 8-fixed plate, 9-second slider , 10-rising plate, 11-threaded hole, 12-adjusting rod, 13-thread, 14-U-shaped groove, 15-connecting rod, 16-bearing, 17-limit bolt, 18-first slider, 19- Operating lever, 20-limit post, 21-circular profile.

[0027] Profile end face polishing equipment, including a frame 1, a motor 3 and a bracket 2 arranged on the frame 1, a polishing sheet 4 is arranged on the motor 3, and two brackets 2 are arranged on the frame 1 through rails, and the rails Comprising a first rail 5 arranged on the frame 1 and a second rail 6 arranged on the first rail 5 and perpendicular to the first rail 5, the second rail 6 is slidably connected with the first rail 5 through the first slider 18 , the bracket 2 is slidingly connected with the second rail 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com