Apparatus and method for polishing an edge of an article using magnetorheological (MR) fluid

A magnetorheological fluid and magnetorheological technology, applied in the field of edge devices, can solve the problems of not being able to provide material removal rate and not suitable for removing subsurface microcracks, and achieve the effect of increasing material removal rate and reducing polishing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

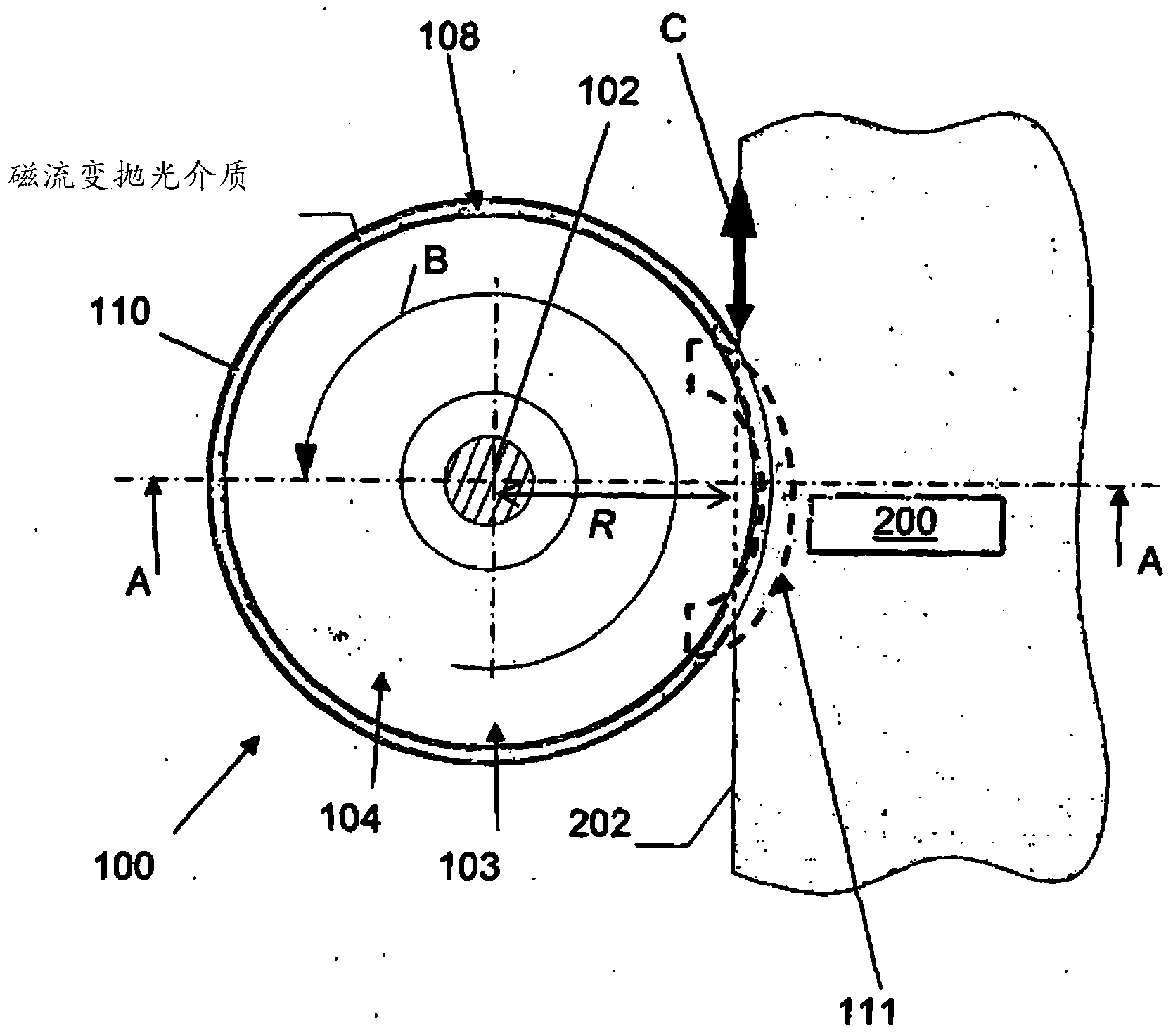

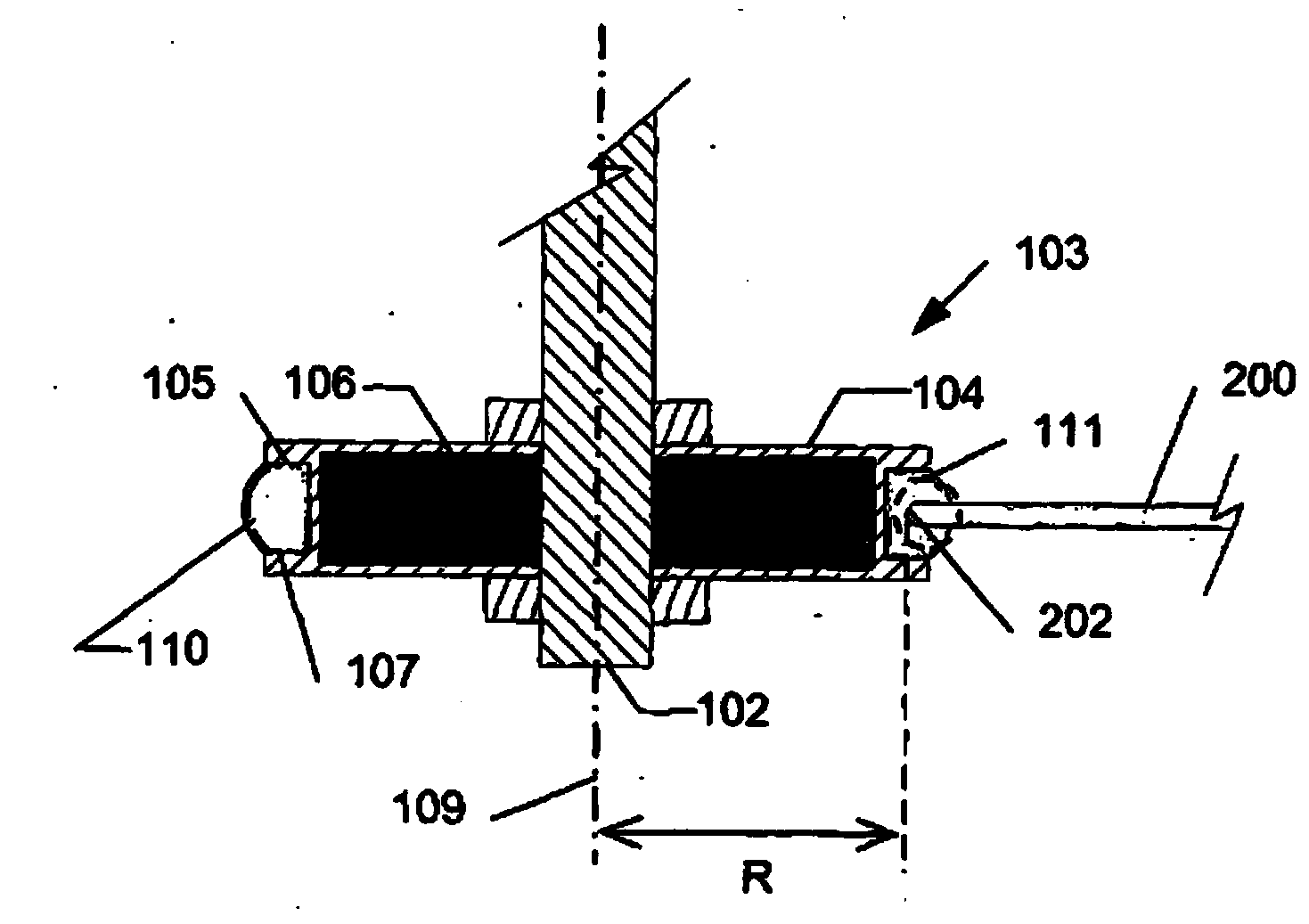

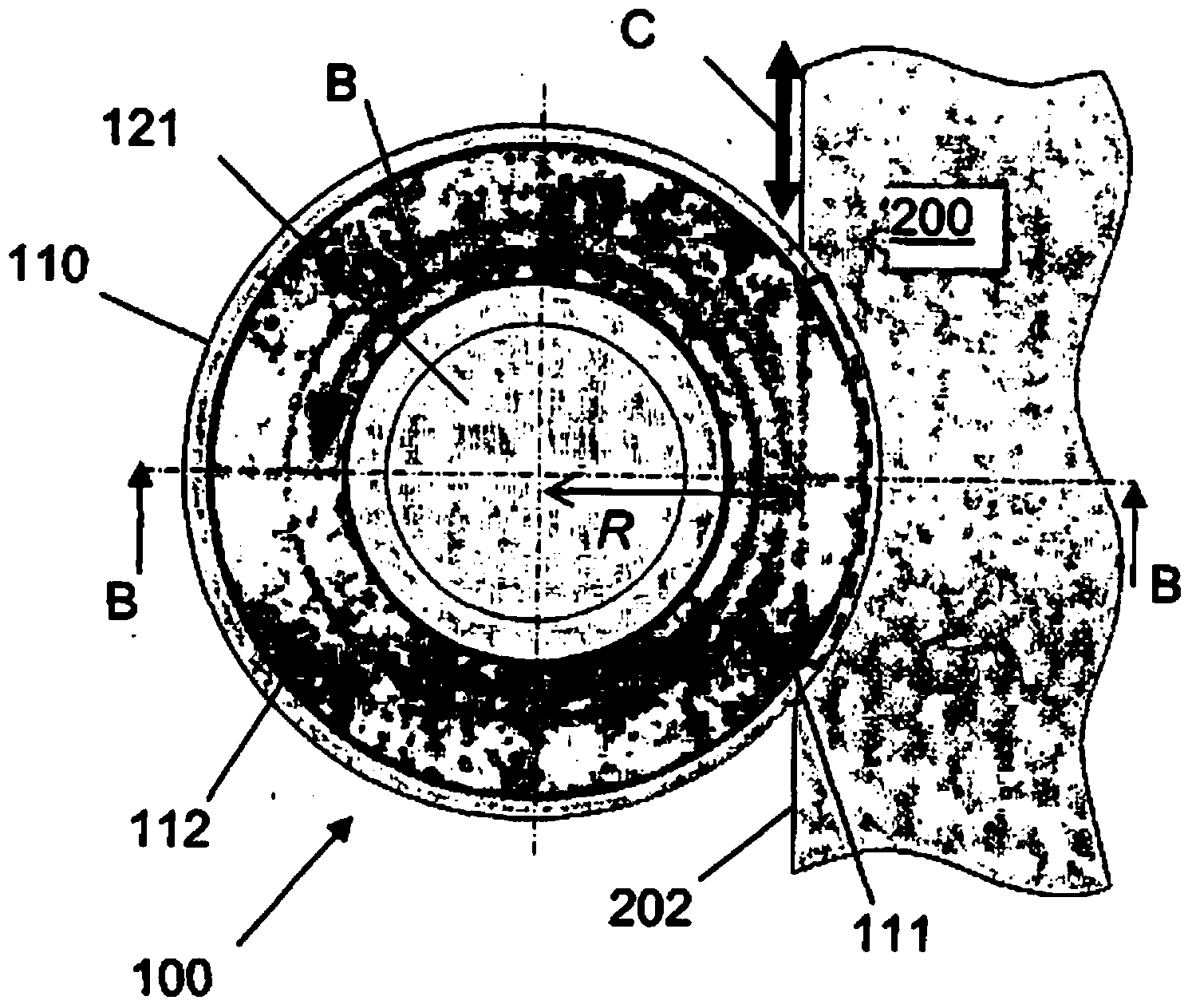

[0037] In order to understand the advantages of embodiments of the present invention, it is advantageous to first explain the various parameters that may affect the material removal rate of a magneto-rheological polishing (MRF) process.

[0038] It has been found that, tribologically, the MRF process is a combination of two and three body abrasive wear. Therefore, the process equations discussed below apply to the MRF process:

[0039] R a = ( R i - R ∞ ) · e - k T p a v H t + R ∞ -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com