Ultrasonic magneto-rheological chemical composite polishing device and method

A composite polishing and magnetorheological technology, which is used in grinding/polishing safety devices, grinding/polishing equipment, machine tools with surface polishing, etc. Safety hazards and other issues, to achieve the effect of increasing mechanical removal performance, improving uniformity and efficiency, and improving polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

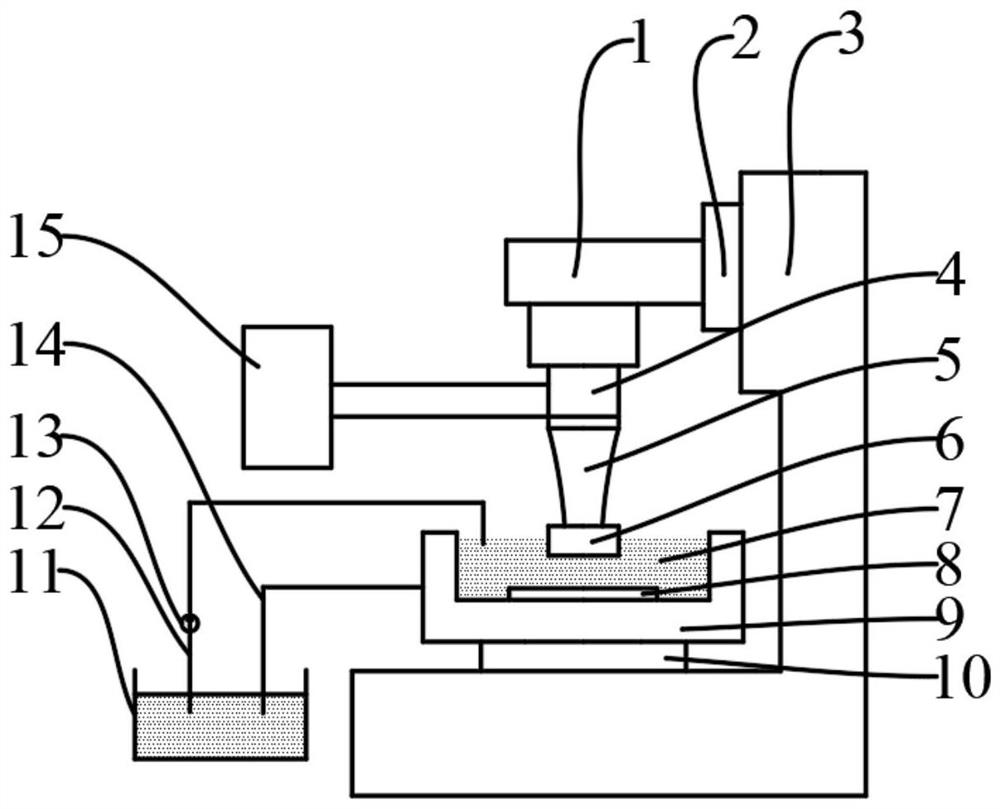

[0039] like Figure 1-2 As shown, an ultrasonic magneto-rheological compound polishing device includes a frame 3 and a cup-shaped polishing disc 9 arranged on the frame 3, a magnetorheological tool head 6 and an ultrasonic vibration mechanism, and the cup-shaped polishing disc 9 It is used to hold the working fluid, and the workpiece 8 to be polished is placed in the cup-shaped polishing disc 9, and the cup-shaped polishing disc 9 can move back and forth horizontally relative to the frame 3. The magnetorheological tool head 6 is located directly above the cup-shaped polishing disc 9 and has magnetism, and the ultrasonic vibration mechanism includes an ultrasonic generator 15, an ultrasonic transducer 4 electrically connected to the ultrasonic generator 15, and an output of the ultrasonic transducer 4 The ultrasonic horn 5 on the end, the ultrasonic horn 5 is arranged up and down, the ultrasonic transducer 4 is arranged on the upper end of the ultrasonic horn 5, and the magneto...

Embodiment 2

[0049] This embodiment is a method for polishing a single crystal SiC substrate by using the polishing device in Embodiment 1.

[0050] The method comprises the steps of:

[0051] Step 1: Configure the working solution.

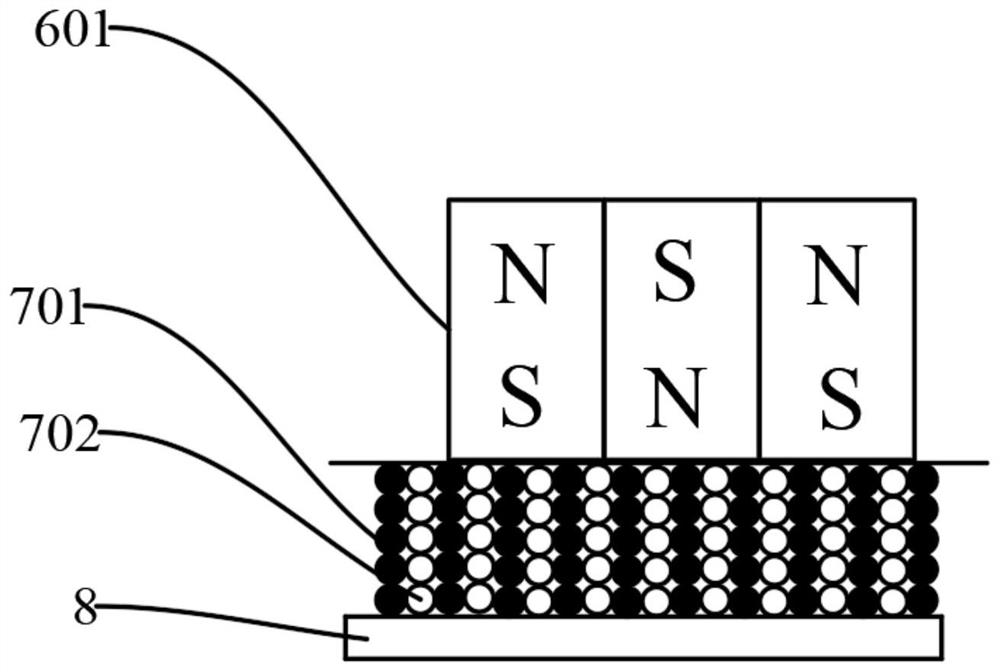

[0052] Specifically, the working fluid uses deionized water as the basic carrier liquid, and 100nm-1000nm diamond 702, 5 μm-10 μm carbonyl iron powder 701, glycerin, and hydrogen peroxide solution are added to the deionized water, and the pH value is adjusted after fully stirring for 2. Wherein, the diamond 702 is abrasive particles, glycerin is used as a stabilizer, and hydrogen peroxide solution is used as an oxidizing agent.

[0053] Step 2: Fix the workpiece 8 in the cup-shaped polishing disc 9 , control the Z-axis slide assembly 2 , and adjust the machining gap between the magneto-rheological tool head 6 and the workpiece 8 . The fixing method of the workpiece 8 in the cup-shaped polishing disc 9 can be pasted, or other methods in the prior art can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com