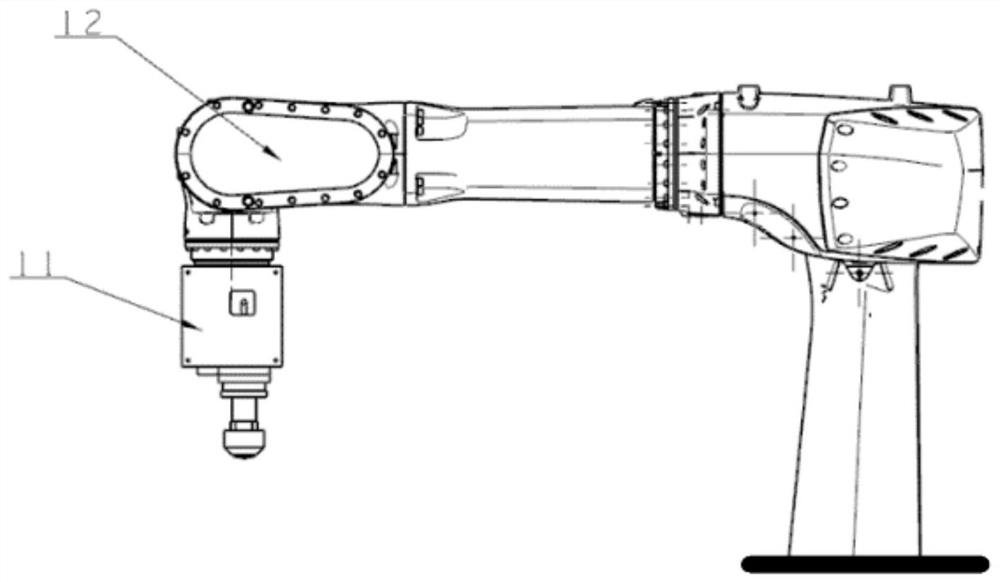

Robot air bag polishing device

An airbag polishing and robot technology, which is applied to grinding drive devices, grinding/polishing equipment, manipulators, etc., can solve the problems that the polishing effect cannot meet the requirements of polishing and cannot be trimmed, and achieve fast polishing and flexible displacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

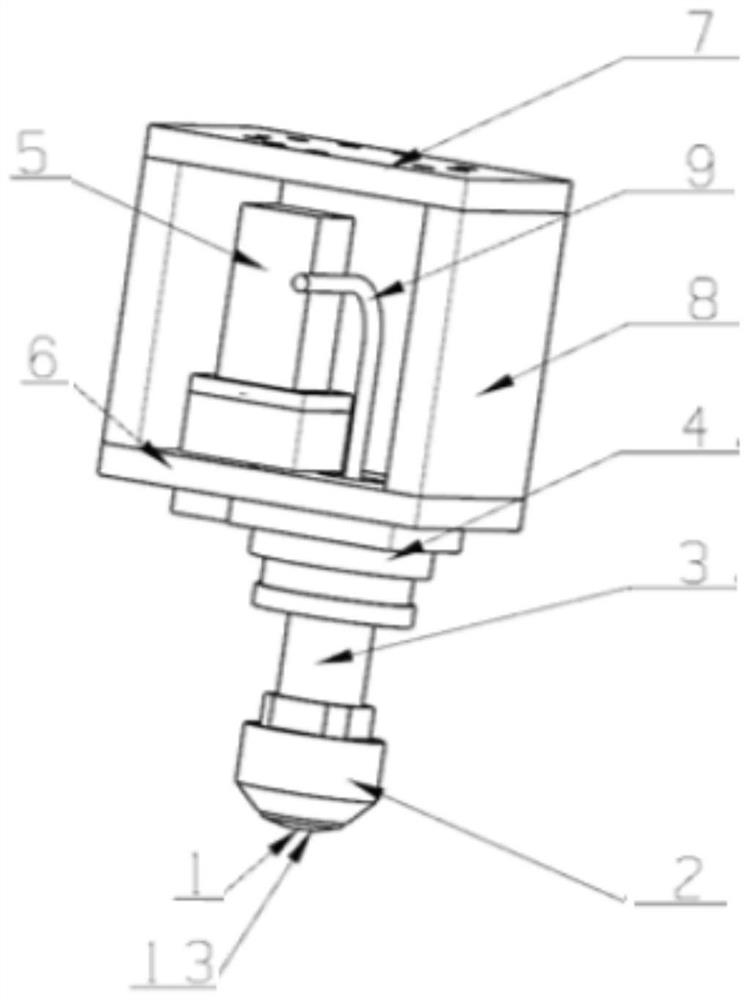

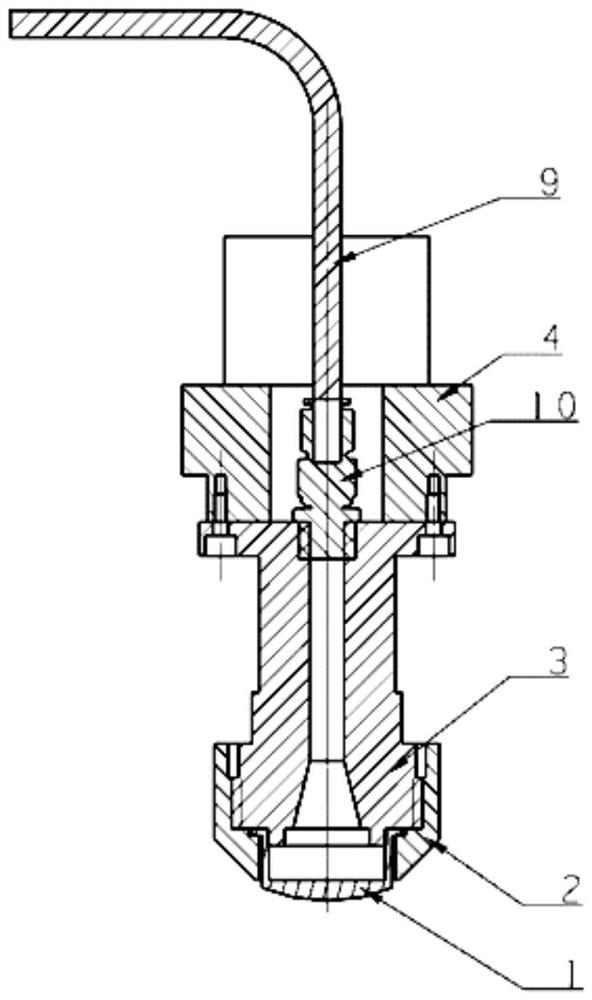

[0018] A robot airbag polishing device of the present invention includes a rubber grinding head, a base, a grinding head pressing block, a hollow rotating platform, a servo motor, a platform mounting plate, a six-axis robot mounting plate, a connecting plate, an air pipe, an air compressor, a high-speed Rotary joint, waterproof board, six-axis robot, polyurethane polishing sheet, the polyurethane polishing sheet is pasted on the rubber grinding head, the grinding head pressing block and the base are fixed through threaded connection, and the grinding head pressing block and the base clamp the rubber grinding head Tightly in the middle, the hollow rotating platform is installed on the platform mounting plate, one end of the platform mounting plate is connected to the base, the other end of the platform mounting plate is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com